products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Large Versatile Roll to Roll Pilot Coating Machine

Model Number:

TMAX-AFA-MC400Dimension(L*W*H):

L6800mm x W1200mm x H1900mm Can be customizedCompliance:

CE CertifiedWarranty:

Two Year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Large Versatile Roll to Roll Pilot Coating Machine

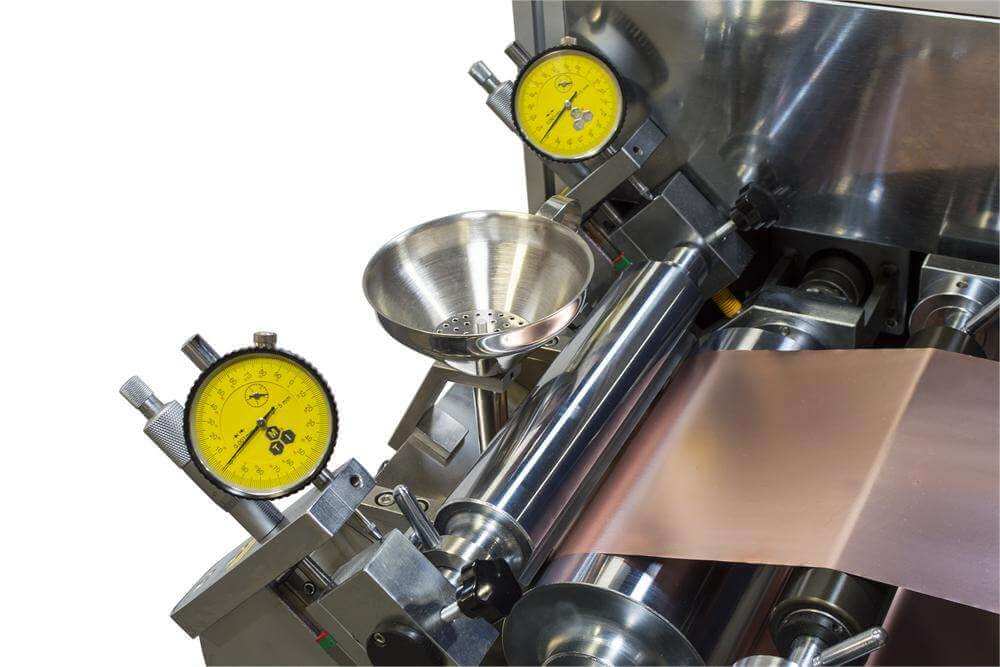

TMAX-AFA-MC400 is a versatile roll to roll coating machine system which can adapt various coating heads such as reverse comma blade, Doctor Blade, Slot Die and Micro Gravure and Tape Casting. A 4.5 meters long, three zone convection drying oven with independent temperature programming is implemented for efficient slurry curing. This is the most complete and universal pilot coating system that provides a broad adaptability to various coating slurries and film substrates (Cu, Al, PET, PP, PE).

- Doctor Blade: Cost effective solution for 8~200 micron thick coatings (Continuous mode only)

- Reverse Comma Blade (Transfer Coating): Cost

effective solution for 30~200 micron thick coatings (Both continuous

& intermittence mode)

- Tape Cast Coating: Ideal for performing

thicker coating up to 1000 microns with high viscosity slurry

- Micro-Gravure: Perfectly suitable for precise

thin coatings from 1~3 microns (dry

film thickness)

- Slot Die: Suitable for precision coatings as thin as 1 micron while providing a wide coverage for thicker coatings upto 200 microns

Specifications:

| Working Voltage |

110 - 240 VAC, 50/60

Hz, three Phase (380VAC three phase is available upon request) |

|

| Max. Power Consumption |

30-35 KW ( 50A Air

breaker required ) |

|

| Compressed Air |

0.5-0.9 MPa is required (Air

compressor not included. |

|

| Reeling/Unreeling

Diameter |

|

|

| Coating Width |

350mm Max. |

|

| Coating Speed |

Max.5000mm/min |

|

| Coating Heads

|

Doctor Blade Coating |

|

| Reverse Comma Blade

(Transfer Coating) |

|

|

| Cast Coating |

|

|

| Slot Die coating |

Attention: The final

coating thickness is dependent on a wide range of parameters such as slurry

viscosity, solid particle size, solid content, shim thickness, foil rolling

speed and slurry feeding rate. Therefore, we are not able to guarantee that

1-micron level film is achievable for all kinds of slurries. For further

discussion, please let us know your slurry specs and coating thickness

requirement. |

|

| Micro-Gravure Coating |

|

|

| Convection Drying

Oven |

|

|

| Product Dimensions |

L6800mm x W1200mm x

H1900mm |

|

| Compliance |

|

|

| Warranty |

|

|

| Application Notes |

|

|

| Net Weight |

13t |

|

![]()

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588