products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

30T 40T 60T Hydraulic Press Automatic Powder Tablet Press

Model Number:

TMAX-ZYP-TCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Stainless Steel Small Press Mold with 30mm Depth ChamberNext:

500C 25T Multi-segment Programmable Automatic Plate Hot Press

30T 40T 60T Hydraulic Press Automatic Powder Tablet Press

Dear Customers:

Welcome to use our ZYP-T series automatic tablet press, please read the instruction manual carefully before using and use it in strict accordance with the instruction manual operating procedures. Remember not to operate blindly to avoid personal or property damage.

![]()

WARNING!!!

Please pay attention to the pressure range of the machine and the upper limit of the pressure of the mold. Remember not to use it with overpressure to avoid danger; During the use of the machine, you need to check the machine from time to time and perform maintenance, in case of any abnormality, please contact our after-sales engineer as soon as possible.

1.Machine Introduction:

Powder press (also known as small hydraulic press) is hydraulically driven, mainly used in laboratory small-scale powder molding sample making. They need to be used in combination with molds and are widely used in X-fluorescence, calcium-iron analysis, superconductivity, building materials, ceramics, cement, and other new materials research and development fields.

This instrument is the third generation of automatic tablet press developed by our company combining the existing tablet presses on the basis of the suggestions and support from the teachers of universities. Many optimizations and improvements have been made in this upgrade to achieve precise pressure control and meet the customers' demand for multi-stage pressurization, in addition, many safety configurations have been added, which is suitable for high-end laboratory use.

2.Main Technical Parameter:

Model name |

ZYP-10T |

ZYP-20T |

ZYP-30T |

ZYP-40T |

ZYP-60T |

Pressure range |

0.2-10.0T |

0.2-20.0T |

0.2-30.0T |

1.0-40.0T |

1.0-60.0T |

Cylinder diameter |

Ф65mm |

Ф95mm |

Ф110mm |

Ф130mm |

Ф150mm |

Cylinder stroke |

30mm |

50mm |

|||

Pressurization method |

Electric pressurization |

||||

Pressurization process |

5 Stages pressurization - 5 Stages pressure retention - Automatic pressure replenishment - Timed pressure release |

||||

Number of pressurized sections |

5 stages pressurization can be set arbitrarily |

||||

Release pressure |

Can be set by yourself |

||||

Pressure holding time |

Unlimited time (N seconds) |

||||

Display |

7 inch touch LCD screen |

||||

Mold pressure conversion |

The program automatically converts/directly displays the pressure (Mpa) of the sample |

||||

Cylinder limit protection |

The cylinder automatically relieves pressure when it exceeds the limit height |

||||

Active security configuration |

When it detects that the system pressure reaches the safe pressure of the machine, it will automatically release the pressure. |

||||

Passive safety configuration |

Emergency stop switch +steel plate protection +plexiglass protective cover |

||||

Data management |

Can be managed, stored, checked, and exported via USB |

||||

Power supply |

220V(50Hz/60Hz) |

||||

Work space |

Width:140×160mm |

Width:175×180mm |

Width:185×220mm |

||

Measurement |

230×390×420mm |

280×460×550mm |

300×520×580mm |

||

Weight |

Appr. 95kg |

Appr. 150kg |

Appr.180kg |

||

Remark: Above are our standard tablet press, it can be customized or improved according to customer needs.

3.Operation Guide:

1)Setting Procedure:

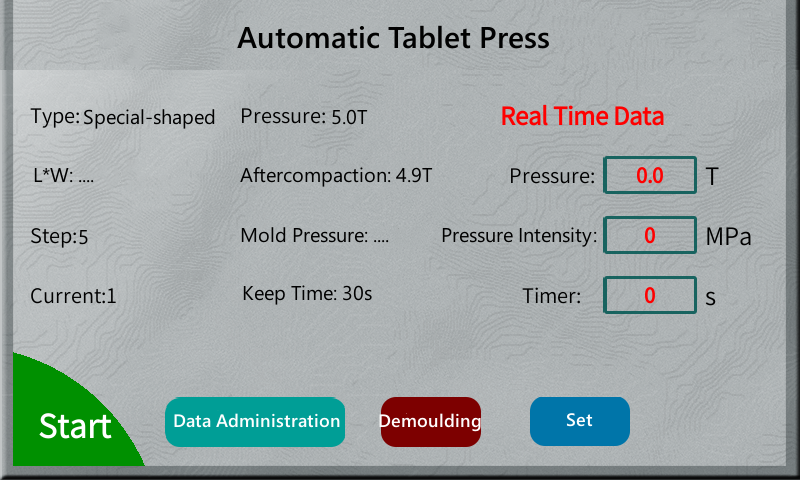

Plug in the power, start the switch, the device enters the power-on stage, the screen automatically lights up, enter the main interface, press the [Settings] button on the screen, and enter the pressure setting page:

As shown above picture 1(Main interface)

