products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

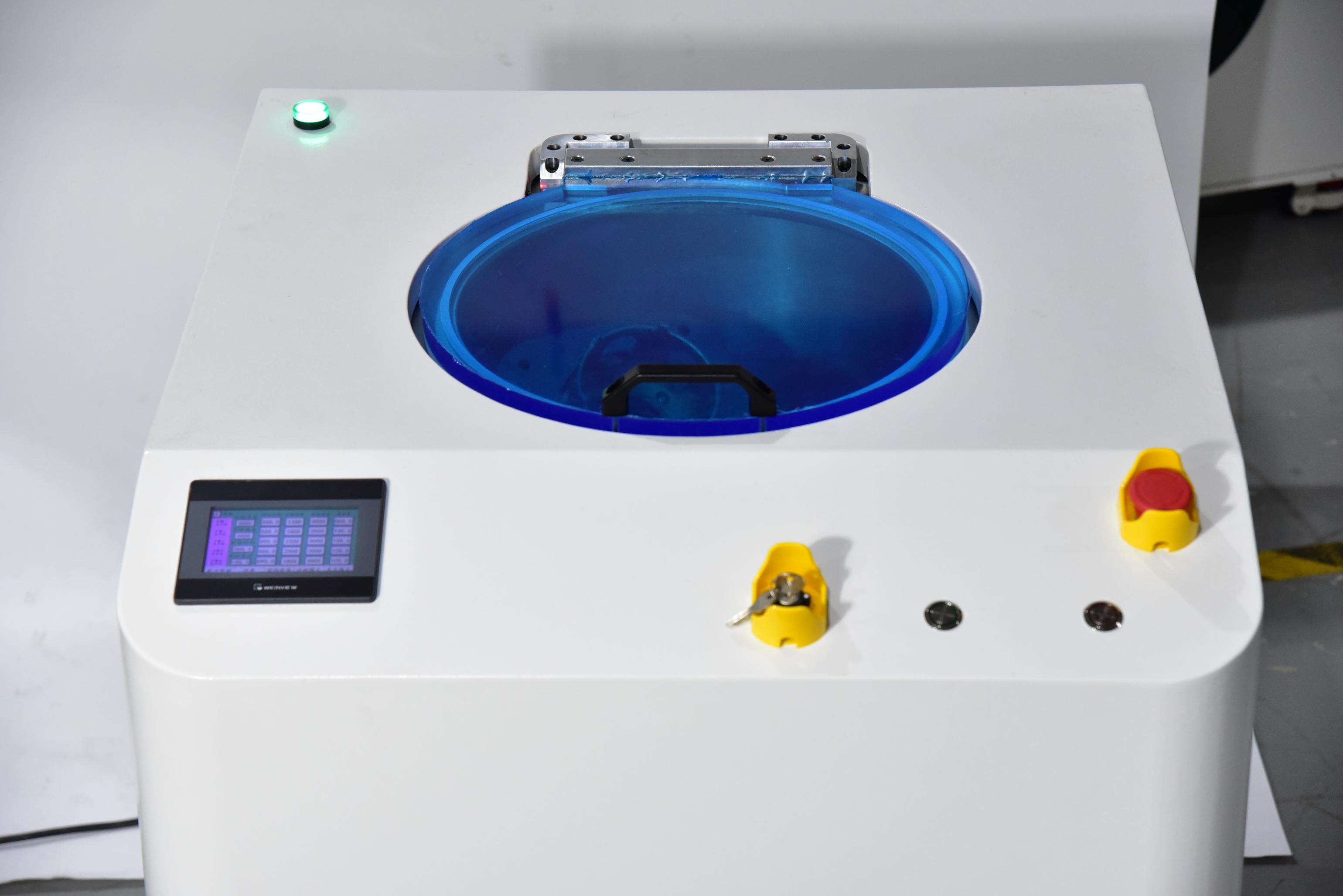

Large Capacity Vacuum Planetary Centrifugal Defoaming Commingler Mixer with Double Cup

