products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic High Performance Surface Area And Aperture Analyzer

Model Number:

TMAX-BSDCompliance:

CE CertifiedWarranty:

2 years warranty with lifetime supportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab High Performance Specific Surface Area And Micropore AnalyzerNext:

Automatic Nitrogen Adsorption BET Pore Size Analyzer Specific Surface Area Analyzer

Automatic High Performance Surface Area And

Aperture Analyzer

Product overview:

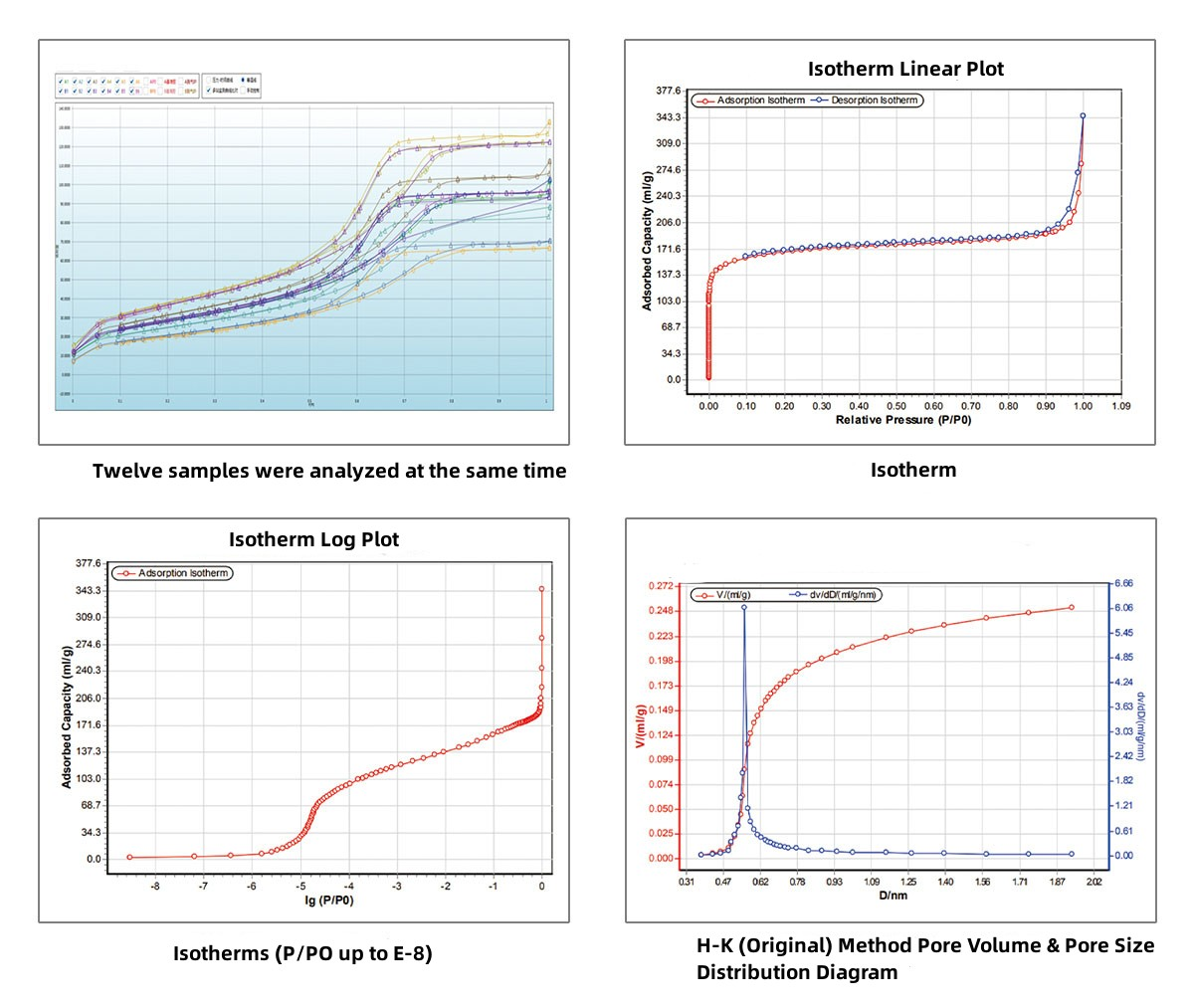

