Furnace Structure

|

- Double layer steel structure with dual air cooling fans

- One pair of sliding rails is installed on bottom of furnace, which

allows furnace to be manually moved from side to side

- Vacuum flanges and a vacuum gauge are installed for

immediate use.

|

Power

|

1.5 KW

|

Voltage

|

Furnace: AC

208V~240V Single Phase, 50/60 Hz

Sliding Mechanism: AC 208V~240V Single Phase, 50/60 Hz

|

Max. Temperature

|

1200°C (<1

hour) with flowing gas

|

Continuous

Temperature

|

1100°C

|

Heating&

Cooling Rates

|

Heating

Rate:

15°C/sec (RT -

150°C);

10°C/sec (150°C -

250°C);

7°C/sec (250°C -

350°C);

4°C/sec (350°C -

500°C);

3°C/sec (500°C -

550°C);

2°C/sec

(550°C - 650°C);

1°C/sec (650°C - 800°C);

0.5°C/sec (800°C - 1000°C);

|

Cooling Rate:

15°C/sec (1000 - 950°C);

10°C/sec (950°C - 900°C);

7°C/sec (900°C - 850°C);

4°C/sec (850°C - 750°C);

2°C/sec (750°C - 600°C);

1.5°C/sec (600°C - 500°C);

1°C/sec (500°C - 400°C);

0.5°C/sec (400°C - 300°C);

|

Note: The max

heating and cooling rate is achieved by pre-heat one side of processing tube

to the target temperature and then slide the furnace to the other side. You

may choose to place the sample in the pre-heat area or not.

