Site Blog

Recent Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Metal Foam

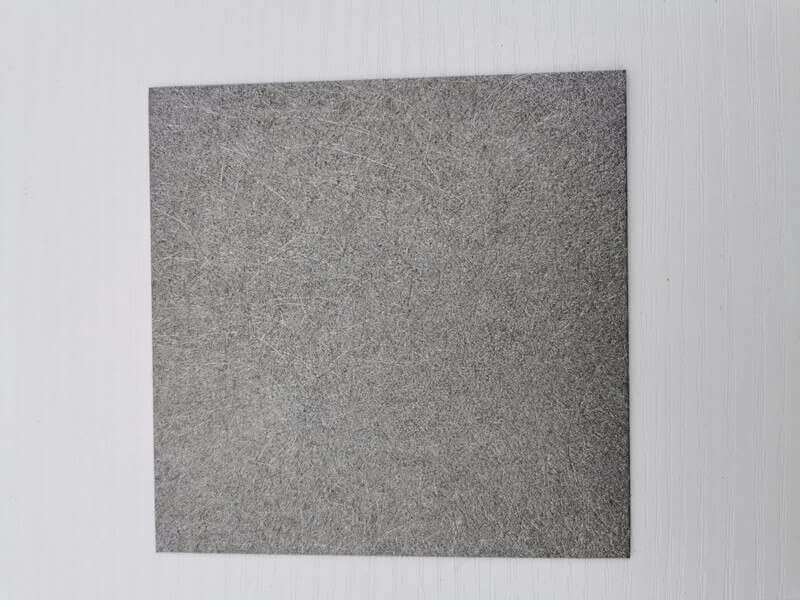

Titanium Felt

August 27,2024.

Titanium Felt: The Future of Advanced Material Solutions

In the ever-evolving landscape of material science, titanium felt is emerging as a breakthrough material with wide-ranging applications across multiple industries. Known for its exceptional properties, titanium felt offers a unique combination of strength, flexibility, and corrosion resistance that makes it a game-changer in fields like aerospace, medical devices, and energy solutions. This blog explores what titanium felt is, its key characteristics, and its potential applications.

● What is Titanium Felt?

Titanium felt is a porous, fibrous material made from titanium fibers. These fibers are interwoven and bonded together to form a mesh-like structure that retains the inherent properties of titanium while offering the benefits of a flexible, felt-like material. The manufacturing process typically involves sintering titanium fibers at high temperatures, which results in a highly durable and lightweight material.

● Key Properties of Titanium Felt

1.High Strength-to-Weight Ratio: Titanium is well-known for its exceptional strength relative to its weight. Titanium fiber felt retains this characteristic, making it ideal for applications where strength and lightweight materials are crucial.

2.Corrosion Resistance: One of the most significant advantages of titanium is its resistance to corrosion, particularly in harsh environments. Titanium felt can withstand exposure to chemicals, seawater, and extreme temperatures without degrading, which is crucial for many industrial applications.

3.Flexibility and Porosity: Unlike solid titanium, titanium felt offers a degree of flexibility due to its fibrous structure. This flexibility, combined with its porous nature, allows for applications in filtration, where the material can trap particles while still permitting fluid flow.

4.Biocompatibility: Titanium is biocompatible, meaning it does not react adversely with biological tissues. This property makes titanium felt particularly valuable in medical applications, such as implants and prosthetics.

5.Thermal and Electrical Conductivity: Titanium felt maintains good thermal and electrical conductivity, which can be leveraged in various electronic and thermal management applications.

● Applications of Titanium Felt

1.Aerospace and Defense

In the aerospace industry, titanium felt is used in lightweight structural components that require high strength and resistance to extreme environmental conditions. Its ability to withstand high temperatures and resist corrosion makes it ideal for use in jet engines, exhaust systems, and other critical components. Additionally, its porous structure allows for potential use in noise reduction systems by absorbing sound waves.

2.Medical Devices

Titanium felt's biocompatibility opens the door to a range of medical applications. It can be used in the creation of implants, where its flexibility and strength are beneficial. For instance, titanium felt can serve as a scaffold for bone growth in orthopedic implants, promoting better integration with the body’s natural tissues.

3.Energy Sector

In the energy sector, titanium felt is finding use in advanced battery and fuel cell technologies. Its porosity and conductive properties make it an excellent material for electrodes in batteries, allowing for efficient energy transfer and storage. Moreover, in fuel cells, titanium felt can act as a gas diffusion layer, enhancing the overall efficiency of the system.

