products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

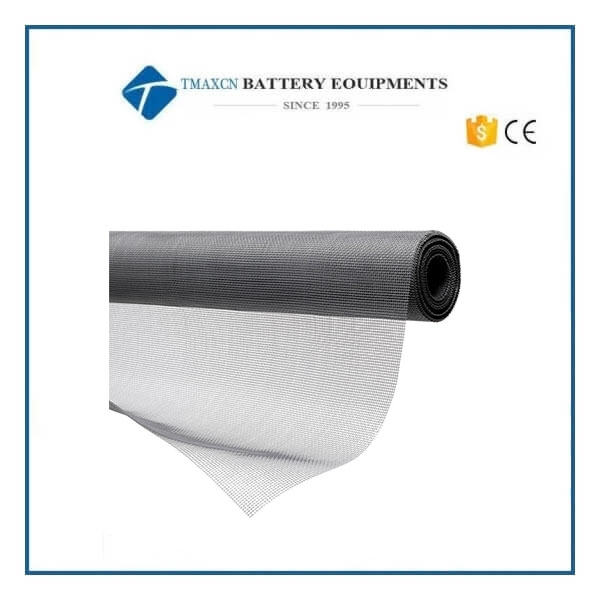

Aluminum Wire Mesh for Advanced Energy Storage Applications in the Battery Industry

Model Number:

TMAX-AlM01Compliance:

CE CertifiedDelivery Time:

2 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Aluminum Wire Mesh for Battery Electrode ApplicationsNext:

Titanium Wire Mesh for Battery Applications

Aluminum Wire Mesh for Advanced Energy Storage Applications in the Battery Industry

Introduction

Crafted from high-quality aluminum wire through plain or twill weaving techniques, our aluminum wire mesh is available in two variants: raw edge aluminum wire mesh and hemmed edge aluminum wire mesh, featuring square or rectangular mesh openings.

Features:

Exceptional Conductivity:

The aluminum mesh ensures swift and efficient electric current flow within battery electrodes, optimizing overall battery performance.

Low Resistance, High Conductivity:

With low electrical resistance, the aluminum mesh minimizes energy losses during charge and discharge cycles, enhancing battery efficiency and stability.

Increased Surface Area:

The open structure of the mesh augments the surface area of battery electrodes, promoting better contact between electrode materials and the electrolyte, resulting in improved energy storage capacity.

Lightweight and Corrosion Resistance:

Aluminum's lightweight nature contributes to reducing the overall battery weight, particularly advantageous for portable electronic devices. Additionally, its corrosion resistance extends the battery's lifespan.

Flexibility and Malleability:

The aluminum mesh exhibits excellent flexibility and malleability, accommodating diverse shapes and sizes in battery designs, providing versatility in battery applications.

Sustainability:

As a recyclable material, aluminum supports sustainability initiatives by reducing the reliance on new resources in battery production, aligning with environmental standards.

Applications:

Lithium-ion Batteries

Portable Electronic Devices

Energy Storage Systems

Electric Vehicles

Renewable Energy Storage

To customize various metal foams, please click the picture below for details:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588