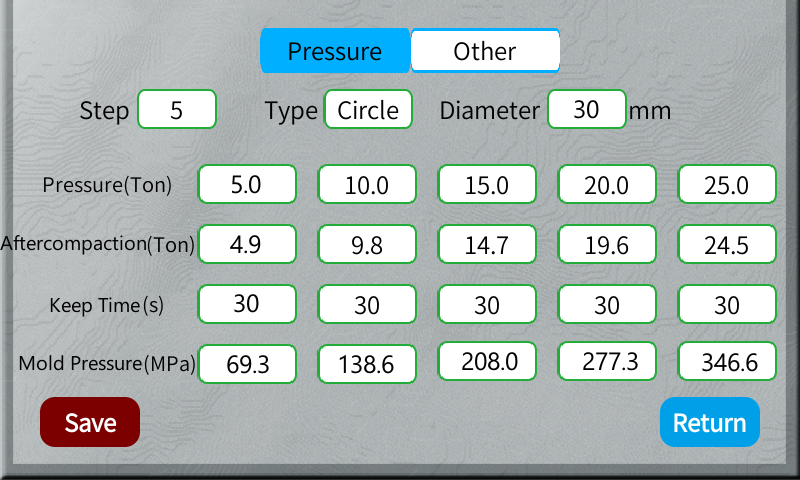

Pressure setting and other settings:

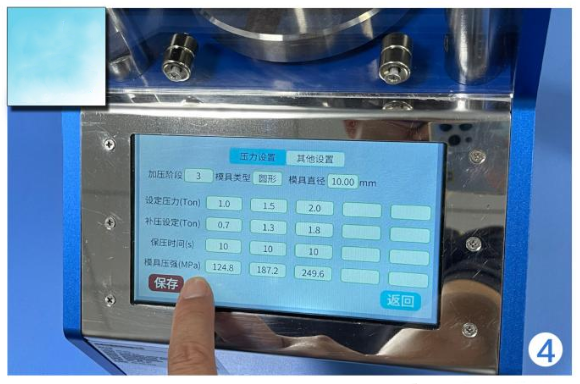

>Pressurization stage: 1-5 stages, it can be set arbitrarily

>Mold type: Cylinder, square, special-shaped(optional). When selecting cylinder, you need to accurately enter the diameter of the mold; when selecting square, you need to accurately enter the length and width dimensions of the mold; when the mold is not cylinder or standard square, you can only select the mold as a special-shape, there is no need to enter the mold size, and it is impossible to automatically calculate the pressure of the mold.

>Pressure setting: When the pressurization stage is selected as "1", only 1 pressurized data can be set, and so on; Select a few pressurization stages, and only a few pressurized data can be set; The pressure value is rising, and the subsequent stage cannot be less than the previous pressure value, but the maximum cannot exceed the tablet press pressure value. Each stage can independently set the pressure compensation value and holding time, when you do not need multiple stages of pressurization, it is recommended to set the pressure stage to "1", and the pressure value is reached to enter the holding pressure stage "See Holding Time Settings for details".

>Pressure compensation setting: It is when the real-time pressure reaches the pressure value you set (5.0 tons as the picture below), it enters the pressure holding stage. when the pressure falls to the pressure value (4.9 tons as shown in the picture below) during the pressure holding stage (the pressure holding time is 30 seconds as the picture below), ,the motor automatically starts the pressure compensation value and sets the pressure value to 5.0 tons, and continues the remaining pressure maintaining stage.

>Pressure holding time: No time limit (N seconds) can be set arbitrarily. When you do not need to hold pressure for too long, it is recommended to set a shorter time to release pressure faster and sampling faster.

>Mold pressure: According to the set pressure value, mold type and mold size, the mold bearing pressure will be automatically calculated. Special reminder, for small size molds you should pay special attention to the upper limit of mold pressure, do not set the pressure value arbitrarily to avoid mold damage

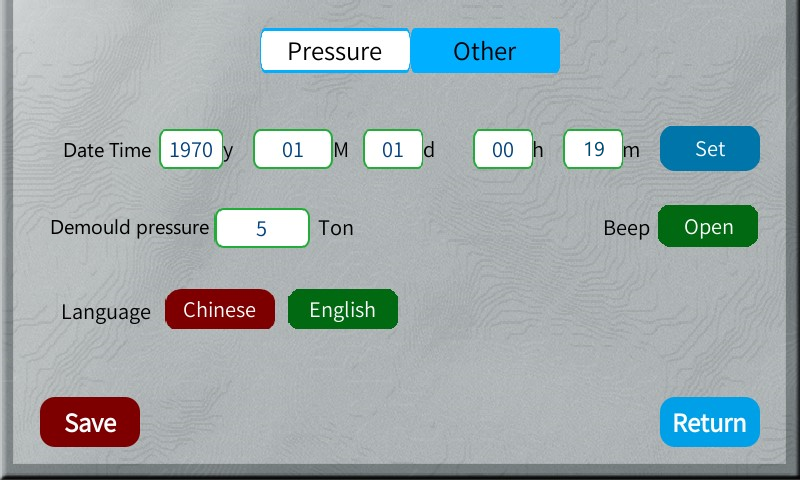

>Other settings: Set system time and demoulding pressure. Special attention should be paid to small molds, and the demoulding pressure should not be too high; if a large mold cannot be demoulding, the demoulding pressure can be increased appropriately, but be sure to pay attention to the changes in mold specifications and do not set it easily.

