products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab High Controllable Laser Cleaning Machine Equipped with A Pulse Fiber Laser

Model Number:

TMAX-CRCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Lab High Controllable Laser Cleaning Machine Equipped with A Pulse Fiber Laser

1. Basic information

Laser cleaning technology refers to the process of using high-power density laser beam to irradiate the surface of the workpiece, so that the dirt, rust spots or coatings on the surface evaporate or peel off instantly, so as to achieve cleaning and purification. Laser cleaning equipment is a new generation of high-tech products with green surface treatment

solution, which is easy to install, easy to operate and can realize automation production. It can be cleaned without chemical reagent, medium, dust and water by connecting the

power supply. It can remove the resin, paint, oil stain, stain, dirt, rust, coating, coating and oxide layer on the surface of the object.

It has the characteristics as below:

a. Non-contact cleaning will not damage the part matrix. No chemical cleaning solution, no consumables, safe and environmental protection.

b. The laser cleaning head is lightweight and can be held for a long time. The laser cleaning system is stable and almost maintenance free.

c. High cleaning efficiency and time saving. Red light assists in focusing, and the focusing position can be adjusted according to different field mirrors.

d. Precise cleaning, which can realize selective cleaning in precise position and size. Easy to operate just powered on. Optional for hand-held and automatic cleaning.

Comparison of different cleaning method:

Comparision |

Chemical cleaning |

Mechanical grinding |

Dry ice cleaning |

Ultrasonic cleaning |

Laser cleaning |

Cleaning method |

Chemical cleaning agent |

Mechanical / sandpaper contact |

Dry ice, non- contact |

Cleaning agent, contact |

Laser, non- contact |

Workpiece damage |

Have damage |

Have damage |

No damage |

No damage |

No damage |

Cleaning efficiency |

Low |

Low |

Middle |

Middle |

High |

Cleaning Result |

Normal, uneven |

Normal, uneven |

Excellent, uneven |

Excellent, Small cleaning range |

Excellent, High cleanliness |

Clean accuracy |

Uncontrollable, poor accuracy |

Uncontrollable, normal accuracy |

Uncontrollable, poor accuracy |

Can not specify range |

High controllable, high precision |

Consumables |

Chemical cleaning agent |

Sandpaper, grinding wheel, oil-stone |

Dry ice |

Special cleaning fluid |

Power only |

Safety and E protection |

Serious chemical pollution |

environmental pollution |

No pollution |

No pollution |

No pollution |

Operation |

High technical and protection |

High manpower and protection |

Simply, handheld or CNC |

Simple, but need manpower |

Simply, handheld or CNC |

Investment and using cost |

Low initial, extremely high consumables |

High initial, High manpower, High consumables. |

Middle initial, high consumables |

Low initial, Middle consumables |

High initial, no consumables |

2.Product Specification

2.1 CR Series Suitcase Type

Portable hand-held laser cleaning machine is a portable laser cleaning tool. It has many advantages, such as portability, light weight, flexible and adjustable parameters, wireless control, etc. It can effectively remove rust, stains, oil stains, coatings, etc. on the surface of workpieces.

It can be applied to mechanical processing, mold cleaning, food processing, electronic circuit, cultural relic repair, and other industries. With the characteristics of precise positioning, it can meet the processing of various shaped workpieces, to achieve highly efficient cleaning effect.

The cleaning machine is equipped with a cleaning type pulse fiber laser as the cleaning light source. The laser adopts a master oscillator power amplifier (MOPA) structure, in which the main oscillator uses a semiconductor laser as the seed source, and the power amplification is realized through a traveling wave fiber amplifier. This MOPA fiber laser has the characteristics of independently adjustable pulse width and frequency and can still maintain a high stable peak power output under the condition of changing the pulse width and frequency to adapt to a wider range of cleaning scenarios.

