products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab 18650 26650 21700 4680 32650 AA AAA Cylindrical Cell Grooving Machine Beading Machine

Model Number:

TMAX-GC650Input Power:

140WNet Weight:

55KgCompliance:

CE CertifiedWarranty:

One year limited with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Electrode Sheet Baking Machine Three Layers Vacuum Drying Oven For Battery Making MachineNext:

18650 Desk-Top Capacitive Discharge Spot Welding Machine

Lab 18650 26650 21700 4680 32650 AA AAA Cylindrical Cell Grooving Machine Beading Machine

Ⅰ、Description:

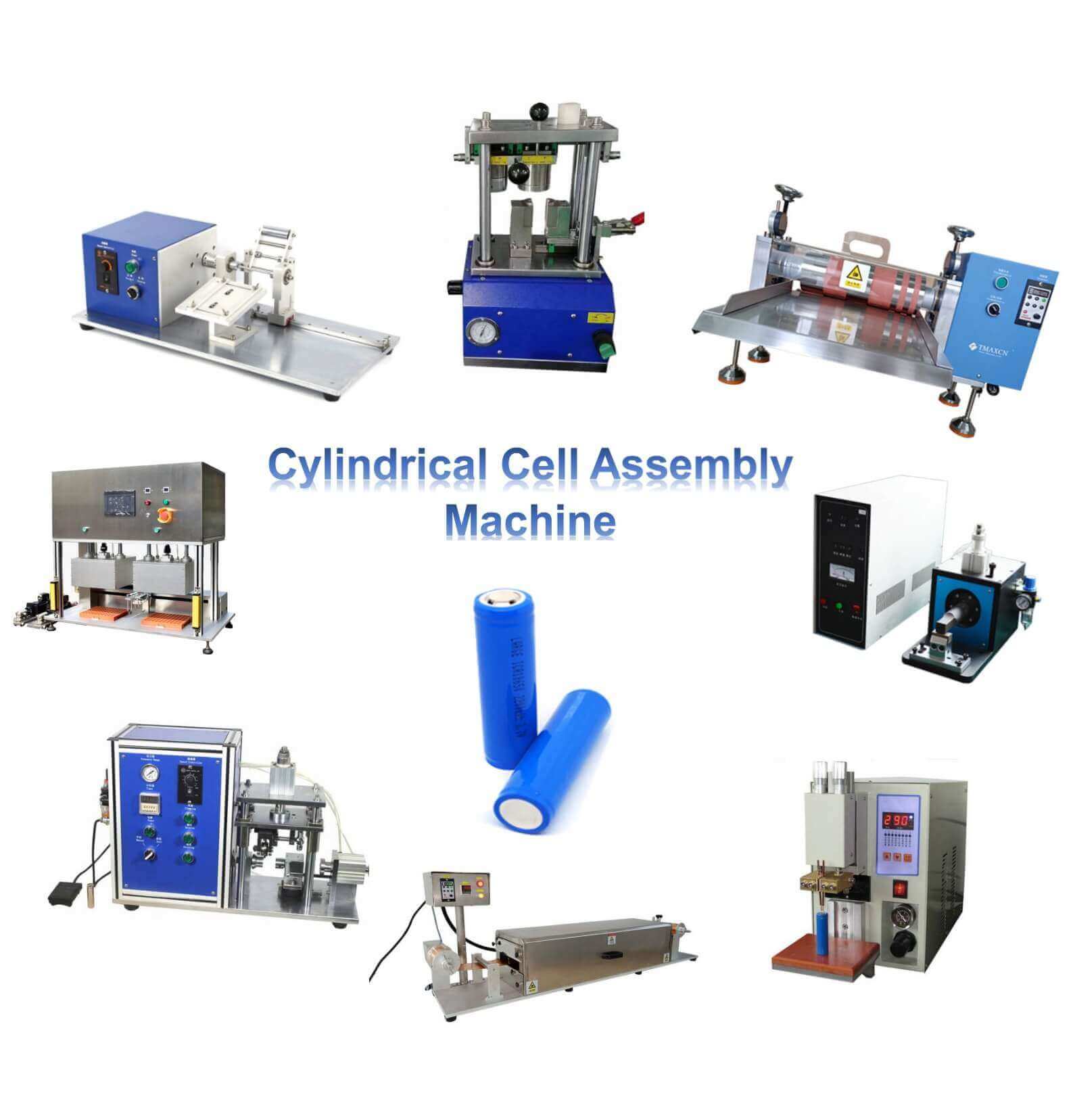

It is mainly used in the sample production of laboratory battery material research and development, shell rolling groove of cylindrical battery and cylindrical capacitor, and it can also be used in small batch trial production in the factory.

Ⅱ、Introduction:

TMAX-GC650

Series is a CE Certified semi-auto grooving machine. It is used for grooving

various cylindrical cell cases including CR123, 18650, 26650,2100, 32650 4680 and AA,

etc.

Each type

of cylinder cell can only be grooved specifically by certain model of this

equipment, please select the right grooving die for different cylinder cell.We provide a full ranges of Battery Pack Line.

Ⅲ、Main Features:

* The width of the groove is adjustable.

*The depth of groove is adjustable.

*Groove depth time can be set.

*The groove rolling speed is stepless speed regulation.

*Adopt manual and automatic groove rolling mode.

*Can process all kinds of cylindrical battery shell groove.

*The hob adopts precision machining to ensure the accuracy, reliability and stability of groove forming.

Ⅳ、Specification:

Model |

Grooving Machine TMAX-GC650 |

Source voltage |

110V-220V AC, 50/60Hz Single Phase |

Power |

140W |

Warranty |

One year limited and lifetime support |

Suitable battery model |

18650 / 26650 / 32650, can be customized |

Advantages |

1 Customized die for other cylindrical cell types is available according to request 2 Each type of cylinder cell can only be grooved specifically by certain model of this equipment. Please select the type of cylinder cellfor the corresponding grooving die of each cylinder cell type. |

Grooving depth |

1.2-2.0mm adjustable |

Grooving width |

1.1-1.5mm |

Grooving precision |

±0.1mm |

Knife life |

>100 0000times |

Air supply |

0.5-0.7MPa |

Dimension |

600*450*350mm |

Weight |

68kg |

Ⅴ、Product Display:

![]()

![]()

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588