◆ Specific surface area, mesopore, micropore and ultramicropore analysis

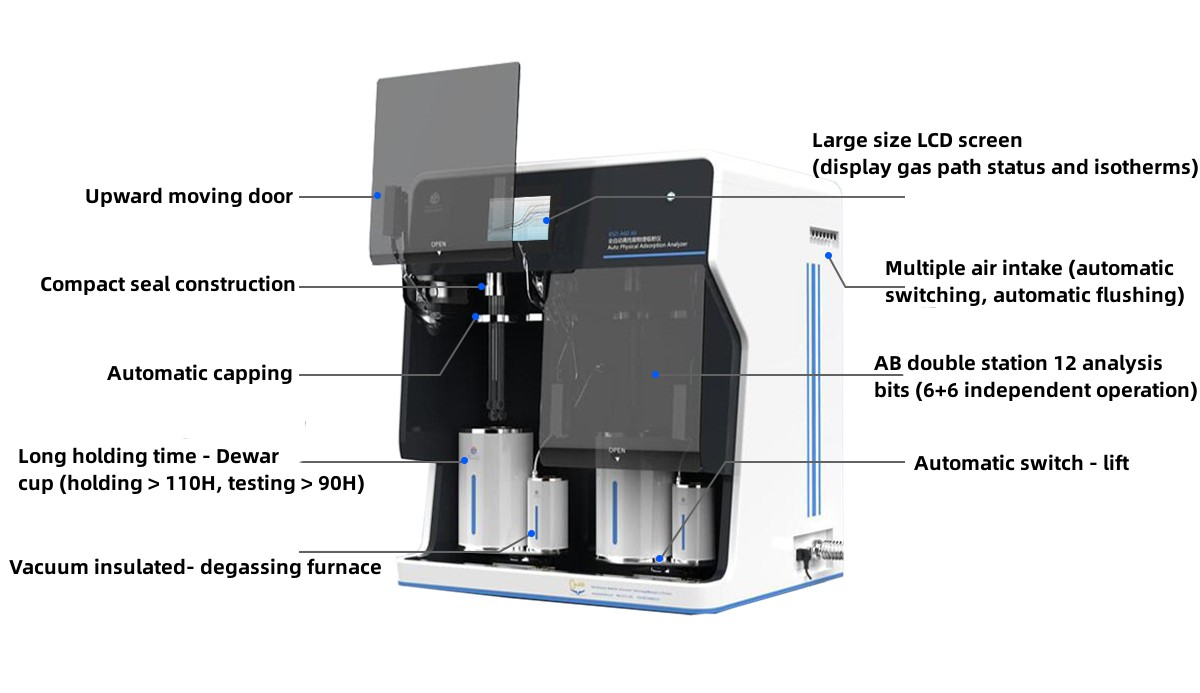

◆ High throughput analysis: up to 12 samples can be analyzed at the same time

◆ Fully automatic: degassing → testing, fully automatic switching, without human intervention

Main functions:

◆ Full function: specific surface area, mesopore, micropore and ultramicropore analysis;

◆ High throughput: 3/6/9/12 analysis digits are optional;

◆ Fully automatic: degassing → testing, fully automatic switching;

◆ High configuration: double station double molecular pump set is selected for degassing;