|

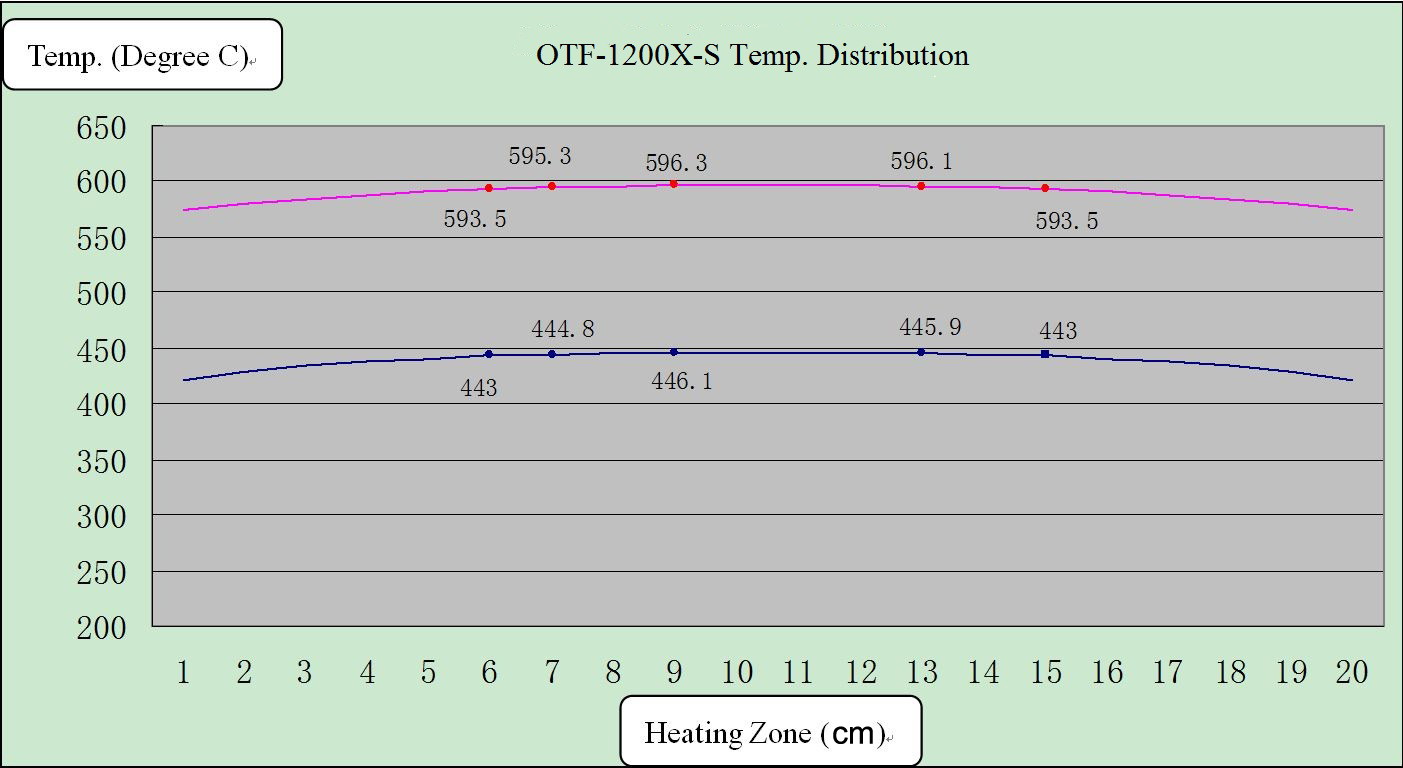

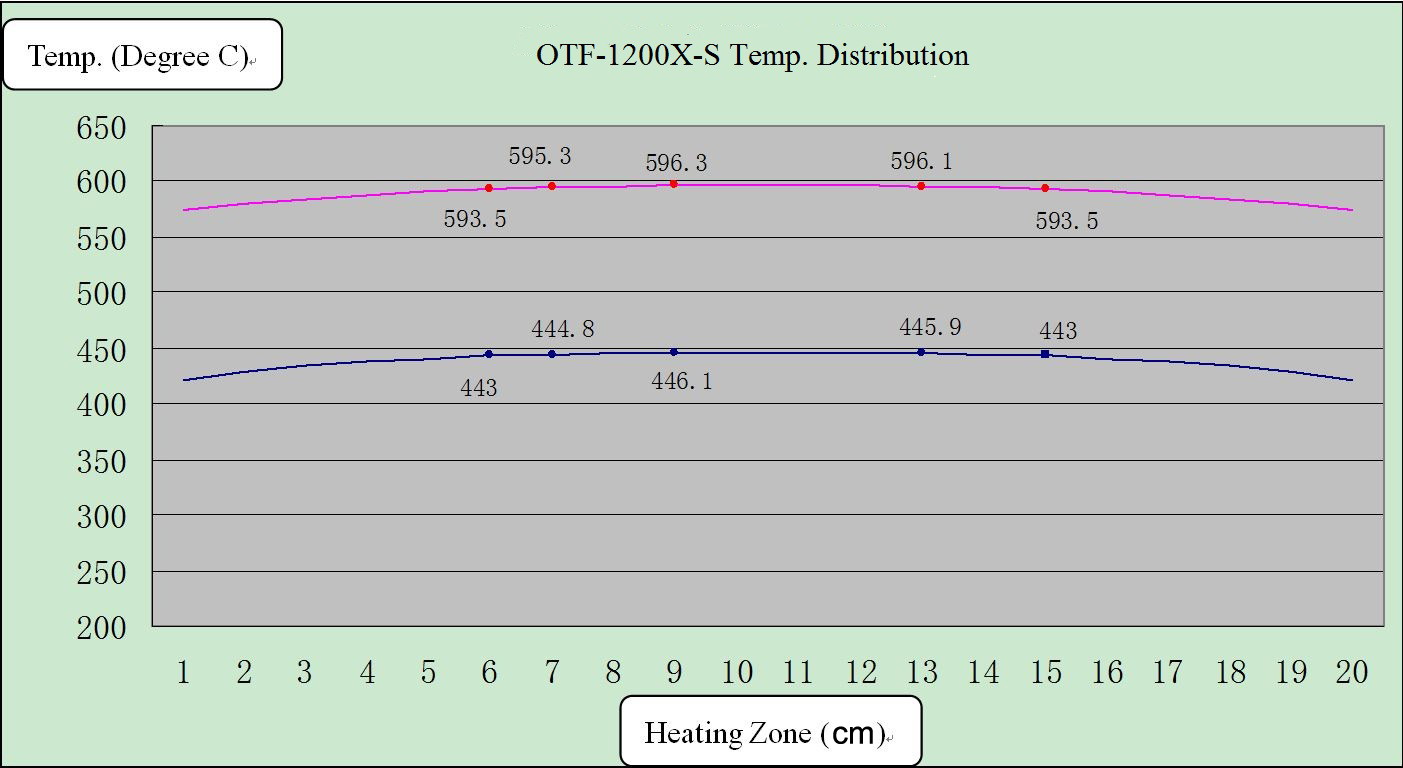

Heating Zone

Length

|

8" (200mm), single zone. The following

picture shows the temp. distribution across the heating zone, please click to

enlarge.

