Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

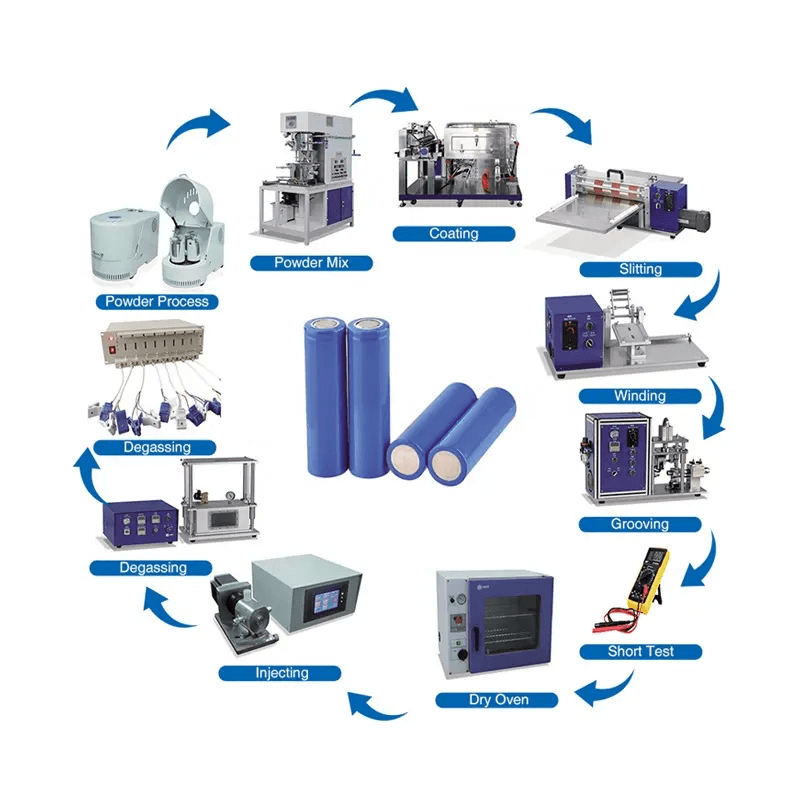

A cylindrical cell fabrication machine is a specialized piece of equipment used for the automated production of cylindrical lithium-ion battery cells. This type of machine typically consists of multiple components, including equipment for electrode manufacturing, cell assembly, and formation. The electrode manufacturing stage involves the preparation of the anode and cathode materials, which are then coated onto a substrate to form the electrodes. The cell assembly stage involves the stacking of the electrodes with a separator and assembling the components into a cylindrical cell. The formation stage involves the initial charging and discharging of the cell to activate the electrochemical reactions and optimize performance. These stages are typically carried out in a controlled environment, such as a glove box, to minimize exposure to moisture and other contaminants.

Cylindrical cell fabrication line are essential for the mass production of high-quality lithium-ion battery cells, which are used in a wide range of applications, including electric vehicles, portable electronics, and grid storage systems. These machines are designed to operate with a high level of precision and accuracy, producing cells that meet strict quality standards for energy density, cycle life, and safety. Ongoing research and development in this area are focused on improving the efficiency and scalability of the production process, as well as developing new materials and chemistries to enhance battery performance and reduce costs.

The cylindrical cell fabrication machine is designed to have several key features that are essential for the automated production of high-quality lithium-ion battery cells. Some of the main characteristics of these machines include:

High precision and accuracy: These machines are designed to operate with a high level of precision and accuracy, ensuring that each cell produced meets strict quality standards for energy density, cycle life, and safety.

Scalability: Cylindrical cell fabrication machines are designed to be highly scalable, allowing for large-scale production of battery cells that can be used in a wide range of applications, from electric vehicles to portable electronics.

Flexibility: These machines are designed to be highly flexible, accommodating a wide range of cell sizes and chemistries. This allows manufacturers to produce a diverse range of battery cells to meet the needs of different industries and applications.

Automation: Cylindrical cell fabrication machines are highly automated, with many of the production processes being carried out by robotic arms and other automated equipment. This not only reduces the need for manual labor but also improves the consistency and quality of the cells produced.

Environmental control: The production of lithium-ion battery cells requires a controlled environment to minimize exposure to moisture and other contaminants. Cylindrical cell fabrication line are typically housed in a cleanroom or glove box environment to maintain a high level of environmental control.

The cylindrical cell fabrication plant is a highly specialized piece of equipment that is essential for the mass production of high-quality lithium-ion battery cells. These machines are designed with a range of advanced features to ensure that each cell produced meets strict quality standards and can be used in a wide range of applications, from electric vehicles to portable electronics and grid storage systems. Ongoing research and development in this area is focused on improving the efficiency and scalability of the production process, as well as developing new materials and chemistries to enhance battery performance and reduce costs.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588