products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

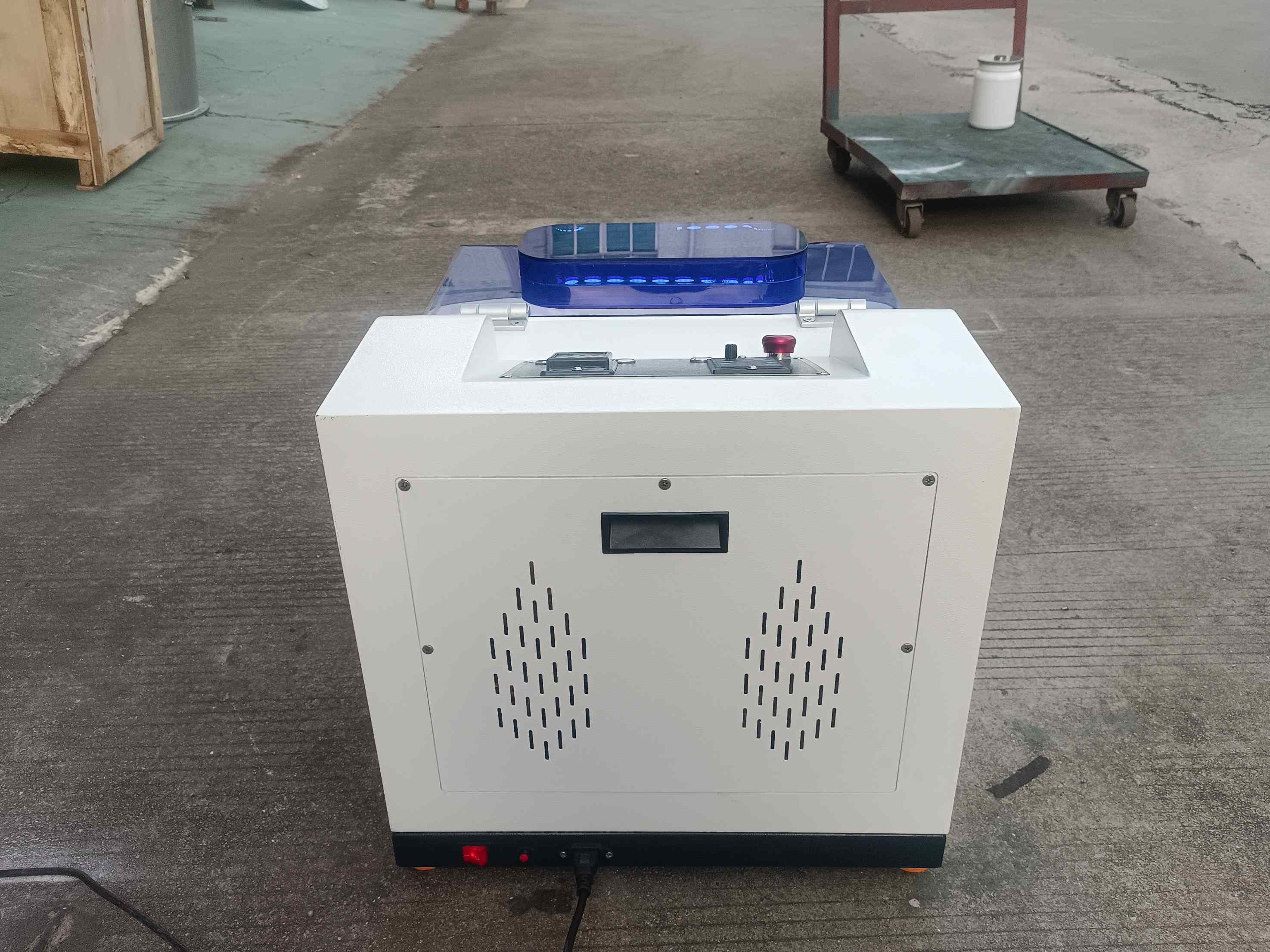

Lab Three-dimensional Cycloidal Oscillating Multi-sided Operation Mixer Device

Model Number:

TMAX-SWH-2Dimension(L*W*H):

L670*W560*H610mmNet Weight:

120KGCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Double Cup High Efficiency Planetary Gravity Agitator Defoaming MachineNext:

Lab Vacuum Centrifugal Stirring Mixer for Mixing And Defoaming High Viscosity Glues

Lab Three-dimensional Cycloidal Oscillating Multi-sided Operation Mixer Device

A. Use

Three-dimensional mixer formerly known as three-dimensional cycloidal mixer, also known as oscillating mixer, is currently the most advanced one of the powder, granular material mixing equipment, the machine is used in electronics (lithium cobalt oxide), ceramics, chemical, daily chemical pharmaceutical, food, light industry, electrical, machinery and various scientific research units of powder, granular material uniformity mixing.

B. Working principle

The mixing barrel of the machine can be multi-sided operation, the material has no centrifugal force, no specific gravity segregation and stratification, accumulation phenomenon, each component can have a wide weight ratio of mixing rate of more than 99.9%, and the maximum device coefficient can reach 0.9(p ordinary mixing machine is 0.4-0.6). Small footprint, for energy-saving and efficient mixing, the machine in operation due to multi-direction mixing, accelerate the flow and diffusion effect, to solve the general mixer due to centrifugal force generated by the material specific gravity segregation accumulation phenomenon, mixing without dead Angle, can effectively ensure the best quality of mixed materials.

C. Structural characteristics

The machine is composed of barrel body, frame, rotating wall, motor, decelerating device, etc., equipped with time relay to control the time, the rotating wall is made of high-quality stainless steel 304, the barrel body is polished, the replacement barrel body is less than 130mm in diameter/less than 190 in height, the flow effect is good when the material is mixed, no dead Angle, no pollution of the material, easy to operate. Easy to clean, smooth appearance, beautiful and generous.

D. Main technical parameters

Barrel body |

φ130mmX190mm height |

Reference overall dimension |

500x600x420mm(subject to actual objects) |

Weight |

60KG |

Power source |

Single-phase 220V,50HZ |

Protection |

Open cover stop protection, overload and overcurrent protection |

Motor specification |

150W |

Speed regulation |

Infinite digital display speed regulation |

Spindle speed |

0-87r/min |

Volume |

2L |

E. Related reference pictures

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588