products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

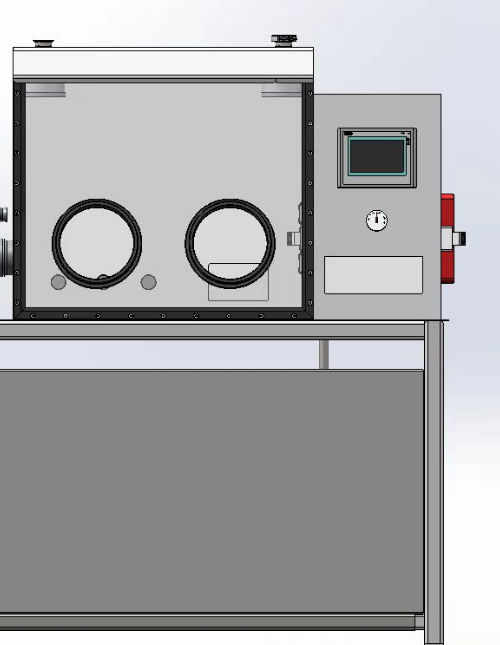

Desktop Single Side Single Station Glove Box with Water and Oxygen Monitoring System

Model Number:

TMAX-Lab800Compliance:

CE CertifiedWarranty:

One year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Three Glove Ports Single Side Glove Box with Purification System and Cryogenic Cold TrapNext:

Lab Water and Oxygen Circulation Purification Glovebox with Vacuum System

Desktop Single Side Single Station Glove Box with Water and Oxygen Monitoring System

Composition of the equipment

The equipment mainly consists of a closed box, a set of transition chamber, a set of circulation system (including purification and regeneration system), a set of water and oxygen monitoring system, and a set of control system.

