products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab Semi-auto Prismatic Cell Stacker Stacking Machine For Battery Research

Model Number:

TMAX-PCSM200Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Laboratory 8000W, 20kHz Ultrasonic Metal Welding Machine For Battery Prismatic CellNext:

Laboratory Prismatic Cell Manual Steel Ball Sealing Machine

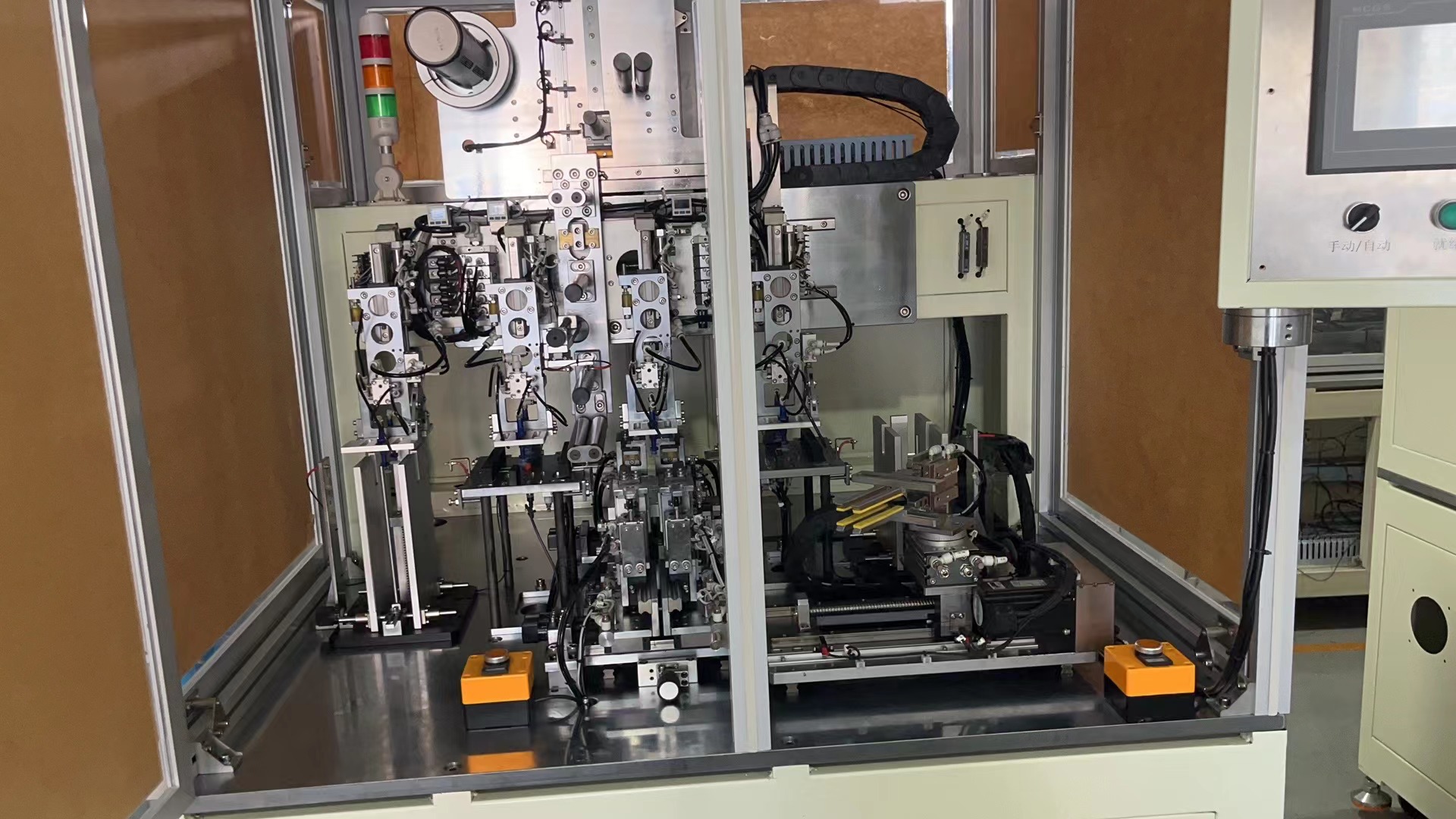

Lab Semi-auto Prismatic Cell Stacker Stacking Machine For Battery Research

1. Functional Overview

The equipment is primarily designed for assembling the positive and negative electrode sheets along with separator layers into a Z-fashion stacking configuration to construct the battery cell. The left and right material picking robotic arms retrieve the electrode sheets from the positive and negative material hoppers. Following precise secondary positioning on the positioning platform, they alternately place the sheets on the stacking platform. The stacking platform moves left and right in coordination with the two robotic arms' actions, with the separator forming a Z-fashion to isolate the positive and negative electrode sheets. This cyclical action by the equipment accomplishes the stacking assembly of the electrode stack.

2. Technical Parameters

Item |

Specification |

Dimensions |

1850mm(L)×1350mm(D)×1850mm(H); subject to design completion |

Power Supply |

220V 50Hz |

Air Source |

0.5MPa |

Environment |

Non-corrosive gases, liquids, explosive gases |

Color |

Supplier standard color sample(International Warm Gray 1C) |

Applicable Specifications |

Length L: 130-260mm Width W: 80-200mm Thickness H: 0-20mm Tab Length Q: ≤20mm |

Equipment Speed |

1.3-1.5 seconds per piece |

Alignment Accuracy |

Center deviation±0.3mm |

Incoming Material Requirements |

-Uniform coating of electrode sheets -Thickness error<0.005mm,no wrinkling or sticking -Length and width size error<±0.2mm,wave edge<1mm(does not affect positioning) -Tabs must be flat,without bends or folds -Separator must be uniformly rolled,width error<0.1mm,taper error<0.2mm -Tape must be uniformly rolled,with no significant taper,wrinkles,or warping |

Separator Unwinding Control |

Tension control during stacking to ensure minimal separator extension deformation |