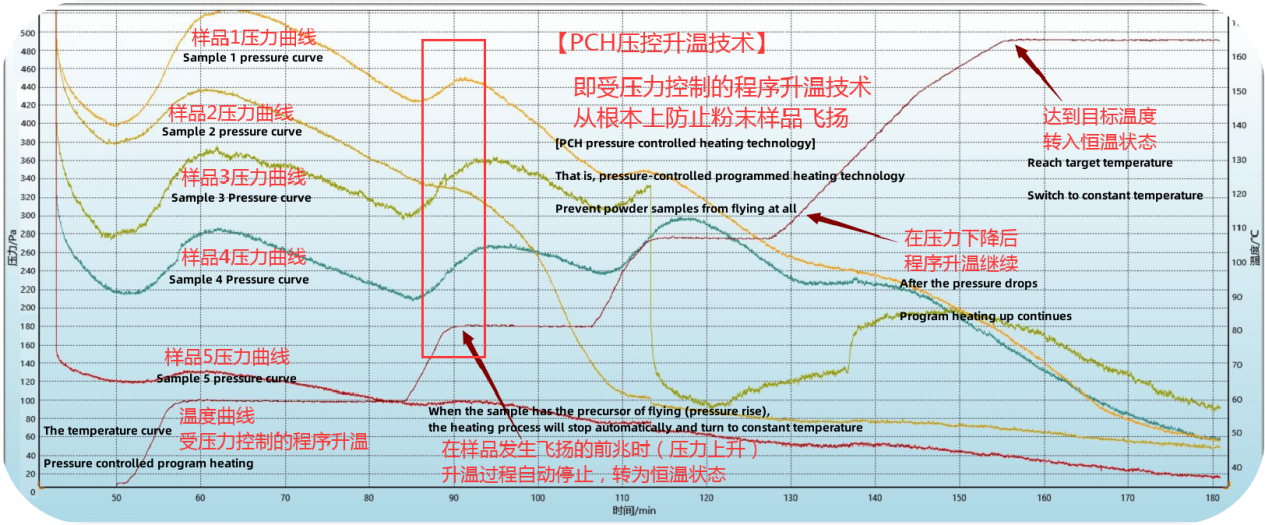

◆ Pollution prevention: microporous samples are "pressure controlled temperature rise" to prevent pollution and degassing;

◆ Zero helium pollution: first helium temperature measurement area, then automatic degassing;

◆ Automatic circulation: automatic evaluation of material circulation and adsorption performance;

Technical parameters:

◆ Wide test range: the specific surface area is above 0.0005 ㎡/g, and the aperture is 0.35-500 nm;

◆ High test accuracy: specific surface area, pore diameter, pore volume, adsorption capacity ≤ 1% RSD (standard sample);

◆ Programmed temperature rise and degassing: the software controls the programmed temperature rise, the room temperature is - 400 ℃, and the accuracy is better than 0.1 ℃;

◆ Intelligent degassing completion judgment: support software automatic judgment, and automatically judge degassing effect according to pressure change;

◆ Anti flying degassing: "programmed pressure control"+"programmed temperature control"+"degassing furnace lifting"="pressure controlled temperature rise";

◆ Vacuum degree: 10-2Pa, molecular pump is selected, and the vacuum degree can reach 10-8Pa;

Characteristic structure:

Technical advantages:

◆ High throughput and efficiency: support analysis of up to 12 samples at a time;

◆ Real full automation: the internationally initiated degassing furnace and Dewar cup can be switched automatically without manual transfer of sample tubes or degassing furnace;

Patent name: Full automatic physical adsorption instrument with automatic position switching between heating furnace and thermostatic bath cup

Patent No.: ZL20220232044.8;

◆ High time utilization rate: It solves the problem of time waste when conventional instruments can not enter the test after degassing is completed after work, making it a reality to load samples after work and look at data at work;

◆ Thoroughly eliminate "helium pollution": helium test dead volume → vacuum heating degassing → adsorption test is the first internationally to solve the helium pollution problem of micropore analysis and improve the test accuracy;

◆ Anti flying degassing: support "program pressure control"+"program temperature control" degassing, and automatically lift the degassing furnace according to the pressure change, which will prevent the sample from flying;

Patent name: Physical adsorber with programmed pressure control anti flying degassing system

Patent No.: ZL202020230457.2;

◆ Support automatic cycle test: automatic degassing+test cycle test, which is used to evaluate the stability of material adsorption performance and the life of adsorption performance;

"Pressure controlled heating" anti flying degassing technology

That is, the temperature programmed technology under the control of gas pressure automatically starts and stops the temperature programmed according to the pressure change, fundamentally preventing the sample from flying;

Patent name: Physical adsorber with programmed pressure control anti flying degassing system

