products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

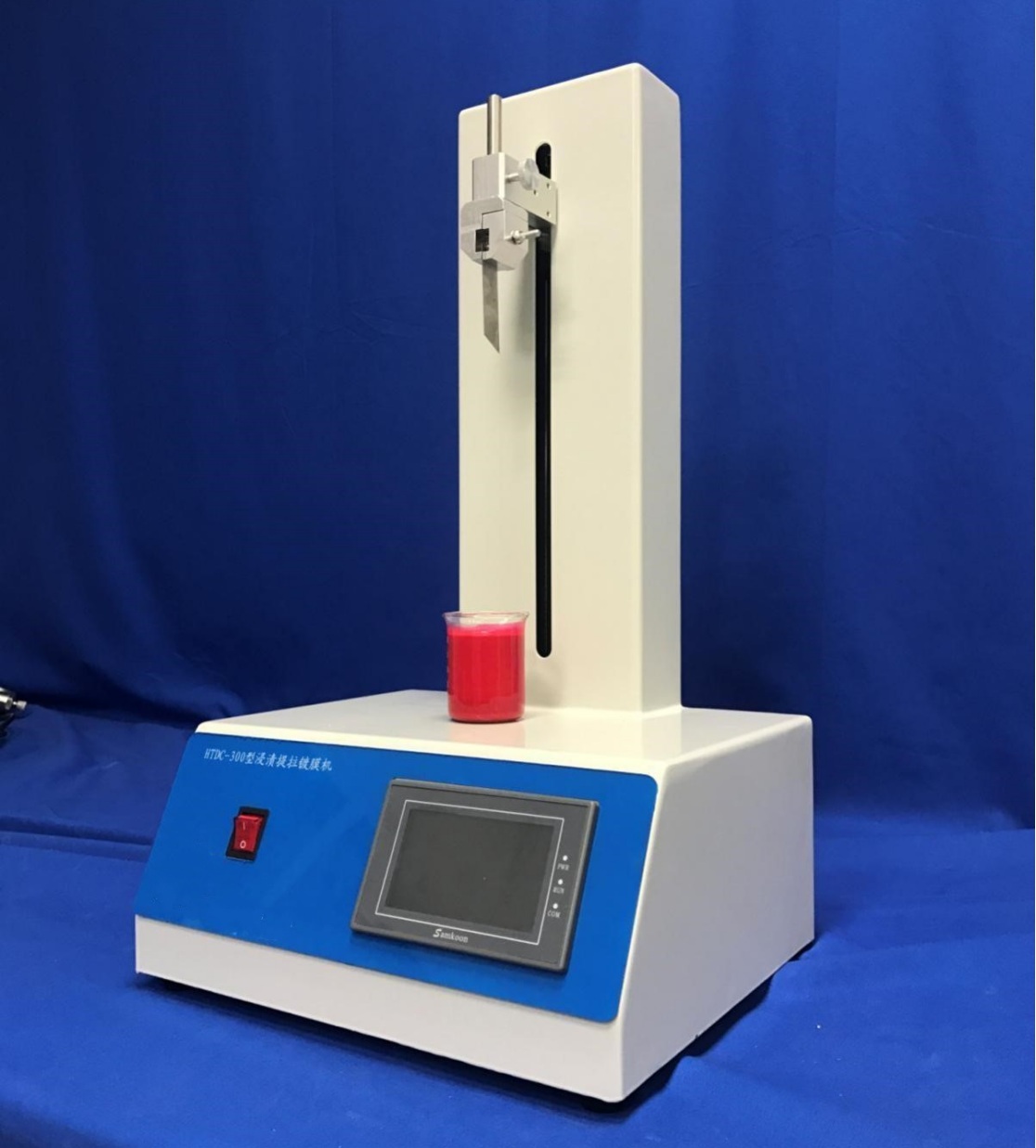

Lab High-end Single Station Dip Coater Suitable for Dipping And Pull Film Preparation

Model Number:

TMAX-HTDC-600Compliance:

CE CertifiedWarranty:

Two Years limited warranty with lifetime supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Multi-parameter Automatic Programmable Control Single Station Dip Coater with 4.3-inch LCD Touch ScreenNext:

Desktop Six-station Rotation Dip Coater for Precision Coating

Lab High-end Single Station Dip Coater Suitable for Dipping And Pull Film Preparation

HTDC-600 dip and lift coating machine introduction

HTDC-600 dip and pull coater is a high precision instrument suitable for dipping and pull film preparation by sol-gel method (SOL-GEL method, SG method for short). The core parts adopt imported parts, accurately control the lifting speed, and repeatedly coating without position deviation. Lifting speed, lifting height, impregnation time, number of cycle coatings, impregnation time, descending speed, residence time can be precisely controlled by the program. Applicable to glass, Si (100), Si (111), sapphire (Al₂ O₃), porcelain and resin substrate and other common substrates.

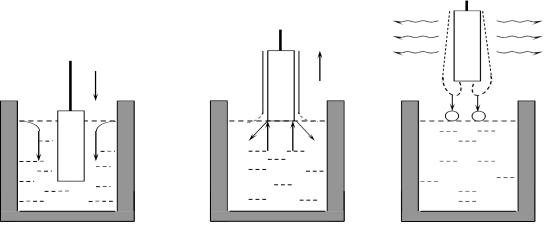

Introduction to dip pulling method

Dip and pull method is to soak the whole cleaned substrate into the pre-prepared sol, and then the substrate is smoothly pulled out of the sol at a precisely controlled uniform speed, and a uniform liquid film is formed on the surface of the substrate under the action of viscosity and gravity, by rapid evaporation of the solvent, so the sol attached to the surface of the substrate quickly gelates to form a layer of gel film. The process diagram is as follows:

There are many factors affecting the thickness of the film, including the viscosity, concentration, specific gravity, lifting speed and pulling Angle of the solution, the viscosity, specific gravity of the solvent, evaporation rate and the temperature and drying conditions of the environment.

HTDC-300 Dip Lift Coating machine Product features:

■ Adopt imported linear guide rail and servo motor to accurately control the uniform lifting speed.

■ Smooth operation without jitter, liquid level without vibration. Ensure the stability of the equipment and the uniformity of film formation.

■ Using the program control system independently developed by Huotong Instrument, lifting speed, lifting height, impregnation time, coating times, coating time, falling speed and falling height can be adjusted by program control

■ High-end brand touch screen, clear interface, easy to operate

■ Special design fixture, clamping more secure and firm

■ The whole machine is sprayed with plastic, the appearance is beautiful and generous.

HTDC-600 Dip and Lift coating machine product parameters:

1. Maximum stroke: 0-600mm

2. Lifting speed range: 1 ~ 9999 μm/s, minimum resolution 1 μm/s

3. Position accuracy: <0.01mm

4. Speed accuracy: ±0.01%

5. Impregnation time: 1 ~ 3600 s

6. Coating times: 1 ~ 1000 times

7. Coating interval: 1 ~ 3600 s

8. Power supply: AC 220V 50Hz

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588