The hand-held laser head of the cleaning machine has a simple appearance and is small and light, which can be used for a long time. Integrated designed button and handle make operation simple and easy. The built-in scanning system adopts small high-speed motor and drive, and the main body is formed by integrated processing, which is solid, dust-proof, stable and durable. The laser head adopts the red-light auxiliary focusing design, which can easily find the focusing position under different field mirrors by using the red-light indication, meeting the auxiliary focusing requirements under different scenes.

The control system adopts the laser cleaning control card and program, which can simultaneously control the laser parameters and scanning system parameters and is equipped with a hand-held wireless control card. The control card is connected with the cleaning machine through wireless mode, which can realize remote control of scanning shape, scanning length, laser output power, frequency, pulse width and other parameters. The power interface is a standard three plug 220V AC power supply, plug in and then ready for cleaning tasks.

The figure shows the physical picture of handheld laser cleaning machine (the specific appearance is subject to the actual delivery):

2.2 Product Features

It can be operated offline, Start cleaning after power on. Extremely light laser cleaning head, easy for long time handling.

Red light assisted focusing technology, can adjust the focusing position according to different field mirrors.

Wireless control can make parameter setting and light output control remotely, and parameters can be updated at any time.

Portable trolley case design, with an overall weight of 28kg, which can be carried as luggage by high-speed railway and air consignment.

Super integrated injection molding case, cushion design, stable structure, wear-resistant, shockproof and fall resistant.