Model Number:

BL-THA700(2000ml)Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab 5L Double Cup Vacuum Planetary Centrifugal Stirring And Deaeration Mixer MachineNext:

Top Quality Vacuum Planetary Centrifugal Stirring Mixing Mixer Optional Two 500ML Containers

Large Capacity Vacuum Planetary Centrifugal Defoaming Commingler Mixer with Double Cup

Product characteristics

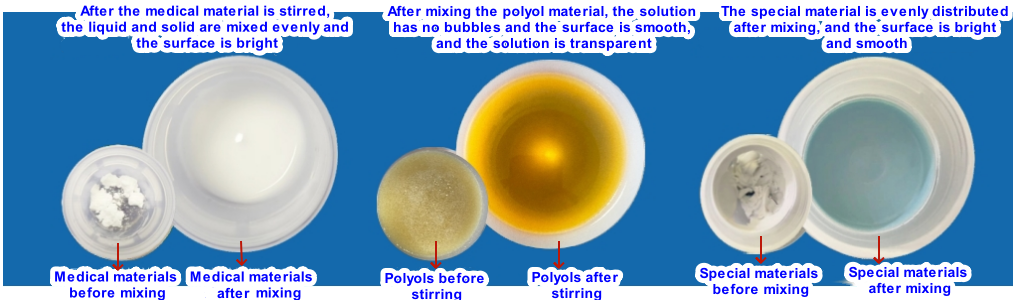

It can evenly stir a variety of materials in a short time, including high-viscosity materials, liquids, and even nanoscale powder materials, and can also stir materials with large mixing ratios or specific gravity differences. Mixing and defoaming at the same time with super strength and high speed.

Product application

Application field

LED package/display |

Adhesive |

Silicone rubber |

|

Polymer material |

Argentol |

Epoxy resin |

Medicine |

Printing ink |

Conductive adhesive |

LCD |

Subject |

Product performance

l Vacuum type, high configuration, experimental type, non-contact mixing

l Using German planetary stirring technology.

l At the same time of rotation/revolution, with a high-efficiency vacuum pump, the material is stirred evenly in tens of seconds to a few minutes, stirring and vacuuming are carried out simultaneously.

l The rotation speed of the revolution can be independently controlled, and it is designed for some materials that are very difficult to stir evenly.