|

Constant

Temperature Zone

|

2.3" (60mm) (+/-1°C) @

1000 °C

|

Heating Elements

|

Fe-Cr-Al Alloy

doped by Mo

|

Processing Tube

|

- High purity fused quartz tube

- Size: OD: 2" x

ID: 1.8." x Length: 39" (inch) (50 mm OD x 46mm

ID x 1000 mm L)

- Two foam ceramic blocks are included which must be placed

inside tube to avoid heat radiation damaging the O-rings

|

Temperature

Controller

& Sliding Control

|

- 30 programmable segments for precise control of heating rate,

cooling rate and dwell time.

- Built-in over temperature alarm and protection allows for operation

without an attendant.

- K-type thermal couple is built in furnace to control furnace

temperature

- Optional:

- The furnace may be operated by PC by installing a control module.

Please order an MTS-02 control module and computer together

with the furnace at extra cost. We recommend you to order a

computer (laptop) from us to avoid software installation problems.

|

Temperature

Accuracy

|

+/ - 1°C

|

Vacuum Flanges

|

- Vacuum sealed flange with SS needle valves and vacuum gauge

is included for immediate use

- Option: Vacuum Sealing Assembly for 50 mm Dia Tube Furnace with

KF-25 Vacuum Port & 1/4 Feedthrough with Digital Gauge are

available with extra cost

|

Vacuum Level

|

- Limited by pump ( pump is not included, click on pictures to order

)

- 10E-5 torr can be

reached by molecular pump

- 10E-2 torr by a

mechanical pump.

|

Sliding

Rails / Table

|

- Double sliding rail made by Cr-plated steel

- Sliding length: 1200 mm

|

Dimensions

|

- 1200L x 400 W x 500 H, mm

|

Net Weight

|

90 kg

|

Shipping Package

Size

|

51" x

40"x 36"

|

Shipping Weight

|

230 lbs

|

Warranty

|

Two years limited

manufacturer's warranty (Consumable parts such as processing tubes,

O-rings and heating elements are not covered by the

warranty, please order replacements at related products below).

|

Laptop, software

& WiFi Control(Optional)

|

- Brand new laptop with Microsoft Window 10 and Microsoft Office 2013

(30 days free trial) for immediate use.

- Labview Based Temperature Control System enables user to edit

temperature profile, manage heat-treatment recipe, record and plot data

for MTI furnaces.

- A wireless remote control provides up to 300 meters operating

range.

- Above features are available upon request at an extra cost (up to

$1,000). Please contact us for more information.

- Note: The software is only compatible with MTI’s

Yudian Temperature Controller

|

Compliance

|

- CE Certified

- All electric components ( >24V) are UL / MET /

CSA certified

- The furnace is ready to pass TUV(UL61010) or

CSA certification at extra cost.

|

Application

Notes

|

- Tube furnaces with quartz tubes are designed for using under vacuum

and low pressure < 0.2 bars / 3 psi / 0.02 MPa

- Attention: A two-stage pressure regulator must be

installed on the gas cylinder to limit the pressure to below 3 PSI for

safe operation.

- The flow rate for gasses should be limited to <

200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube

- Vacuum limit definition for all quartz tube

furnaces: * Vacuum pressures may only be safely used up to 1000°C

- Click here to learn How to set up quartz/ ceramic

tube and vacuum flange for MTI Tube furnace.

- If you need faster cooling please click the picture below to order

a Portable Spot Air Cooling

Conditioner .

- After CVD, the graphene must be transferred from the metal catalyst

to another substrate for most applications. By using the graphene transfer tape,

the residue can be low.

- For Horizontal directional crystalization (HDC),

you may use a gas feedtrough as pic below right.

|

Warning

|

- Fast sample cooling can be achieved by sliding the heating chamber

away. Please wear protective gears such as heat resistant suit &

gloves if you intend to do so.

- DO NOT TOUCH THE TUBE SURFACE WHEN IT IS HOT!

|

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588