Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

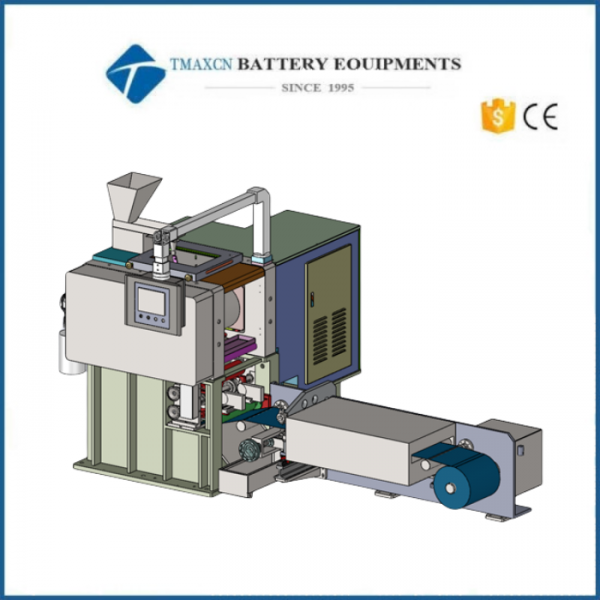

A dry electrode powder machine is an advanced piece of equipment used in the production of dry electrodes for lithium-ion batteries and other energy storage devices. Unlike traditional methods that rely on liquid slurries, dry electrode technology offers several advantages in terms of energy efficiency, environmental impact, and manufacturing costs. The dry electrode powder machine plays a key role in processing the materials that form the electrodes in energy storage devices, particularly for next-generation batteries.

● Key Features of a Dry Electrode Powder Machine

1. Powder Mixing and Processing: The machine is designed to mix and process powdered materials (such as active materials, conductive additives, and binders) without the need for solvents or liquid components. This eliminates the need for a liquid slurry process, making it more environmentally friendly and reducing energy consumption.

2. Precise Material Distribution: The machine ensures that powder materials are uniformly mixed and distributed, enabling consistent electrode performance. It typically includes systems for fine-tuning the powder size and distribution, which is critical for achieving optimal electrode performance.

3. Electrode Formation: Dry electrode powder machines often have integrated systems for shaping or forming the mixed powders into electrodes. This can involve compressing the powders into sheets, which are then used as anode or cathode electrodes for batteries.

4. Energy Efficiency: Since the machine does not require liquid-based processes or high-temperature drying, it consumes less energy and reduces waste. This makes dry electrode technology a more sustainable option for large-scale battery production.

5. Automated Control: Many modern machines feature automated control systems that monitor and adjust key parameters like pressure, temperature, and mixing speed to ensure optimal electrode quality.

● Applications of Dry Electrode Powder Machines

1. Battery Manufacturing: Dry electrode powder machines are primarily used in the production of lithium-ion and solid-state batteries, where high-performance electrodes are critical for energy density and long life.

2. Supercapacitors: In the production of supercapacitors, which require high surface area electrodes, dry electrode powder machines can be used to create electrodes with consistent thickness and uniformity.

3. Energy Storage Systems: These machines are also used in large-scale energy storage systems, such as grid storage solutions, where efficient manufacturing of electrodes directly influences the performance and cost-effectiveness of the batteries.

Required: Electrode slitting machine

4. Electric Vehicles (EVs): Dry electrodes are a promising technology for EV batteries, offering reduced environmental impact and cost savings in the manufacturing process.

● Advantages of Dry Electrode Powder Machines

1. Environmental Sustainability: By eliminating the need for solvent-based slurries, dry electrode manufacturing reduces the environmental impact associated with volatile organic compounds (VOCs) and waste generation.

2. Cost Reduction: The elimination of drying steps, reduced energy consumption, and avoidance of solvents result in significant cost savings for battery manufacturers.

3. High Throughput: These machines can be optimized for high-throughput production, making them ideal for scaling up the manufacturing of batteries for consumer electronics, electric vehicles, and energy storage systems.

4. Improved Safety: The absence of flammable solvents reduces the risk of fires or hazardous situations during production, contributing to a safer working environment.

5. Enhanced Performance: Dry electrode technology can lead to more stable and higher-performance electrodes by avoiding solvent-related issues, such as poor dispersion or uneven coating in traditional slurry processes.

● Considerations for Dry Electrode Powder Machines

1. Material Compatibility: Dry electrode powder machines need to be compatible with various active materials and additives used in different battery types. Manufacturers must ensure that the machine can handle these materials without compromising performance.

2. Process Optimization: Since the dry electrode process is relatively new compared to traditional slurry-based methods, continuous optimization and refinement of the process are necessary to achieve maximum efficiency and electrode quality.

3. Equipment Cost: While the dry electrode process can lead to cost savings in the long term, the initial investment in dry electrode powder machines may be higher compared to traditional equipment.

4. Research and Development: Manufacturers looking to adopt dry electrode technology should invest in R&D to understand the nuances of dry powder processing and ensure the best results in terms of electrode performance and battery life.

● Conclusion

A dry electrode powder machine is a pivotal tool in the evolving landscape of battery manufacturing, offering significant benefits in terms of energy efficiency, sustainability, and cost-effectiveness. By eliminating the use of solvents and drying steps, it streamlines the production of high-performance electrodes for batteries, supercapacitors, and energy storage systems. As the demand for cleaner and more efficient energy storage solutions increases, dry electrode technology is poised to play a critical role in advancing the next generation of battery manufacturing.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588