products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Precision Energy Storage Spot Welder

Model Number:

TMAX-DH-20018Input Power:

360WDimension(L*W*H):

1000L*600W*1310H (mm)Net Weight:

120KGCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportUpdate:

OptionalShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Single-side Rotary Welding Head Automatic Numerical Control Spot Welding Machine for Storageable NCM Lithium Battery Module WeldingNext:

5000A or 8000A Medium Frequency Butt Welder/ Inverter Resistance Welder /18650 Power Battery Spot Welder

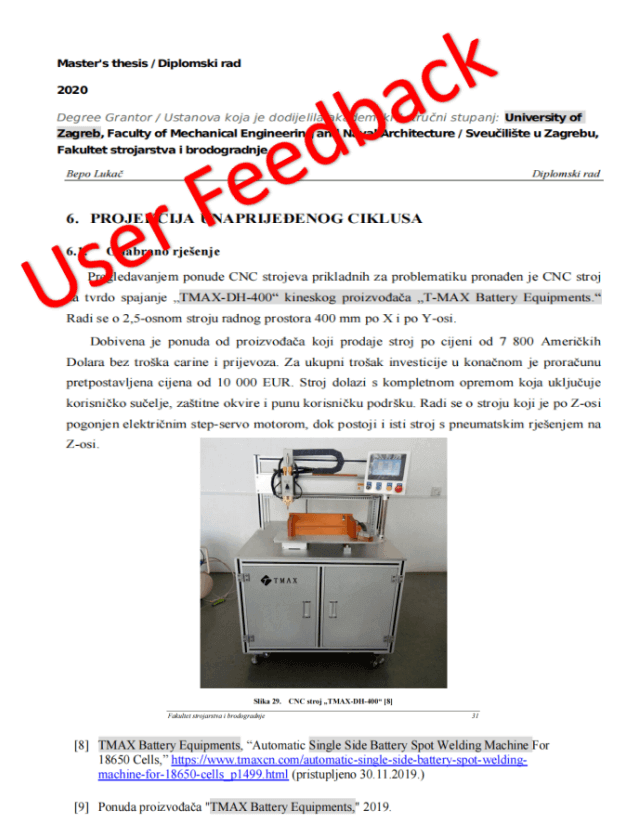

Precision Energy Storage Spot Welder

Product overview:

Energy saving and high efficiency: low instantaneous power, high power factor, small impact on the power grid, energy saving, stable output voltage, good consistency; solid welding, no discoloration of welding points, saving grinding process, high efficiency, widely used for clock particles and welding, battery connector, hardware, etc

Characteristic:

1. The control performance of microcomputer CPU with DC inverter technology is particularly stable, and the setting is simple and convenient.

2. The pressure knob is made according to the international standard customer. The pressure of two welding pins is even, which will not cause faulty welding, and the welding accuracy is higher.

3. The short welding time with the traditional AC pulse capacitor welding machine has no effect on the internal characteristics of the cell, the change of the internal resistance of the battery, the voltage and capacity.

4. After welding, the battery surface is cleaner, with small burr, very small welding spark, and no blackening of welding spot.

5. The blue LCD screen graphically displays the current working status, with clear interface, beautiful appearance and more humanization.

6. The power supply has strong adaptability, will not cause interference to the power grid, and the welding is firm.

Specification:

Name |

Precision Energy Storage Spot Welder |

Input power |

AC380±10%, 50/60HZ |

Power consumption |

360W |

Outline size |

1000L*600W*1310H (mm) |

Overall weight of equipment |

120KG |

Maximum output power of transformer |

35KVA |

Maximum short circuit output current |

8000A |

Rated capacity |

500J |

Welding voltage adjustment |

50-350VDC |

Welding time |

1.0mS-20.0mS adjustable, accuracy: 0.1mS |

Number of welding pulses |

2 |

Welding needle configuration |

1.8mm/3mm/6mm |

Adjustable distance between welding needles |

0-20mm |

Welding speed |

0.5-0.8S/single welding |

Welding thickness |

0.08-0.3mm nickel plated strip(Planar) 0.2-0.5mm nickel plated strip (Bump) |

Parameters can be stored |

10 groups |

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588