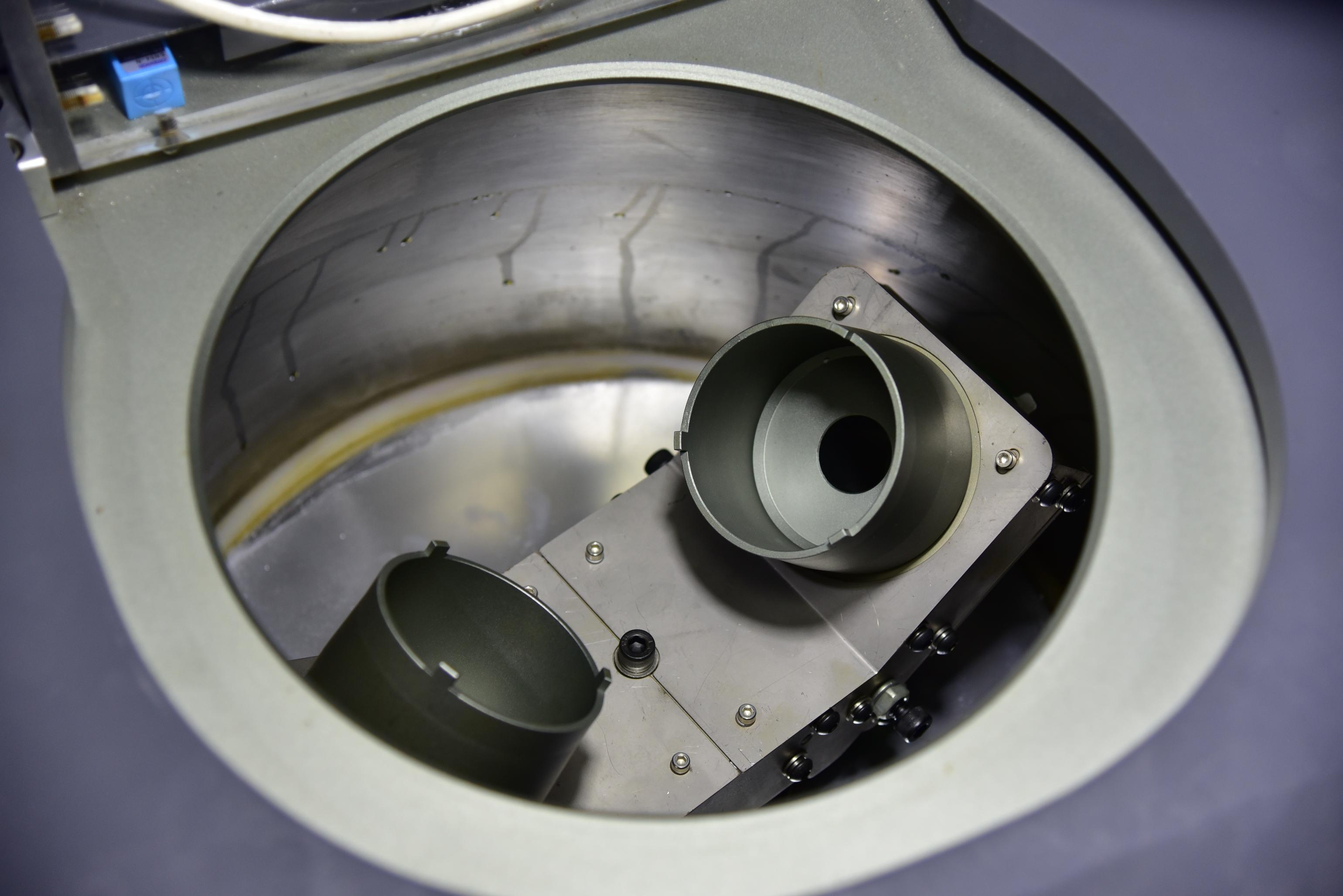

l Equipped with different switching fixtures, pins and cups, materials within a few grams to 2000 grams can be stirred, which can meet all requirements from test to mass production.

l It can store 20 sets of data (can be customized), and each set of data can be divided into 5 sections to set different parameters such as time, speed, vacuum degree, etc., which can cope with the stirring defoaming requirements of most materials.

l The maximum speed can reach 2500 revolutions per minute, and all kinds of high-viscosity materials can be evenly stirred in a short time.

l The key components are made of big brands in the industry to ensure the stability of long-term use of the machine with high load.

l Some functions of the machine can be customized according to customer requirements.