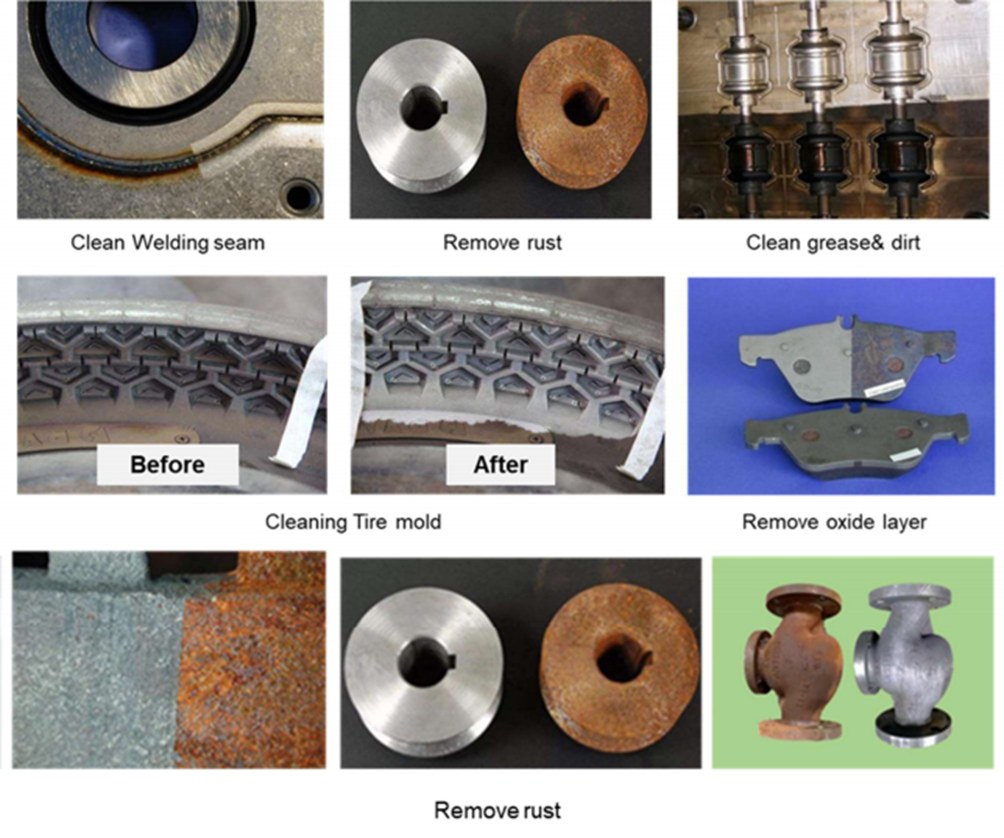

2.3 Application samples

2.4 Technical Parameters

Operating Environment |

|

|

CR series |

Power Supply |

Standard AC220V±10%, monophase, 50/60Hz |

Total consumption |

≤450W |

Working temperature |

0ºC~40ºC |

Storage temperature |

-10ºC~60ºC |

|

≤80% |

Optical Parameters |

|

|

≤100W |

Power instability |

<2% |

Laser Working Mode |

Pulse |

|

10-500ns |

Maximum mono-pulse energy |

1.5mJ |

Power regulation range(%) |

10-100( Gradient adjustable) |

Repeat frequency(kHz) |

1-3000(Gradient adjustable) |

|

Yes |

Fiber length |

5m |

|

Air cooling |

Cleaning Head Parameters |

|

Scan width |

20-130mm, supporting 8 scanning modes |

Scan Speed |

6000mm/S |

Clean efficiency |

0.2-0.5 m3/min |

Scanning frequency |

10Hz~300Hz |

|

160mm (Optional 210mm/254mm/330mm/420mm) |

Spot Size |

≤10 mm |

Mechanical Parameters |

|

|

620*469*292 mm |

Packing dimensions |

890*600*470 mm |

Machine Weight |

26 Kg |

|

44 Kg |

Cleaning head weight |

<0.75kg |

|

Handheld/CNC |

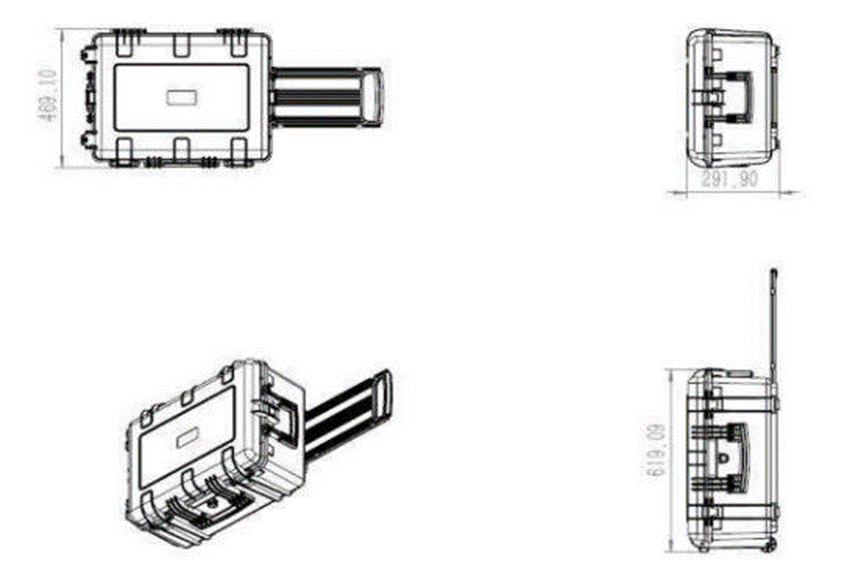

2.5 Overall dimensions

Dimension

Cleaning Head Dimension

3.Consumables used in machine

Here are the consumables used in machine:

S.N. |

Item |

Unit |

MOQ |

Origin |

1 |

Protective lens |

Piece |

5 |

China |

2 |

Focus Lens |

Piece |

1 |

China |

3 |

Goggles |

Pair |

1 |

China |

4.Technical Training and After Sales Service

We will provide necessary manual and training videos together with the machine to train buyer how to operate this machine.

We will provide our customer with on-line expert guidance and on-line supports.

5.After sales service

Warranty:24 months for laser source, excluding glass fiber cable, charges and warranty scopes are subject to laser source supplier’s warranty terms.12 months from the date of delivery for main machine, excluding lens and other consumables. Within warranty period, the seller shall offer spare parts with free of charge (excluding the case of force of majeure, such as natural disaster and war, incorrect operation and sabotage. All the cost incurred by spare parts replacement shall be borne by the buyer, including freight cost and customs.

After the warranty, we will also provide favorable service of long-term technical supports and spare parts supply to ensure machine's stable and continuous running.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588