4.Filtration Systems

Thanks to its porous structure, titanium felt is used in high-performance filtration systems, particularly in environments where chemical resistance is crucial. It can filter out impurities in aggressive chemical processes, making it invaluable in industries such as chemical manufacturing, oil and gas, and water treatment.

5.Automotive Industry

In the automotive sector, titanium felt is being explored for use in exhaust systems, particularly in high-performance vehicles where reducing weight without compromising strength is essential. Its ability to withstand high temperatures also makes it suitable for use in heat shields and other components exposed to extreme conditions.

● The Future of Titanium Felt

As material science advances, the potential applications of titanium felt are likely to expand even further. Ongoing research is focused on enhancing the properties of titanium felt, such as increasing its durability and conductivity. The development of new manufacturing techniques could also reduce costs, making titanium felt more accessible for a broader range of industries.

In the ever-evolving landscape of material science, titanium felt is emerging as a breakthrough material with wide-ranging applications across multiple industries. Known for its exceptional properties, titanium felt offers a unique combination of strength, flexibility, and corrosion resistance that makes it a game-changer in fields like aerospace, medical devices, and energy solutions. This blog explores what titanium felt is, its key characteristics, and its potential applications.

● What is Titanium Felt?

Titanium felt is a porous, fibrous material made from titanium fibers. These fibers are interwoven and bonded together to form a mesh-like structure that retains the inherent properties of titanium while offering the benefits of a flexible, felt-like material. The manufacturing process typically involves sintering titanium fibers at high temperatures, which results in a highly durable and lightweight material.

● Key Properties of Titanium Felt

1.High Strength-to-Weight Ratio: Titanium is well-known for its exceptional strength relative to its weight. Titanium fiber felt retains this characteristic, making it ideal for applications where strength and lightweight materials are crucial.

2.Corrosion Resistance: One of the most significant advantages of titanium is its resistance to corrosion, particularly in harsh environments. Titanium felt can withstand exposure to chemicals, seawater, and extreme temperatures without degrading, which is crucial for many industrial applications.

3.Flexibility and Porosity: Unlike solid titanium, titanium felt offers a degree of flexibility due to its fibrous structure. This flexibility, combined with its porous nature, allows for applications in filtration, where the material can trap particles while still permitting fluid flow.

4.Biocompatibility: Titanium is biocompatible, meaning it does not react adversely with biological tissues. This property makes titanium felt particularly valuable in medical applications, such as implants and prosthetics.

5.Thermal and Electrical Conductivity: Titanium felt maintains good thermal and electrical conductivity, which can be leveraged in various electronic and thermal management applications.

● Applications of Titanium Felt

1.Aerospace and Defense

In the aerospace industry, titanium felt is used in lightweight structural components that require high strength and resistance to extreme environmental conditions. Its ability to withstand high temperatures and resist corrosion makes it ideal for use in jet engines, exhaust systems, and other critical components. Additionally, its porous structure allows for potential use in noise reduction systems by absorbing sound waves.

2.Medical Devices

Titanium felt's biocompatibility opens the door to a range of medical applications. It can be used in the creation of implants, where its flexibility and strength are beneficial. For instance, titanium felt can serve as a scaffold for bone growth in orthopedic implants, promoting better integration with the body’s natural tissues.

3.Energy Sector

In the energy sector, titanium felt is finding use in advanced battery and fuel cell technologies. Its porosity and conductive properties make it an excellent material for electrodes in batteries, allowing for efficient energy transfer and storage. Moreover, in fuel cells, titanium felt can act as a gas diffusion layer, enhancing the overall efficiency of the system.

4.Filtration Systems

Thanks to its porous structure, titanium felt is used in high-performance filtration systems, particularly in environments where chemical resistance is crucial. It can filter out impurities in aggressive chemical processes, making it invaluable in industries such as chemical manufacturing, oil and gas, and water treatment.

5.Automotive Industry

In the automotive sector, titanium felt is being explored for use in exhaust systems, particularly in high-performance vehicles where reducing weight without compromising strength is essential. Its ability to withstand high temperatures also makes it suitable for use in heat shields and other components exposed to extreme conditions.

● The Future of Titanium Felt

As material science advances, the potential applications of titanium felt are likely to expand even further. Ongoing research is focused on enhancing the properties of titanium felt, such as increasing its durability and conductivity. The development of new manufacturing techniques could also reduce costs, making titanium felt more accessible for a broader range of industries.

In conclusion, titanium felt represents a significant advancement in material technology, offering a unique blend of properties that make it suitable for a variety of cutting-edge applications. Whether in aerospace, medical devices, energy, or beyond, titanium felt is poised to play a critical role in the future of advanced material solutions.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588