products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

High Precision Solid Electrolyte Testing Tester Machine for Battery R&D

Model Number:

TMAX-SEMSCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

High Precision Solid Electrolyte Testing Tester Machine for Battery R&D

The Importance of Electrochemical Performance of Solid Electrolyte

Driven by the rapid development of the lithium-ion battery (LIB) industry, improving the energy density and safety of the battery is an important research direction of for the LIB researchers. All-solid state battery is considered to be the most promising secondary battery with high safety and high specific energy in the future. Solid electrolyte (SE) is the most important core component, and the most important performance indicators used to judge the performance of solid electrolyte are ionic conductivity,Li-metal interface stability and full cell performance. On the one hand, the density, roughness and integrity of the pressed solid electrolyte sheet determine the conductivity of the solid electrolyte and the cycle performance of the full cell.; On the other hand, the accuracy of the test results can only be guaranteed by the stable and uniform stress application and the accurate thickness measurement during the experiments. Therefore, the production and testing system that can exert stable and standardized pressure plays a key role in the development of solid electrolyte and lithium metal battery

Limitations of Traditional Production and Traditional Testing

Traditional tableting

The traditional process generally uses a manual tablet press to press the solid electrolyte powder. The force of traditional manual method is uneven and cannot reach a high pressure, which will cause the thickness of SE sheet asymmetry with relatively low density, and finally trigger the depression, edge falling and fragmentation, etc., of the SE sheet after demoulding. Moreover, the traditional method need take a lot of time for the applying and releasing pressure, which seriously affects the experimental process and research efficiency

Traditional test procedure:

The traditional test method just simply holds the ceramic chip to measure the electrochemical properties. Because the force of the traditional test method is uneven, the maximum of the applied force is also limited, and the applied pressure cannot be quantified and maintained at a fixed value, the compression condition will exist great differences for samples with different thickness, area and roughness. Thus the experimental conditions cannot be normalized and standardized, and the measurement results will have poor consistency and low reproducibility.

Condition exploration:

Traditional clamps or fixture cannot provide uniform, stable and variable pressure for the preparation of solid electrolyte sheets or the exploration of test conditions.

Measurement mode:

Only constant pressure, non-quantifiable pressure, small pressure range, and unstable compression condition during the test.

Accurate Test Method for Solid Electrolyte by TMAX

For the testing method of the ionic conductivity of the solid electrolyte, we refer to the T/SPSTS 019-2021 standard, and combine with ther the testing method of the ionic conductivity of the solid electrolyte, we refer to the T/SPSTS 019-2021 standard, and combine with the general test process in the industry, including the standardization of sample preparation, fixture design, test device, and test conditions:

Sample preparation:

Oxide materials must be subject to high-temperature crystallization treatment (generally above 900 ℃) to ensure good ion transport performance. Generally, the density of electrolyte sheet is>95%, and the thickness is>500 μm; In terms of electrode preparation, the electrode must be polished with sandpaper with more than 3000 meshes and sprayed with conductive gold of a certain thickness (>5 μm) , after which the good interface contact can be ensured. Grind the edge of the metal with sandpaper to prevent short circuit. Use a multimeter to ensure the electronic continuity between any two points on the surface.

The sulfide materials can directly be tested by cold compression process. During the test, a certain pressure (usually >200 MPa) must be guaranteed to ensure good ion transport performance.

Fixture design:

A flat and compact contact surface, and a stable and uniform force application structure (quantifiable pressure) are required..

Test device:

An electrochemical workstation system capable of measuring high frequency impedance (>1MHz) is required. A short lead with good signal shielding is also required

Test conditions:

Select appropriate temperature and humidity, quantization pressure, frequency range and amplitude voltage.

For the electrochemical performance of solid lithium battery (charge-discharge cycle, electrochemical window), we combine the general test process in the industry, including the sample preparation, fixture design, test device, and standardization of test parameters:

Electrolyte preparation:

Oxide materials must be subject to high-temperature crystallization treatment (generally above 900 ℃) to ensure good ion transport performance. Generally, the density of electrolyte sheet is>95%, and the thickness is>500 μm. It must be with strictly polished by the sandpapers.

During the direct cold pressure test of sulfide materials, a certain pressure (usually>200MPa) must be guaranteed to have good ion transport performance.

Electrode preparation:

The positive electrodes shall be prepared by scraping, screen printing, sputtering deposition and other methods. The negative electrodes shall be prepared by surface treatment, melting, physical/chemical deposition, pressing and other methods to ensure good interface contact.

Fixture design:

It needs a flat and compact contact surface, and a stable and uniform force application structure (quantifiable pressure).

