products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

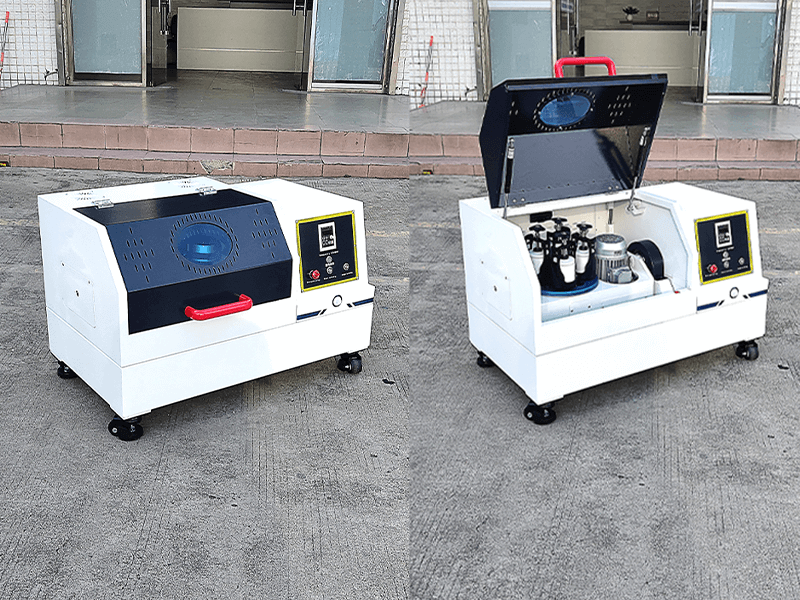

Miniature Omni-directional Planetary Ball Mill

Model Number:

TMAX-OPBMInput Power:

0.75KWDimension(L*W*H):

750*470*564mmNet Weight:

80KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Miniature Omni-directional Planetary Ball Mill

Planet flipping mechanism

Planetary transmission mechanism through the rotation of the motor to do 360 degrees around the axis, can realize any angle positioning for different process requirements ball grinding, safe and reliable.

The control panel

Frequency conversion speed control, high speed accuracy, with undervoltage, over current, overload protection, optional 4.5-inch touch screen setting free and program mode, program storage is very convenient.

Self-lubricating device

Through the electronic control of lubrication host, flexible design of time cycle automatic and quantitative grease, to solve the problem of wear caused by not timely lubrication of transmission components, shorten the service life of equipment.

Induction lamp energy device

The energy-saving device is controlled by infrared human body sensor, the lamp will be bright when people come, and the lamp will go off after dozens of seconds, which is both energy-saving and convenient.

Introduction

The omnidirectional planetary ball mill is based on the vertical planetary ball mill and adds the function of planetary transmission mechanism. 360° flip, realize the multi-dimensional and multi-directional movement of the grinding ball and the material in the ball milling tank, and improve the degree of disordered movement of the grinding ball and the material. The material can be more uniform, and it can solve the problem of some materials sinking to the bottom and sticking to the tank.

