products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

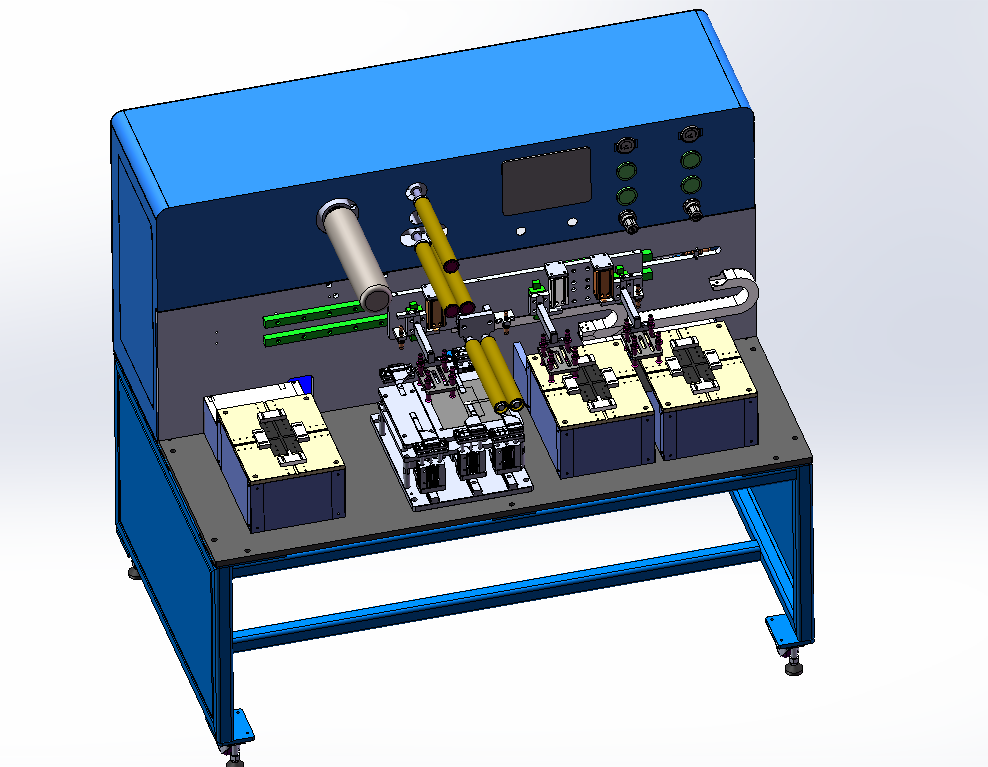

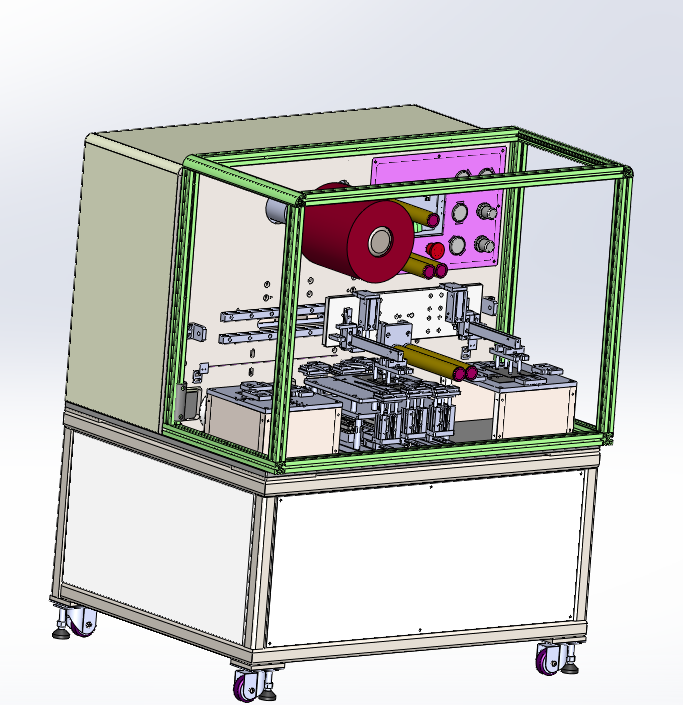

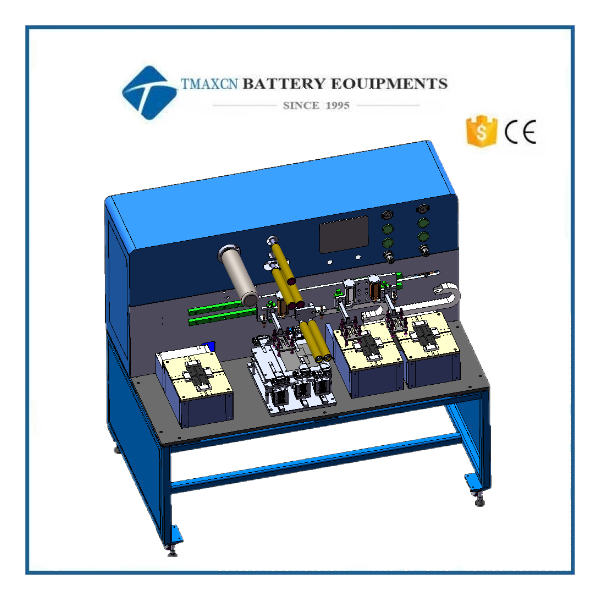

Pouch Cell Stacking Machine for Solid State Battery with Three Magazines

Model Number:

TMAX-111A-DCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Pressure-Controlled Solid-State Battery Mold Test KitNext:

Solid State Battery Hot Press Formation Machine

Pouch Cell Stacking Machine for Solid State Battery with Three Magazines

The TMAX-111A-D is primarily used for the Z-fashion stacking assembly of cell electrodes and solid electrolyte. This equipment enables manual loading of pieces, by fully automatic alignment and stacking processes, offering high stacking efficiency and precision. It is designed to stack battery cells up to 160*160/300*300mm, with adjustments available for different sizes via interchangeable fixtures, making it highly suitable for the development and sample production of stacked solid state battery. The equipment features a single-arm structure, automatic constant tension control for the separator roll, and automatic correction control.

Features

*The number of stacking layer can be automatically controlled according to the preset;

*The compatibility design is adopted, and the change of battery size can be realized by adjusting the positioning fixture, with a large adjustment range;

*PLC control, HMI operation, easy to use and maintain;

*Electrode manual loading, automatic positioning, manipulator automatic suction and automatic stacking;

*Separator automatic servo constant tension control.

*Separator automatic photoelectric correction control.

Technical parameters

Working Voltage |

AC220V/110V, 50/60Hz |

Power |

0.6kw |

Stacking mode |

Z fashion |

Operation mode |

Manual feeding, manipulator picking up electrodes automatically, automatic separator pulling |

Stacking accuracy |

≤±0.3mm |

Stacking size range |

Min.L40mm *W40mm, Max. L160mm*W160mm(standard) Larger compatible size is available upon request at extra cost |

Stacking thickness |

Max.10mm |

Number of stacking |

Max. 100 layers adjustable |

Separator coil diameter |

Max. 250mm |

Separator core |

3-inch roll core, air expansion shaft clamping |

Tension control |

Automatic servo constant tension control |

Separator correction |

Automatic photoelectric correction control |

Machine dimensions |

L1000mm*W780mm*H750mm |

weight |

About 400Kg |

Gas source |

0.5~0.8MPa compressed air |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588