products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Roll to Roll Transfer Coating System with Drying Oven For Battery Electrodes

Model Number:

TMAX-TB300-SInput Power:

15kwDimension(L*W*H):

2500*1060*1200mmCompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

Fujian, China (Mainland)Shipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

High Quality Double Blade Micrometer Film Applicator With Width of 150 mmNext:

Micrometer Film Applicator with Adjustable Width 0 - 150 mm

Roll to Roll Transfer Coating System with Drying Oven For Battery Electrodes

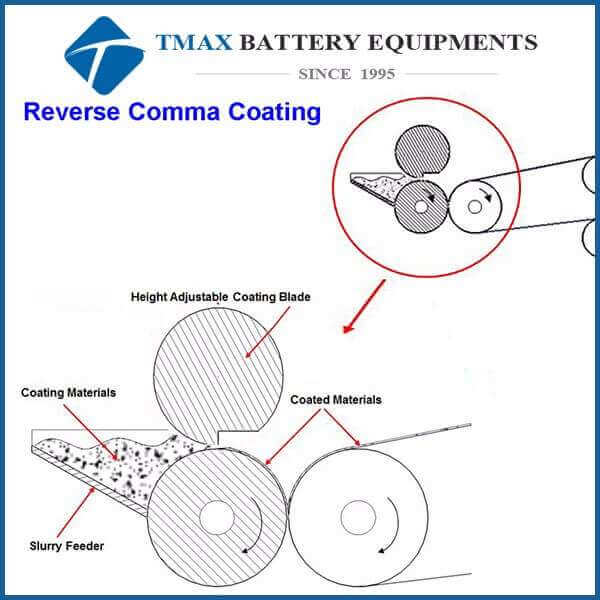

TMAX-TB300 is a CE Certified and UL ready automatic battery electrode coating system. It uses transfer coating technique for better coating uniformity and is perfect for research or building prototypes (e.g. pilot scalestudies) of new generation rechargeable batteries. It is integrated with the functions/ features of metallic foil roll unwinding (reeling out), slurry feeder, coating blade, baking oven, and final electrode winding (reeling in)together with touch screen operation for customer's utmost convenience. Get expert advice about Roll to Roll Coater here.

Specifications:

Working Voltage |

208 - 240 V AC, 50/60Hz, Single Phase |

Max. Power Consumption |

Max15KW |

Max. Coating Width |

280mm |

Coating Speed |

0-1000 mm / minute |

Thickness Precision |

± 3µm (± 5µm at edges) |

Max. Drying Temperature |

150°C max |

Temperature Accuracy |

±1°C |

Heating Zone Length |

1600mm |

Reeling/Unreeling Shaft |

75mm (ID) |

Max. Reeling/UnreelingDiameter |

250mm (OD) |

Max. Coating Length |

1. Depending on the coating and substrate thickness. 2. Typically, 10um thick foil with 100um coating can get 600 meters of electrodelength coated per run |

Coating Modes |

3. Using transfer coating technique (Doctor Blade Coating) for better uniformity 4. Two available coating modes selectable on the control panel. 1. Continuous mode 2. Intermittent coating ( system performs coating, stops, coats again and so on.The length of the coating and break segments can be specified by the user ). |

Slurry Stirring |

SS316 Moving Rod |

Exhaust Port Size |

100mm O.D |

Compressed Air |

0.5-0.8 MPa |

Product Dimensions |

2500*1060*1200mm |

Net Weight |

1300kg |

Compliance |

CE Certificate |

Warranty |

One Year limited warranty with lifetime support |

Application Notes |

Please use Acetone to clean and dry the doctor blade, slurry feeder, and roller toavoid rusting |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588