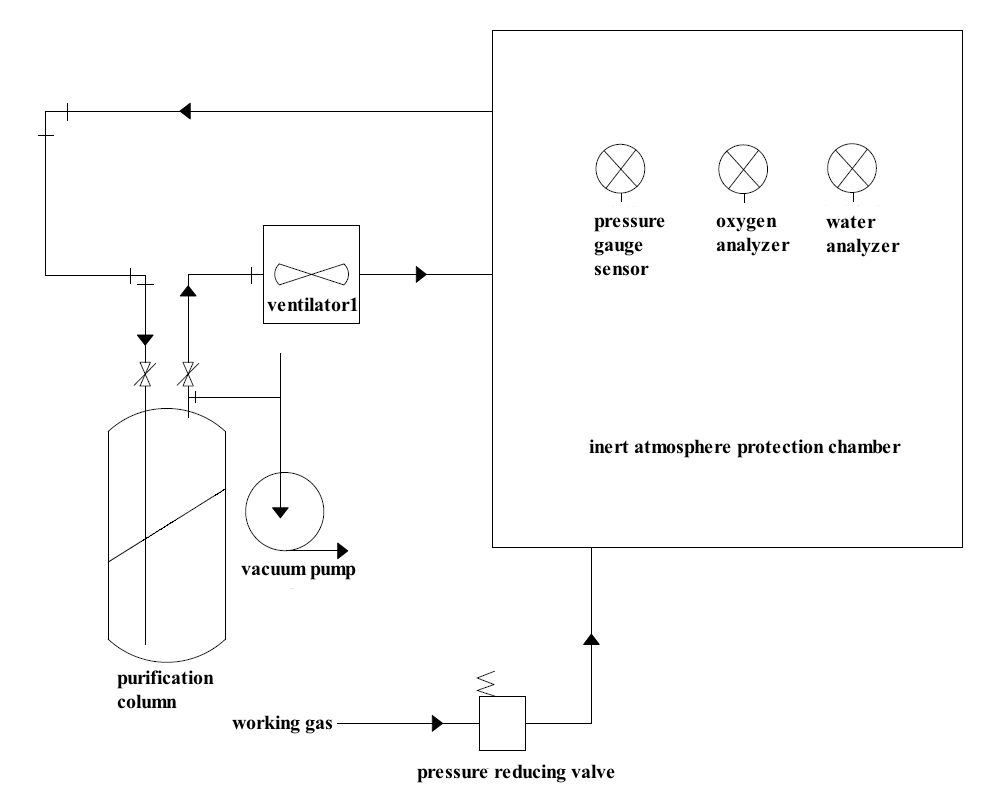

Glove box equipment schematic diagram

Product advantages and features

1. Glove box has beautiful design, compact structure and fine workmanship;

2. Glove box purification system, so that water, oxygen <1ppm

3. The equipment runs stably and can be operated continuously for a long time;

4. Simple operation; low operation and maintenance costs;

5. Glove box each part of specialization, standardization, scale production;

6. Products for a variety of special requirements of customers;

7. All parts are strictly audited and controlled;

8. Rich design and manufacturing experience;

Technical program for Lab2000

I. Acceptance criteria:

In the standard condition, i.e., 20-25℃ constant temperature, 65% relative humidity, 99.999% inert gas source, the empty box body circulating water oxygen indicators are reached less than 1ppm.

II. Main technical indicators and configuration

1. Box

1.1 Size: 800mm (L) × 720mm (H) × 650mm (W).

1.2 Material: stainless steel structure (Type 304), thickness 3mm.

1.3 Filter: pore size 0.3 micron.

1.4 Butyl rubber glove: imported from the U.S. thickness of 0.4mm, glove mouth 8 inches, hard aluminum alloy glove mouth (anti-corrosion treatment, anodized aluminum), caliber 220mm.

1.5 Window: tilted design of the operating surface, removable 8mm safety tempered glass front window, wear-resistant, corrosion-resistant, good light transmission, sealing ring using 3/8 inch thick OMEGA sealing ring

1.6. Can maintain a certain positive and negative pressure (-10mbar-10mbar) when in use.

1.7. The box is equipped with anti-reflective lighting energy-saving lamps, soft light.

1.8. The box is equipped with a multi-hole power terminal board (power supply: 220V ± 10% 50Hz ± 10%)

1.9. The box can be equipped with 3 standard KF-40 ports.

1.10. Leakage rate: ≤ 0.001 vol%/h.

1.11. No stand, can be operated on the table.

2. Transition cabinet

2.1. Shape: square (304 stainless steel), connected with the glove box, the inner door adopts sliding door, the outer door adopts flush type, easy to operate.

2.2 Dimensions: width * height * length = 250 * 250 * 400mm, the transition chamber has a sliding tray, polished, automatic control of pumping and filling.

2.3. Tray: stainless steel 190mm × 450mm, free to move the extension (used for large transition cabinet)

2.4 Vacuum degree ≤ 1bar (the large and small transition cabinets on the right are required to be vacuumed and displayed with a vacuum gauge)

3. Control system

3.1. Mode: including self-diagnosis, power failure self-starting characteristics, with pressure control and self-adaptive function. Automatic control, cycle control, password protection, vacuum chamber control adopts LCD display. Unit control adopts Siemens PLC touch screen.

3.2. Pressure control: control the pressure of the box and transition chamber at a certain set value.

a) Users can set the working pressure interval arbitrarily between +12 and -12 millibars, PLC will automatically regulate the box pressure in the set range. The default value of the working pressure interval is -1 to +3 mbar.

b) When the box pressure is greater than 12 mbar, the PLC automatically opens the safety valve to relieve pressure and protect gloves, equipment and materials inside the box.

c) Use the foot switch to fine tune the box pressure.

3.3. Foot pedal: can control the pressure of the glove box, easy to operate.

4. Circulation system (including purification and regeneration system)

4.1. Germany BASF, the United States UOP purification materials, Germany Baode valve. Host system integrated modular design, fully automatic electronically controlled gas solenoid valve group, PLC control, circuit, circulating pumps, purification of the residence, the display is integrated into an independent purifier, constituting a compact, simple system .

4.2. Control: water, oxygen control in less than 1PPm

4.3. Adjustment device: through the PLC touch regulation (heating, evacuation, purification, regeneration) in addition to the whole process of 2.5 hours of ventilation without human monitoring.

4.4. Working gas: He.N2/ or Ar gas (gas cycle)

4.5. Circulation fan: 0-30m³ high-speed frequency conversion fan, microprocessor control, after the pressure test stainless steel device.

4.6 Purification column: single purification column, imported purification material Germany BASF deoxidizing material 5kg, American UOP high efficient water absorbing material 5kg, very high life span degree, ensure the user in the use of the product in the process of the purification ability of the long lasting. In addition to the water capacity of 2.2㎏ oxygen absorption capacity of 63L.