Separator Alignment |

Ensures uniform unwinding,alignment accuracy±0.2mm |

Defect Identification |

Identifies missing sheets |

Operation Rate |

95%(faults caused by the machine only),Qualification Rate:98%(defects caused by the machine only) |

Easy Model Change |

Simple training required for operation |

3. Process Performance

1. Electrode Sheet Configuration:

- Both positive and negative electrode sheets are configured with material magazine.

- The electrode sheets in the working material box have a real-time floating structure.

2. Secondary Positioning Mechanism:

- A secondary positioning mechanism is provided for the positive and negative electrode sheets, ensuring precise positioning.

3. Sheet-Picking Mechanical Arm:

- Utilizes a high-speed linear servo module set for stable and reliable vacuum picking and placing of materials.

- Switches positions between the material box, secondary positioning platform, and stacking platform.

- Positive and negative electrode sheet-picking mechanical arms alternately place materials.

4. Separator Unwinding Mechanism:

- Uses precise semi-closed loop control with continuously adjustable working tension.

- Equipped with an alignment correction mechanism.

5. Stacking Platform Mechanism:

- Features a precise guiding mechanism allowing real-time adjustment according to the thickness of the stacked sheets, accommodating different cell thicknesses.

- Driven by a high-speed linear servo module set for high-speed, precise, and stable reciprocating movement between the positive and negative electrode sheets.

- Cylinder-driven pressing claw performs X-Y bidirectional composite movements to press and position electrode sheets and separators, achieving the Z-shaped stacking process for lithium battery cells.

6. Electrical Control System:

- Centered on a PLC program controller.

- Uses set times, pressure, and position sensors as control signals to drive motors, directional valves, cylinders, and other actuators, automatically switching to complete the workflow.

7. Human-Machine Interface:

- Facilitates interaction, allowing operation settings and the display and feedback of various machine information.

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588