products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

5V 20A 128 Channels Prismatic Battery Energy Feedback Life Cycle Tester

Model Number:

TMAX-EF128-20KInput Power:

13KWDimension(L*W*H):

L1850mm*W550mm*H1840mmCompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

ChinaMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

64 Channel 5V 60A Prismatic Battery Charge Discharge Capacity TesterNext:

5V 30A 128 Channel Prismatic Cell Tester with Energy Regenerative Function

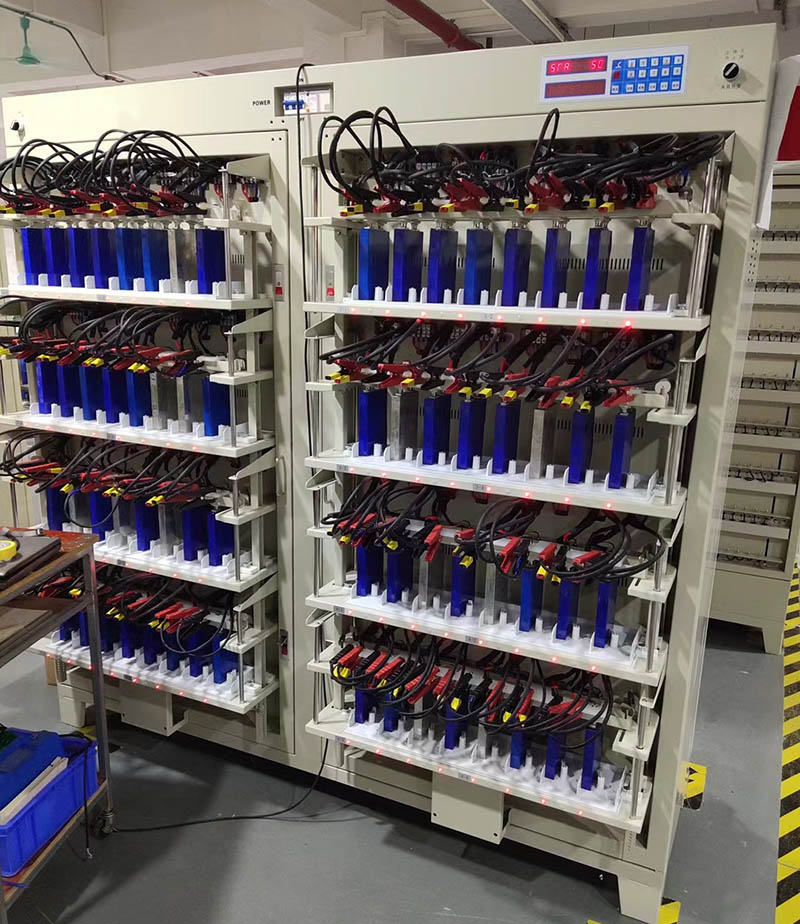

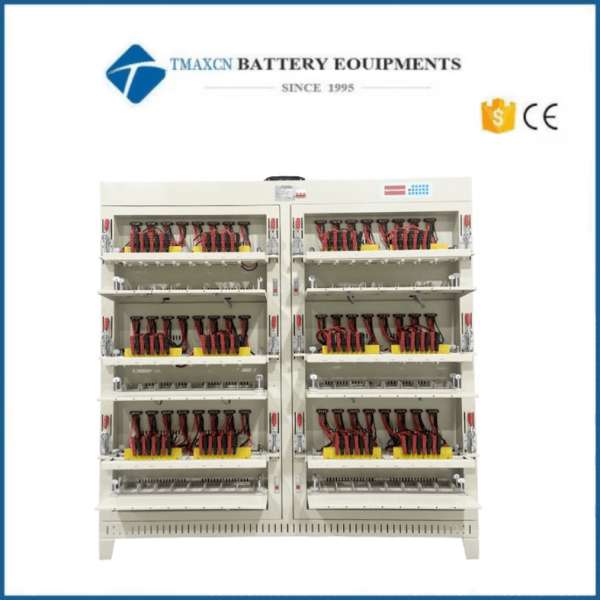

5V 20A 128 Channels Prismatic Battery Energy Feedback Life Cycle Tester

1.Overview

The energy feedback type square battery charge and discharge test machine is used to test the capacity, cycle life, internal resistance, energy density, temperature characteristics and other parameters of the battery, so as to evaluate the performance and reliability of the battery. This test cabinet adopts the energy-saving technology to feed the energy released by the battery back to the power grid, so as to realize the energy-saving, efficient and reliable test process. It is widely used in lithium-ion batteries and nickel-metal hydride batteries formation and capacity testing of nickel-cadmium batteries. The product's stability, energy saving, precision and quality have been welcomed and praised by many battery industries.