Product character

Mode of transmission |

Gear transmission |

Mode of working |

Two and four ball grinding jars work simultaneously |

Maximum loading capacity of materials |

Two thirds of the volume of the ball mill jar |

Ball mill tank volume |

0.05-10L per jar, total volume 0.2-40L |

Feed granularity |

Soil material≤10mm, and other materials≤3mm |

Granularity of discharge |

Up to 1 micron |

Mode of speed regulation |

Infinitely adjustable-speed |

Model |

Volume |

Configurable ball mill specifications |

Qty |

Configurable vacuum ball mill volume |

Locking device |

OPBM-0.4 |

0.4 |

50-100ml |

4 |

50ml |

automatic |

OPBM-1 |

1 |

50-250ml |

4 |

50-100ml |

automatic |

OPBM-2 |

2 |

50-500ml |

4 |

50-250ml |

automatic |

OPBM-4 |

4 |

250-1000ml |

4 |

50-500ml |

automatic |

OPBM-6 |

6 |

1-1.5L |

4 |

50-1000ml |

automatic |

OPBM-8 |

8 |

1-2L |

4 |

50-1500ml |

automatic |

OPBM-10 |

10 |

1-2.5L |

4 |

1-2L |

automatic |

OPBM-12 |

12 |

1-3L |

4 |

1-2L |

automatic |

OPBM-16 |

16 |

2-4L |

4 |

1-3L |

automatic |

OPBM-20 |

20 |

2-5L |

4 |

2-4L |

automatic |

OPBM-40 |

40 |

5-10L |

4 |

4-5L |

automatic |

OPBM-60 |

60 |

10-15L |

4 |

5-10L |

automatic |

OPBM-80 |

80 |

15-20L |

4 |

10-15L |

automatic |

OPBM-100 |

100 |

20-25L |

4 |

15-20L |

automatic |

Model |

Power supply |

Power(kw) |

Rotary motor power(KW) |

Total time to run the set(min) |

Alternating positive and negative running time(min) |

Adjustable speed Revolution(rpm) Rotation(rpm) |

|

OPBM-0.4 |

220V-50HZ(single-phase) |

0.75 |

0.09 |

1-9999 |

1-9999 |

47-465 |

94-930 |

OPBM-1 |

220V-50HZ(single-phase) |

0.75 |

0.09 |

1-9999 |

1-9999 |

35-370 |

70-740 |

OPBM-2 |

220V-50HZ(single-phase) |

0.75 |

0.09 |

1-9999 |

1-9999 |

35-370 |

70-740 |

OPBM-4 |

220V-50HZ(single-phase) |

0.75 |

0.09 |

1-9999 |

1-9999 |

35-370 |

70-740 |

OPBM-6 |

220V-50HZ(single-phase) |

0.75 |

0.12 |

1-9999 |

1-9999 |

35-370 |

70-740 |

OPBM-8 |

220V-50HZ(single-phase) |

1.5 |

0.12 |

1-9999 |

1-9999 |

35-320 |

70-640 |

OPBM-10 |

220V-50HZ(single-phase) |

1.5 |

0.12 |

1-9999 |

1-9999 |

35-320 |

70-640 |

OPBM-12 |

220V-50HZ(single-phase) |

1.5 |

0.12 |

1-9999 |

1-9999 |

35-320 |

70-640 |

OPBM-16 |

380V-50HZ(three-phase) |

3 |

0.12 |

1-9999 |

1-9999 |

30-255 |

60-510 |

OPBM-20 |

380V-50HZ(three-phase) |

4 |

0.75 |

1-9999 |

1-9999 |

25-215 |

50-430 |

OPBM-40 |

380V-50HZ(three-phase) |

5.5 |

0.75 |

1-9999 |

1-9999 |

20-195 |

40-390 |

OPBM-60 |

380V-50HZ(three-phase) |

7.5 |

1.1 |

1-9999 |

1-9999 |

27-174 |

40-260 |

OPBM-80 |

380V-50HZ(three-phase) |

11 |

1.5 |

1-9999 |

1-9999 |

27-160 |

40-240 |

OPBM-100 |

380V-50HZ(three-phase) |

11 |

1.5 |

1-9999 |

1-9999 |

40-240 |

|

Model |

Standard panel (optional touch screen) |

Lubrication way(optional automatic grease-adding device) |

Mode of speed regulation |

Weight(kg) |

Size(Length * width * height) |

Noise≤db |

OPBM-0.4 |

intelligent |

grease |

Frequency control |

140 |

900*570*650 |

55±5 |

OPBM-1 |

intelligent |

grease |

Frequency control |

280 |

1330*770*810 |

60±5 |

OPBM-2 |

intelligent |

grease |

Frequency control |

280 |

1330*770*810 |

60±5 |

OPBM-4 |

intelligent |

grease |

Frequency control |

285 |

1330*770*810 |

60±5 |

OPBM-6 |

intelligent |

grease |

Frequency control |

290 |

1330*770*810 |

60±5 |

OPBM-8 |

intelligent |

grease |

Frequency control |

345 |

1350*850*900 |

60±5 |

OPBM-10 |

intelligent |

grease |

Frequency control |

345 |

1350*850*900 |

65±5 |

OPBM-12 |

intelligent |

grease |

Frequency control |

350 |

1350*850*900 |

65±5 |

OPBM-16 |

intelligent |

grease |

Frequency control |

400 |

1550*940*1050 |

65±5 |

OPBM-20 |

intelligent |

grease |

Frequency control |

710 |

1700*1200*1250 |

68±5 |

OPBM-40 |

intelligent |

grease |

Frequency control |

1000 |

1900*1450*1400 |

68±5 |

OPBM-60 |

intelligent |

grease |

Frequency control |

2180 |

2150*1750*2090 |

68±5 |

OPBM-80 |

intelligent |

grease |

Frequency control |

2400 |

2300*1900*2140 |

68±5 |

OPBM-100 |

intelligent |

grease |

Frequency control |

2400 |

2300*1900*2140 |

68±5 |

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588