Test conditions:

Appropriate temperature and humidity, certain quantitative pressure, and strict sealing device

Solid Electrolyte Test Equipment

Solid electrolyte test system SEMS (IEST) is a multifunctional test system dedicated to solid electrolyte samples. It is a fully automatic measuring device for the electrochemical performance of solid electrolyte that integrates tableting, testing and calculation. The system adopts integrated design, including pressurization module, electrochemical test module, compaction density measurement module, and clamp, etc., which is applicable to the test of various oxides, sulfides, polymers and other kinds of electrolytes.

Scheme 1: high-precision automatic test system, model SEMS1100

Equipment parameters |

|

Pressure measurement accuracy |

0.05-5T |

Pressure measuring range |

±0.3%F.S |

Thickness test range |

0-8mm |

Thickness test resolution |

0.5um |

Thickness test accuracy |

±10um |

Sample mould diameter |

13mm, customized |

Temperature and humidity range |

0-50C/20%-90%RH |

Temperature and humidity accuracy |

±2C/±5%RH |

Installation requirements |

|

Power supply |

220-240V/50-60Hz |

Voltage variation tolerance |

±10% |

Power consumption |

300W |

Ambient temperature |

25±5C |

Ambient relative humidity |

≤80%RH(no condensation) |

Ambient magnetic field |

Keep away from strong electromagnetic fields |

Scheme 2: simple manual test device, model SEMS1000 (applied to electrochemical test)

Parameters

Pressure measurement accuracy |

10-400kg |

Pressure measuring range |

±0.3%F.S |

Thickness test range |

0-8mm |

Thickness test resolution |

5um |

Thickness test accuracy |

±10um |

Sample mould diameter |

13mm, customized |

Temperature and humidity range |

0-50C/20%-90%RH |

Scheme III: simple manual test device, model SEMS1300 (applied to ionic conductivity test)

Parameters

Pressure measurement accuracy |

50-2000kg |

Pressure measuring range |

±0.3%F.S |

Thickness test range |

0-8mm |

Thickness test resolution |

5um |

Thickness test accuracy |

±10um |

Sample mould diameter |

13mm, customized |

Temperature and humidity range |

0-50C/20%-90%RH |

Application

1. Powder production

The equipment can be used to tablet the powder samples under different pressure conditions, and the tablets obtained by SEMS are intact and free of cracks.

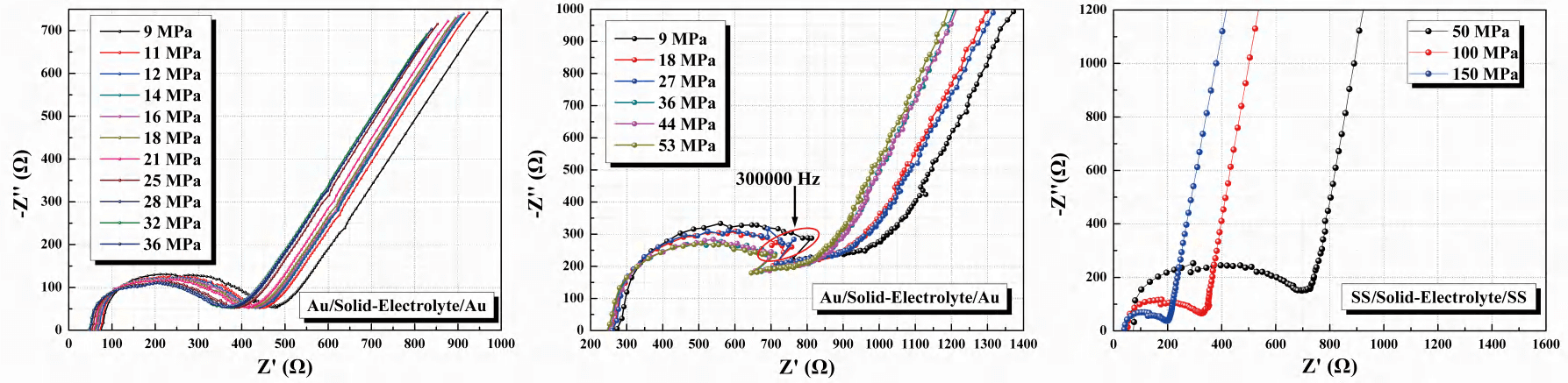

2. Ionic conductivity

Through the electrochemical impedance spectroscopy (EIS) module of SEMS, the ionic conductivity of solid electrolyte under different pressures can be obtained automatically

3. Electronic conductivity&compaction density

Through the DC polarization (DP) module of SEMS, the electronic conductivity and compaction density of solid electrolyte under different pressures can be obtained automatically.

4. Solid state battery cycle performance

Through the charge-discharge test (CD) module of SEMS, the cycle performance of solid lithium metal battery under different pressure and different electrochemical parameters can be analyzed.

5. Electrochemical stability window

Through the cyclic voltammetry (CV) module of SEMS, it is possible to analyze the electrochemical stability window of solid electrolyte under different pressure.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588