products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

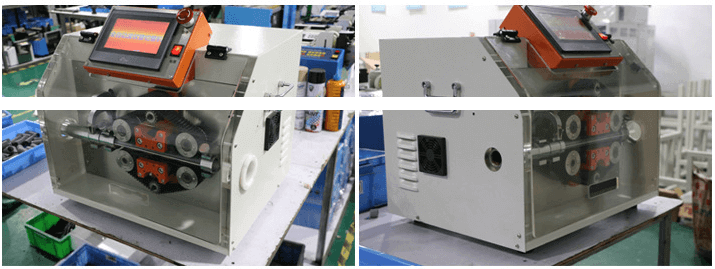

Automatic Plastic Pipe Corrugated Pipe High Voltage Cabinet Wiring Harness Aerospace Cutting Machine

Model Number:

TMAX-HZX-B110Dimension(L*W*H):

L570*W470*H510mmNet Weight:

46KGCompliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Cutting Machine for PVC Film/PE Film/Kraft Paper/Insulation Paper/Copper Foil/aluminum foil/Plastic Sheet/Non Woven FabricNext:

Automatic Label Film Reflective Film Plastic Film Protectivefilm Mobile Phone Film Plastic Film Cutting Machine

Automatic Corrugated Pipe High Voltage Cabinet Cutting Machine

Features :

1. This machine is specially designed for the corrugated pipe processing of automobile wire harness industry. High precision PLC control, easy to operate and understand.

2. The machine is used for cutting round plastic hose and ripple, with high processing efficiency, stability and reliability.

3. This machine adopts stepper motor feeding, which has the characteristics of stable feeding and accurate length.

4. This machine adopts integrated circuit, accurate and stable control, simple maintenance, full touch screen operation, and easy data.

Material :

Applicable to automotive wiring harness , new energy wiring harness , aerospace , motorvehicles , urban rail transit , high voltage cabinet , etc.

The machine is designed for long cutting and high demand bellows products with belttraction , using displacement sensors , positive res

ponse to pre-placed pipe , activetransport , to achieve high speed and accuracy , touch screen , PVC control , digitaloperation , integrated circuits , control stability , easy maintenance , improve productionefficiency every day.

Specification:

Model |

TMAX-HZX-B110 |

Power Supply |

AC220V 50/60HZ |

Power |

1.1KW |

Shape size |

570'470,510MM |

Weight |

46KG |

Cutting precision |

±0.1MM |

Shear length |

0.1-9999MM |

Trip |

30MM |

Machining diameter |

®5-®30MM ( O40MM Customizable) |

Shear velocity |

60510times/min L・100MM |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588