Technical parameter

Equipment type |

BL-THA700(2000ml) |

Maximum agitation |

2000ml,2*1000g |

Working mode |

Vacuum/rotation/revolution/non-contact |

Revolution speed |

200-2500rpm, accuracy 1rpm(asynchronous motor) |

Rotation speed |

Fixed specific speed, accuracy 1rpm(servo motor) |

Setting time |

0-300SX5(total 5 stages), accuracy 1S |

Continuous running time |

30mins |

Seal chamber |

One die molding |

Stored program |

Group 5 (Willenton touch screen) |

Vacuum degree |

100kPa to-100kPa |

Power supply |

AC220V,50Hz/60Hz,2.3KW |

Working environment |

10-35℃,35-80%RH |

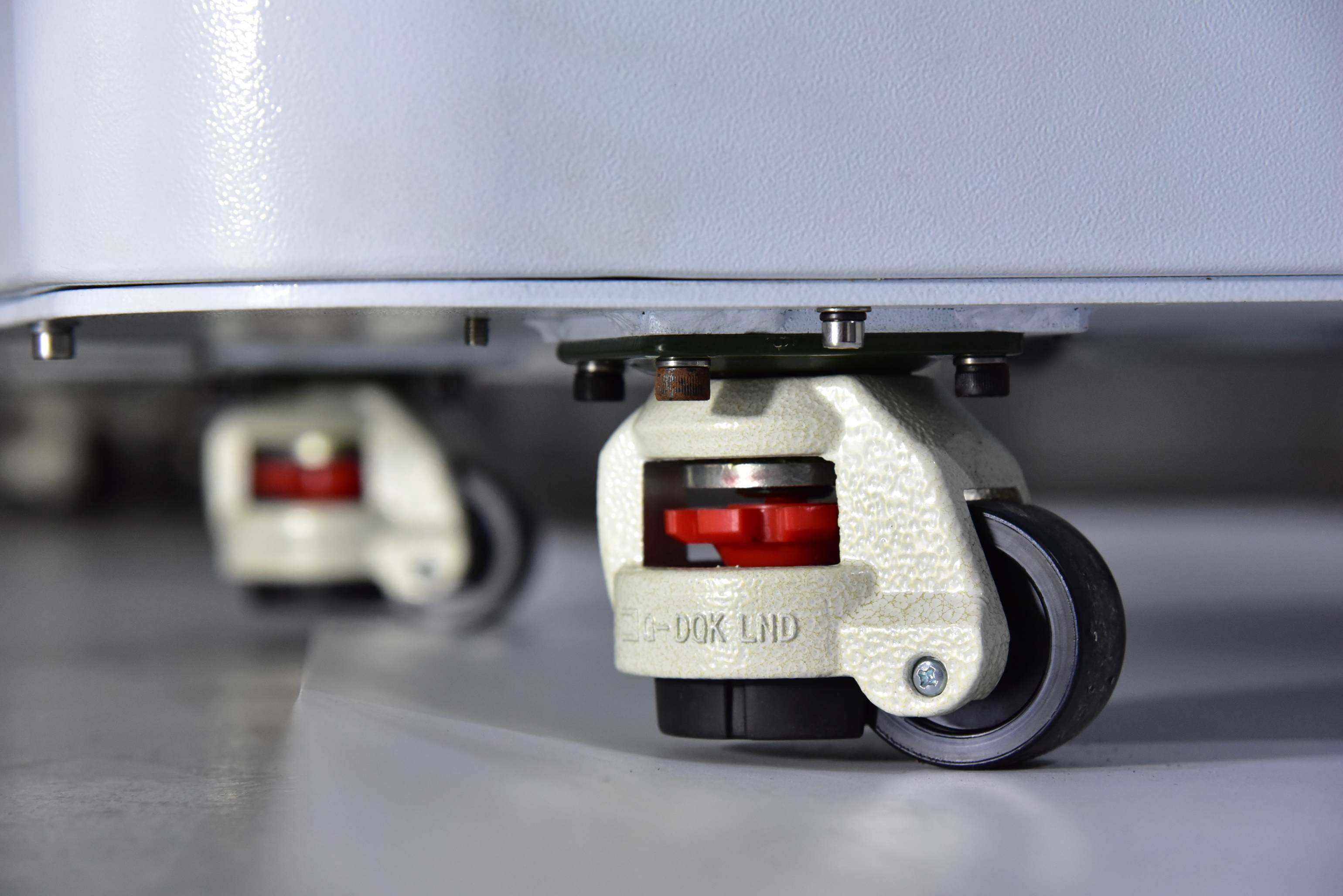

Overall dimension |

L800mm*W770mm*H870mm |

Main engine weight |

300kg |

Vacuum setting |

Independent switch/with delay control function/manual setting |

Self-check function |

Unbalance over limit automatic alarm reminder |

Security protection |

The equipment will stop automatically if it fails The equipment will automatically lock when it is running The equipment will stop immediately once the cover is opened |

Product details:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588