products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

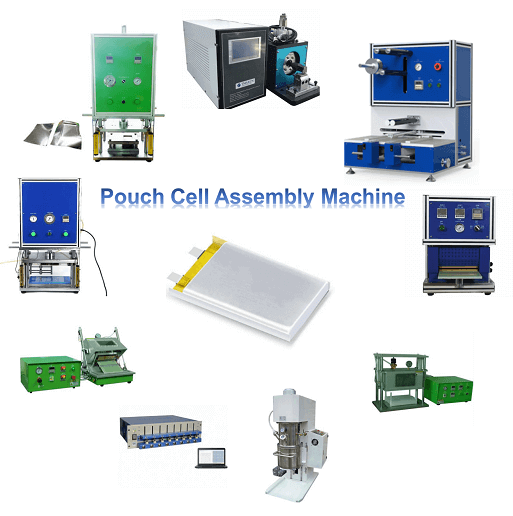

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

High Speed Slitting Machine for Metal Foil, Plastic Film Cutting

Model Number:

TMAX-1300FCompliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Copper/Steel Mesh Plastic Tape Insulation Sleeve Cutting machineNext:

Double Servo High Speed Automatic Die Cutting Machine for Pouch Cell

High Speed Slitting Machine for Metal Foil, Plastic Film Cutting

It is suitable for slitting various rolls of plastic film (PVC, OPP, PET, CPP), paper, glass fiber, aluminum foil paper, aluminum foil, stickers, non-woven fabrics, etc. Cutting and rewinding of other coils.

Features

1. The whole machine is controlled by Mitsubishi PLC and Weinview touch screen, and the screen can set working parameters and display the operating status.

2. The host machine adopts 3 sets of Yaskawa imported inverters and servo motors to control the linkage, with high speed and stable tension.

3.Automatic hydraulic loading, saving time and effort. The load can bear 1500KG.

4. Pneumatic material pressing and splicing platform is adopted to save material changing time.

5. Use independent servo correction control system to correct material deviation.

6. The machine is equipped with SMC proportional valve and top solid pressure reducing valve, which can adjust the tightness of the rewinding material during the automatic tension of the slip shaft.

7. All transmission shafts adopt dynamic / static balance processing to ensure the stability and accuracy of the material transfer and slitting process.

8. Automatic meter counting device with roller encoder. When the material is slit and rewinded to a preset length, the machine will automatically stop working.

9. Adopting a 3-inch air-swelling shaft winding type to collect left and right waste materials (receiving by the cable machine)

10. The wall plates and accessories of the machine are customized with CNC technology to ensure the stability and cutting accuracy of the machine.

Specifications

Maximum unwinding width |

1300mm |

Maximum unwinding diameter |

1000mm |

Maximum winding diameter |

Double-axis staggered winding: 600mm Single-axis winding: 1000mm |

Cutting width |

20-1300mm |

Slitting speed |

0-300 m / min |

Tension range |

Constant tension, controllable |

Inner diameter of paper tube |

3 inches |

Slitting accuracy |

±0.5mm |

Voltage |

380V 3 phase |

Total power |

16KW |

Machine size |

3100*2700*1550mm |

Machine weight |

2500kg |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588