4.7 Purification valve: full-automatic electropneumatic valve.

4.8 Filter: It adopts the high efficiency filter with 0.3 micron aperture in accordance with HEPA standard.

4.9 Regeneration: used to purify the system for reuse and activation; regeneration requires helium/H2, nitrogen/H2 or argon/H2 gas mixture, of which H2 accounts for 10%.

5. Display system

Germany SIEMENS, unit control adopts Siemens PLC touch screen. English and Chinese bilingual can be switched.

6. Water analyzer, (imported from abroad) brand material: Britain MICHELL / (in accordance with the customer's use of environmental decisions)

Non-domestic or domestic assembly, third-party data to ensure credibility.

1) Measuring range: 0-1000ppm

2) Accuracy: ±1% FS

3) Display: The output of the analyzer is connected to PLC, the detection value is displayed on the touch screen, and the alarm value can be set.

4) Control: The gas circulation system can be controlled according to the user's setting to realize the circulation drop.

5) Environment: -10 ℃ -50 ℃

7. Oxygen analyzer, PLC oxygen analyzer (U.S. AVDRAY electrochemical analyzer)

Error: ± 1% FS non-domestic or domestic assembly, third-party data to ensure credibility.

1)Measurement range can be set: 0-1000, ppm

2)Environment: -10℃ -50℃

3)Accuracy: ±1% ppm

8. Box automatic cleaning

Automatic gas control plating plate; box gas automatic cleaning function users set the cleaning time, and then touch the start button on the touch screen, the system will begin to clean the box, to the set time is automatically stopped. Increase the vacuum pump start and stop time control.

Automatic box cleaning function. Different nature of the gas environment replacement and misoperation into the water, oxygen, fast box body automatic cleaning. The box automatic clear valve to the box piping integration to KF25 steel wire with steel tubes firmly connected to the external KF25 Pagoda connector.

9. Vacuum system

Vacuum pump selection Feiyue VRD-16, pumping speed of 16m³/h, can be on the cabinet vacuum.

Working conditions of the equipment: (provided by the user)

1. Power supply: two-phase three-wire AC220V, power ≥ 1.8Kw;

2. Laboratory to have an independent ground: <3Ω, from the equipment to the ground connection is recommended to use ≥ 10mm2 flat copper wire;

3. Water supply: no;

4. Relative humidity: <75%;

5. Indoor no large amounts of dust, no corrosive, flammable and explosive gases;

6. Inert gas: working gas requirements to provide 0.4-0.6mpa, mixed gas working pressure 0.01-0.05mpa;

7. During the installation and commissioning of the gas demand side to provide, the purity of 99.999% working gas 2 bottles (40L / bottle); regeneration gas (hydrogen content of 5% -10% and the working gas mixture) 1 bottle, 40L / bottle;

8. Equipment footprint: length × width: 1200mm × 1000mm

9. Load-bearing requirements: ≤300kg/m³

Main configurations and scope of supply

No. |

Main configuration and scope of supply configuration |

Units |

Amount |

Manufacturer/Brand |

Remarks |

1 |

Enclosure |

Piece |

1 |

TMAXCN |

316 Stainless Steel Thickness 3mm |

2 |

Excess chamber |

Set |

1 |

TMAXCN |

304 stainless steel |

3 |

Control system |

Set |

1 |

Germany SIEMENS Omron electronics, etc. |

Imported assembly |

4 |

Circulation system (including purification and regeneration system) |

Set |

1 |

Germany BASF, the United States UOP purification materials, Germany Bauder valve |

Import assembly |

5 |

Display system |

Set |

1 |

Germany SIEMENS |

Imported |

6 |

Gloves |

Pair |

1 |

USA |

Imported |

7 |

Pressure gauges |

Set |

1 |

Wika, Germany |

Imported |

8 |

PLC water analyzer |

Piece |

1 |

Michell, UK |

With factory inspection report |

9 |

PLC Oxygen Analyzer |

Piece |

1 |

Avcray, USA |

Imported |

10 |

Vacuum Pumps |

Piece |

1 |

Flyover |

Domestic |

11 |

Oil Mist Filter |

Piece |

1 |

TMAXCN |

Domestic |

12 |

Pressure Gauges |

Set |

1 |

Wika, Germany |

Imported |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588