products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab Electric Lifting And Stirring Mill Optional Tank Material for Numerical Simulation and Fabrication of Perovskite Solar Cells

Model Number:

TMAX-MBMCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab 150ml And 300ml Vacuum Mixing Defoaming Machine Used in Synthesis And Fabrication of PerovskiteNext:

Perovskite Solar Cell Lab Plant Single Station Stainless Steel Vacuum Glove Box

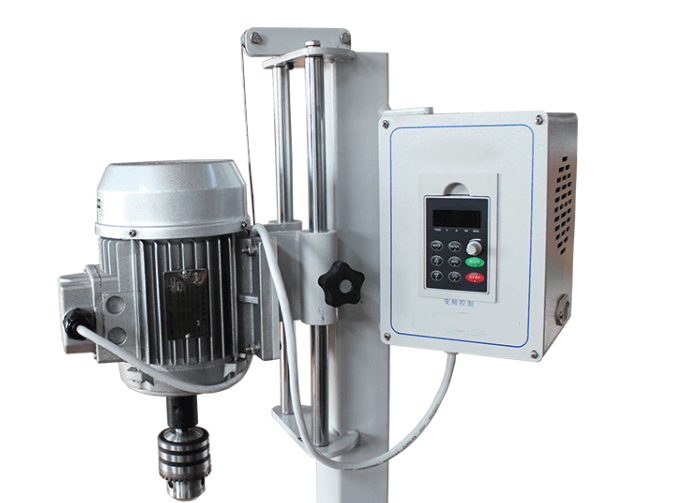

Lab Electric Lifting And Stirring Mill Optional Tank Material for Numerical Simulation and Fabrication of Perovskite Solar Cells

Working Principle:

The spindle driven the agitator do high speed rotating, make the grinding medium to do irregular movement.

The grinding medium would be collided, extruded, friction and sheared because of the disorderly movement,

so pulverized, finely grounded the material. Further, if the size, shape and ratio of the grinding media is different,

the grinding effect would also different . Under normal circumstances, the greater the specifications of the grinding medium,

the more coarse material crushing; Conversely, the smaller the grinding media, the finer the grinding materials. The abrasive

effective would be better with appropriate ratio of different grinding media’s specifications, coupled with the appropriately

adjusting for speed.

Product Features:

1.High energy utilization, and can get a very high power density, so saving energy;

2.Product size is easy to be adjusted,ensure the final degree of fineness by adjusting the residence time of material in the barrel;

3.Small vibration, low noise;

4.Simple structure, easy to operate;

5.It can achieve various of process parameters requirement, product continuously or intermittently according to the need;

6. It can be well controlled grinding temperature because the milling cylinder has a jacket;

7. Can produce devices with a variety of special features according to the need, such as: the timer, speed control mode, circulation method, temperature regulator etc;

8. Can select grinding cylinder with different materials (stainless steel, corundum ceramics, polyurethanes, zirconium, etc.) and stirring device.

The electric lifting and stirring ball mill is mainly composed of a stationary grinding cylinder filled with small diameter grinding medium, a stirring device and other auxiliary devices (such as circulation device, cooling device, timing, speed control, etc.), with high grinding efficiency and small grinding particle size, which can well meet the requirements of various process parameters, simulate various indicators in production, and at the same time, because of its small batch, low power consumption and low price Its advantages are that school, research unit and company are the first choice equipment for grinding technology, new materials and coating research. It is widely used in the production of zirconium silicate, zirconium, alumina, ceramics, chemical industry, electronic materials, magnetic materials, paper-making, coatings, non-metallic minerals, new materials, paints, graphite, calcium carbonate, pharmaceutical and other ultra-fine powders. We are committed to providing premium laboratory mixer for you!

Specification

Experimental mini type |

Experimental light type |

Production configuration |

|

Volume (L) |

0.5~3 |

5~20 |

30~500 |

Jar Material |

Stainless steel, ceramic,corundum, zirconia,polyurethane etc. |

Stainless steel, ceramic,corundum, zirconia,polyurethane etc. |

Stainless steel, ceramic,corundum, zirconia,polyurethane etc. |

Feed size |

Less than 5mm |

Less than 20mm |

Less than 20mm |

Discharging size |

Less than 1um |

Less than 1um |

Less than 1um |

Rotate speed (r/min) |

1400,2800 and adjustable |

50~500 |

50~500 |

Speed adjustment mode |

Electronic speed control |

Fixed speed or frequency control |

Fixed speed or frequency control |

Power |

120~550W |

1000~5500W |

1000~7500W |

Applications

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588