products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- BMS Testing Machine

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- Laser Welder

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Die Cutter Machine With Roll To Roll System For Lithium Battery Electrode Cutting

Model Number:

TMAX-ZDMQ-350Compliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

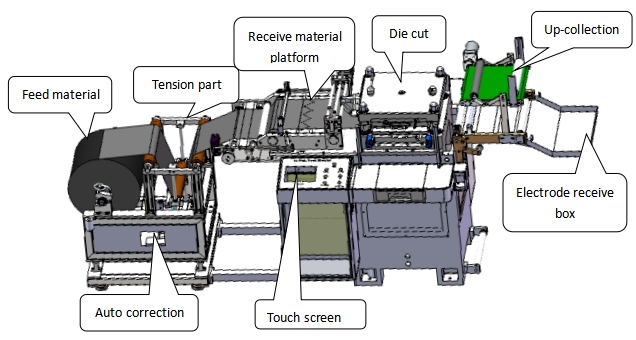

Automatic Die Cutter Machine With Roll To Roll System For Lithium Battery Electrode Cutting

Function overview

1. The device is suitable for automatic die-cutting of lithium battery electrode.

1.2 Operation process:

The coil material of the pole piece is controlled by the variable frequency motor. After the tension float roller and the precision correction mechanism, the circulating conveyor belt of the highland wheat paper driven by the servo motor is sent to the die-cutting machine. After the die-cutting, the edge material is collected by the edge material receiving mechanism, and the pole piece automatically flows into the tray.

1.3 Action process:

Auto unwinding → Unwinding correction → Tension & Material storage → Receiving platform → Die-cut part → up-collection → Automatically drop into the receiving box

Technical parameters

1. Incoming material size: ≤ width 300, diameter ≤¢400;

2. The equipment can produce the product specification range: 300X300

3. Incoming material thickness: 20-180um

4. Qualified rate of equipment products: ≥98%;

5. Equipment production speed :30-40 times/min;

6. Equipment failure rate: ≤5% (only caused by equipment failure);

7. Punching dimensional accuracy ≤0.1mm, burr ≤0.015mm

8. Equipment electrical: voltage AC220±10%, power ≤4.5KW;

9. Compressed air: ≥0.6MPa;

10. Weight: 2.0T

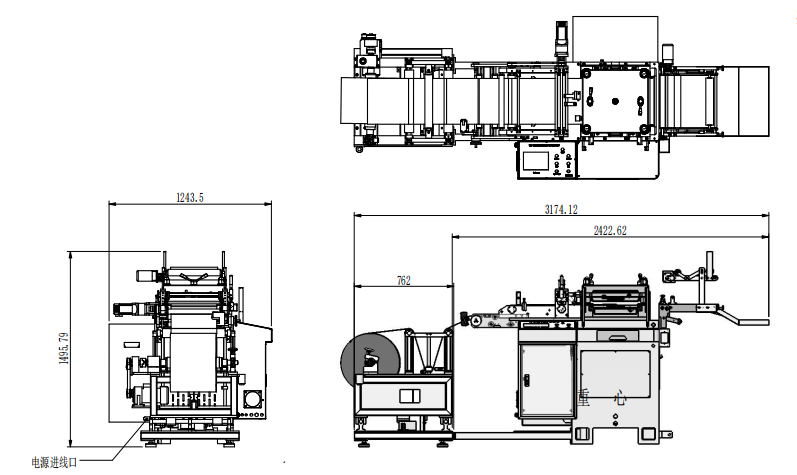

11. Dimensions: 3200*1250*1500mm (length x width x height)

Process performance

1. Variable frequency motor and position detection potentiometer intelligent variable speed unwinding;

2. Adopt floating roller mechanism to maintain appropriate tension of pole sheet;

3. Precision servo correction mechanism, with correction sensor, to achieve high-precision closed-loop control correction;

4. The feeding roller is Baodingqing rubber roller, driven by servo motor and secret reducer, accurate feeding;

5. Single-seat high-speed die-cutting machine base, improve production capacity;

6.PLC program control, touch screen can set step accuracy and die cutting parameters;

7. Unique pull-belt type edge receiving mechanism, smooth and smooth edge receiving, continuous feeding;

8. The lower level of the die cutting platform is controlled by a stepper motor, which can manually adjust the step displacement of each rise or fall on the touch screen

Main component configuration

1. Mechanical part:

l Unwinding and correcting mechanism:

Fangtong paint main frame, frequency conversion motor, servo push rod, brown surface with duralumin roller, and other chrome-plated metal parts, aluminum parts.

l Forward overroll mechanism:

Chrome-plated metal parts, chrome-plated metal rollers.

l Roller feeding mechanism:

Chromium-plated metal base, servo motor, planetary reducer, Balding rubber roller, connecting press cylinder, connecting stainless steel platform.

l Die cutting mechanism:

Casting frame, metal transmission, moving parts

l Trimming mechanism:

Speed regulating motor, chrome-plated metal roller, aluminum alloy side plate, highland barley paper conveyor belt.

List of main equipment accessories

5.1 List of main parts:

No |

Main configuration |

Brand |

Place of origin |

1 |

PLC control system |

Panasonic |

Japan |

2 |

Correct a deviation |

Li Xun |

China |

3 |

Touch screen |

Velen |

China |

4 |

servomotor |

Panasonic and domestic |

Japan |

5 |

Pneumatic element |

Airtac |

Taiwan |

6 |

Proximity switch |

Made in China |

China |

General equipment configuration and standards

1. Device appearance color: customer provided color palette.

2. Device noise ≤60 db.

3. The equipment meets the national safety standards for mechanical and electrical equipment, and there are no obvious or potential design safety hazards.

4. The operation manual and equipment maintenance manual in Chinese are included.

5. Random delivery of machine electrical control diagram, pneumatic control diagram, and purchased parts instructions and other materials.

6. Provide a list and drawings of each part for replacement.

7. Provide a list of wearing parts, including name, number of units, specifications or drawings, brand, estimated life and other information.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588