Patent No.: ZL202020230457.2

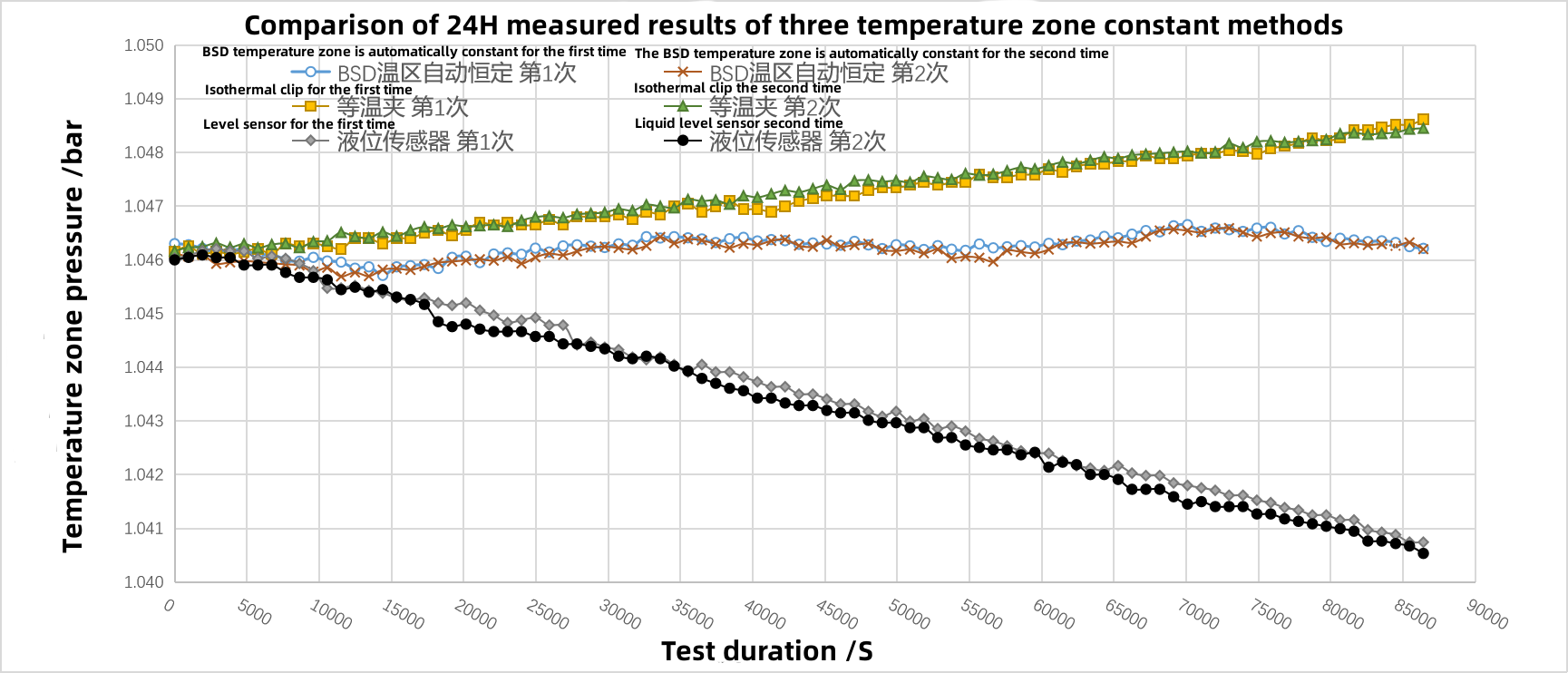

"Automatic and constant temperature zone" patented technology

The curve shows that the change rate of the "equivalent volume of the adsorption chamber" of the three ways of temperature zone constant effect in 24 hours is: BSD temperature zone servo automatic constant: 0.10%, isothermal clamp: 0.25%, liquid level sensor: 0.55%

Patent name: Physical adsorption instrument with automatic and constant temperature zone structure

Patent No.: ZL2018 2 0401132.9

◆ Convenient installation and sealing: one-time sealing technology for 6 sample tubes in a single analysis station eliminates the need to seal each tube one by one, providing an unparalleled efficiency experience;

Patent name: a kind of physical adsorber with dense multi tube co sealed tube jacket Patent No.: ZL 2019 2 1078195.6;

◆ Full constant temperature of gas circuit system: the internal gas circuit system of the instrument is fully constant temperature to 40 ℃, with accuracy better than 0.1 ℃;

◆ Up moving door: user-friendly and easy to open and close, saving laboratory space;

Patent name: Physical adsorber with upper and lower open type protective cover Patent No.: ZL202022203243.9;

◆ Electric turbine liquid nitrogen pump: humanized liquid nitrogen addition, stepless speed regulation, random movement, safe and convenient, and no pollution of liquid nitrogen;

Patent name: an electric liquid nitrogen pump with impeller structure (non pneumatic) Patent No.: ZL 2017 2 0864873.6;

◆ High reliability: international supplier system, core components are imported with original packaging;

Data report:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588