products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

High Precision Laser Welder for Prismatic Battery Welding 1500W/2000W/3000W/4000W/6000W

Model Number:

TMAX-ZW-J860Compliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

6000W Laser Welding Machine for Aluminum and Copper Sheets WeldingNext:

3000W Lifepo4 Prismatic Battery Laser Welder with Precision Control

High Precision Laser Welder for Prismatic Battery Welding 1500W/2000W/3000W/4000W/6000W

I.Equipment adaptation range

Copper, aluminum, iron, nickel, or their alloy metal welding, especially suitable for the welding process of aluminum bars or nickel to nickel connections in Prismatic batteries.

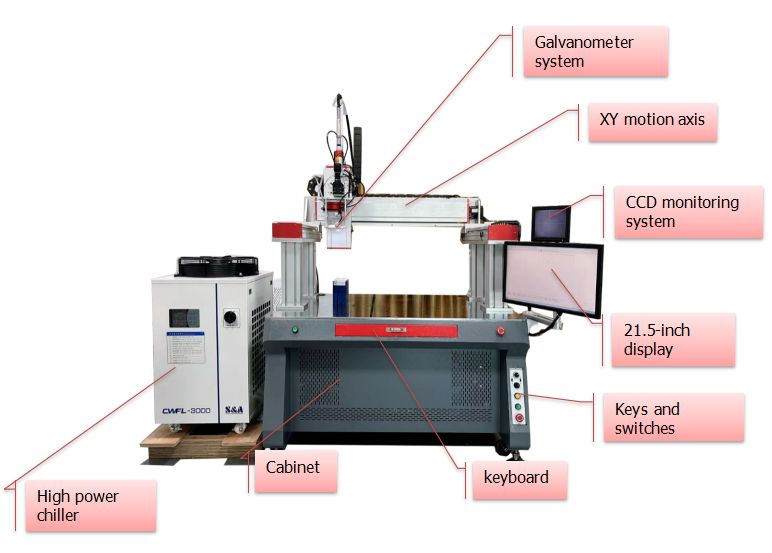

II.Equipment Overview

The TMAX-ZW-J860 gantry continuous galvanometer laser welding machine adopts internationally advanced fiber laser as the laser source, combined with our company's independently developed, designed, and manufactured gantry machine tool, which has good rigidity and stability; Operated with precision guide rail transmission, equipped with high response servo motors, high precision and fast speed; Mainly aimed at the welding of aluminum copper bar connectors for prismatic cell lithium battery PACK groups, as well as the welding of other hardware connectors.

III.Functional characteristics

● Paired with high-power fiber continuous laser, it has sufficient power, fast speed, high accuracy, and stable welding quality.

● It can support up to 6-axis motion control, adapt to automation needs in various occasions, and can be connected to automatic lines or operated independently.

● Equipped with a high-power galvanometer welding head, it can be used in conjunction with the XY gantry motion platform to facilitate the welding of various complex graphic trajectories.

● Specialized welding control software, welding process experts, comprehensive data saving and calling functions, with powerful drawing and editing graphic functions.

● Equipped with a CCD monitoring system, it is easy to debug and can monitor welding quality in real time.

● Equipped with a red light positioning system, it can quickly locate the welding position and focal length of the product, which is simple, convenient, and easy to use.

● A powerful water cooling circulation system can keep the laser welding machine in a constant temperature state, improve welding quality, and extend the machine's service life.

IV.Equipment structure

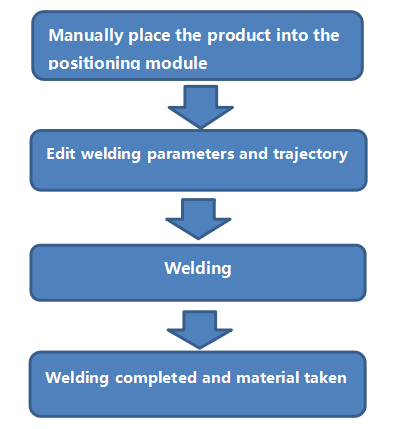

V.Workflow

VI.Technical Parameter

Specification and model |

1500W |

2000W |

3000W |

4000W |

6000W |

|||

Laser output power |

1500W |

2000W |

3000W |

4000W |

6000W |

|||

Power of galvanometer welding head |

1500W |

2000W |

3000W |

4000W |

6000W |

|||

CCD |

1.3 million images, anti flash |

|||||||

Wind knife |

Single layer wind knife |

Double layer wind knife |

||||||

Chiller |

1.5P |

2P |

3P |

4P |

6P |

|||

X stroke |

800mm |

1000mm |

||||||

Y stroke |

600mm |

800mm |

||||||

Z stroke |

400mm |

400mm |

||||||

Repetitive positioning accuracy |

±0.02mm |

|||||||

Fiber optic cable length |

10m |

15m |

20m |

|||||

Laser wavelength |

1070nm |

|||||||

Output method |

QBH |

|||||||

Cooling method |

water-cooling |

|||||||

electrical machinery |

400W servo motor |

|||||||

working voltage |

AC220V 50/60Hz |

AC380V 50/60Hz |

||||||

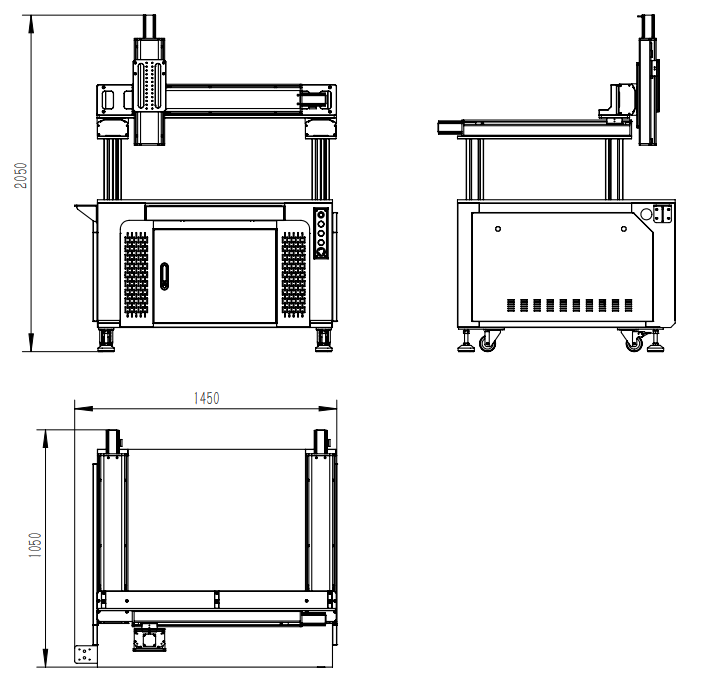

Reference dimensions |

L*W*H=1450*1050*2050mm |

L*W*H=1700*1280*2050mm |

||||||

Overall weight |

350KG |

450KG |

||||||

VII.External dimension diagram

VIII.List of Key Components

Key component names |

Brand |

Place of origin |

laser |

Chuangxin |

China |

Galvanometer system |

Zhibo Tech |

China |

Water-cooled chassis |

Special domain |

China |

control system |

TMAX |

China |

servo motor |

Xinjie |

China |

drive |

Xinjie |

China |

display |

Philips 21.5 inches |

China |

Industrial computer |

Jianuo |

China |

solenoid valve |

stars |

China |

cylinder |

stars |

China |

Photoelectric sensor |

Omron, Huayifeng |

Japan/China |

Lead screw |

TBI |

Taiwan |

Guide rail |

Jieyin |

Taiwan |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588