2.The Structure And Appearance Of The Equipment

The structure of this equipment is mainly composed of the following parts:

1)One CPU board, the whole cabinet sends and controls uniformly.

2)There are 32 four-channel constant current plates, arranged evenly in four doors.

3 bidirectional inverter power supplies, each for 8 constant current boards.

4)Two keyboard boards, front and rear double-sided operation.

5)A total of 16 pallets, the depth of the pallet is 22cm, the epoxy board is attached for insulation, each pallet has 8 channels, and the downward pressure clamp.

3.System Structure And Working Principle

System composition

1)Lithium battery pack equipment (1-10 units).

2)A computer with USB interface (provided by yourself).

A USB to 485 interface converter and communication line.

A set of TMAX product software.

4.Working Principle

The equipment is connected and controlled by a computer, sending instructions and collecting data, etc.; the keyboard can manually operate the equipment, displaying parameters and status; the constant current board is ordered by the CPU, and has constant current and constant voltage functions; when the battery is charged, the bidirectional power supply converts AC power to 12V Direct current, through the constant currentboard to realize the charging control and detection of the battery; when the battery is discharged, the process is opposite to charging, the battery voltage is first raised to 12V through the constant current board, and then the direct current is converted into alternating current through the bidirectional power supply. Into the AC power distribution network of the factory, thus realizing the energy feedback of the discharged electric energy of the battery.

Significant power-saving effect: According to actual measurement, the power consumption of the device during charging is reduced by more than 40% compared with that of traditional devices. The comprehensive power-saving rate is more than 60%, and the power consumption is more than 60%, which saves a lot of cost for battery manufacturers.

Structure Of Equipment |

|

Number Of Device Channels |

128 Channels |

Overall Dimension |

Width 1850mm× Depth 550mm× Height 1840mm |

Color |

Dark Grey |

Jig Form |

Push Down Four Wire Method Fixture |

Fixture Spacing |

85mm |

Battery Type |

Prismatic Cell |

Working Power Supply |

Three-Phase Five-Wire Ac380V±10%, 50Hz |

Ac Current Distortion Rate |

≤5% |

Power Consumption |

≤13Kw |

Power Factor |

≥0.99 |

Charging Efficiency Of Whole Machine |

≥75% |

Feeder Net Conversion Efficiency |

≥70% |

Equipment Failure Rate |

<1% |

Work Environment |

Temperature -10 ~ 40℃, Relative Humidity ≤80% |

Heat-Dissipating Method |

Natural Air Intake And Upward Exhaust |

Channel Parameters |

|

Voltage Testing Range |

Dc 0~5V |

Battery Voltage Range |

Charge Dc 0~4.5V;Discharge Dc 4.5~2V |

Constant Voltage Range |

Dc 1~5V |

Voltage Accuracy |

±(1‰ Reading +1‰ Full Degree), Resolution 1mv |

Voltage Stability |

≤1‰ |

Current Range |

Charging Dc 200ma ~ 20A; Discharge Dc 200ma ~ 20A |

Accuracy Of Current |

±(1‰ Reading +1‰ Full Degree), Resolution 10ma |

Current Steady Reading |

≤1‰ |

Software Function |

|

Control Mode |

Computer Control Equipment Work |

Communication Mode |

Serial Port, Baud Rate 57600 |

Workflow Setting |

Up To 32 Work Steps And 256 Cycles Can Be Set, With

The Function Of Nested Loops |

Charging Mode |

Constant Current Constant Voltage |

Charge Cutoff Condition |

Voltage, Current, Time, Capacity |

Discharge Mode |

Constant Current |

Discharge Cutoff Condition |

Voltage, Time, Capacity |

Protection Function |

Over-Voltage, Under-Voltage, Over-Current, Under-Current, Over-Capacity Protection, Outage Protection, Data Breakpoint Recovery |

Time Range |

0~ 30000 Minutes/Work Step, Time Unit Is Min |

Time Accuracy |

≤±1‰ |

Sampling Tour Period |

≤1s~60s Optional |

Battery Grading |

Sort According To (Capacity, Time, Open Circuit Voltage,Discharge Platform, Etc.) |

Data Processing |

Can Record Voltage, Current, Time, Capacity And Other Data, Automatic Calculation Of Constant Current Charging Ratio, Capacity Loss Discharge Efficiency, Average Voltage, Median Voltage And Other Data, Data Curve Diagram And Cycle Diagram; Can Output Generated Text, Excel, Word Or Mdb Database Format Files |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588