As shown above picture 2(pressure setting interface)

As shown above picture 3(other setting interface)

>Save and return: When all data settings are completed, click the “save” button to enter the main interface and start the pressurization program; When you do not need to change the data, you can directly click the “return” button to return to the main page.

2)Start Pressurization:

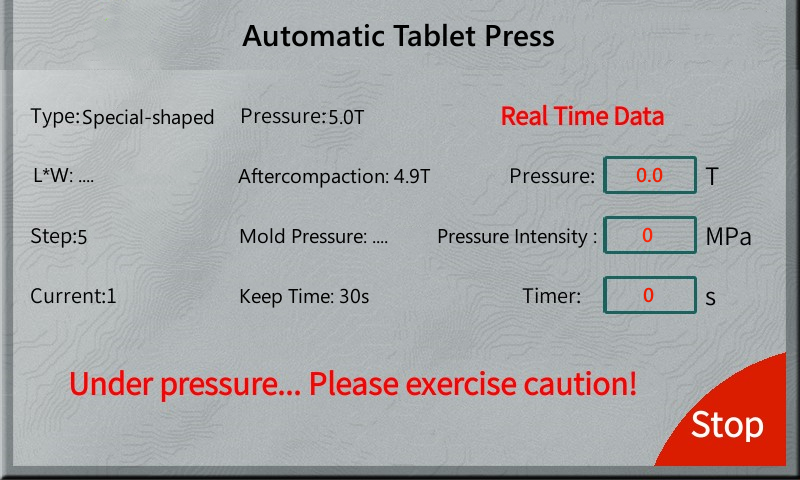

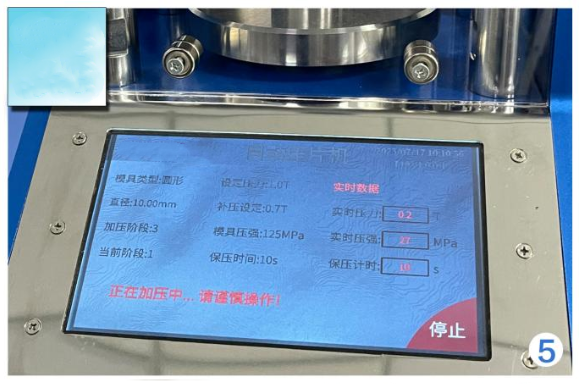

After the pressure is set, you can click the “start” button on the main interface to start pressurizing (Be sure to place the mold correctly before pressurizing. For details, please refer to "3" mold preparation steps on the next page). Please pay attention to the real-time pressure data on the main interface and the actual conditions of the mold to adjust the machine status in time; In case of emergency, you can click the “stop” button on the screen to stop pressurization or you can also directly press the “emergency stop switch” button on the top of the machine to emergency stop the machine.

As shown above picture 4 (starting the pressurization stage)

3)Data Management:

Each startup pressurized data are automatically saved, it’s easy to compare and check, deleted or emptied, and can be exported via U disk

4. Mold Operation Guide

A variety of molds are ever-changing, mold assembly, filling powder, making samples, demolding methods are different, the specific circumstances need to be combined with the specific analysis of the mold itself, here in the laboratory commonly used "ordinary cylindrical mold (Ф10mm)" as an example to make the following demonstration:

Laboratory common mold reference:

Ordinary cylindrical mold |

Ordinary square mold |

Ordinary flat mold |

Various/open flap molds |

Carbide mold |

Bi-directional pressurized mold |

Various/hot pressing molds |

Ring mold |

Spherical mold |

Infrared mold |

Boric acid mold for fluorescence |

Fluorescent special steel ring mold |

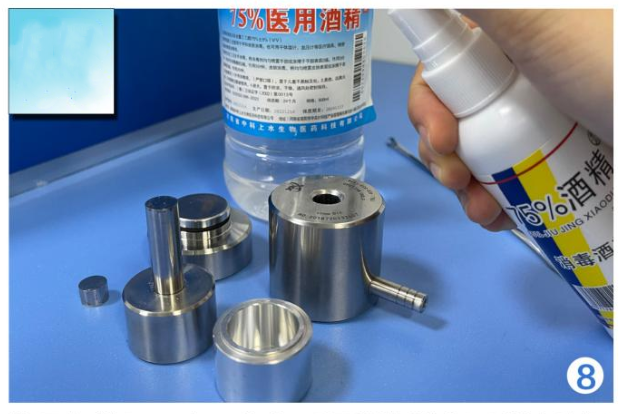

Mold assembly

The mold parts are arranged in a regular manner, the mold cavity is embedded in the base, and a gasket is placed to start adding powder.

Mold filling

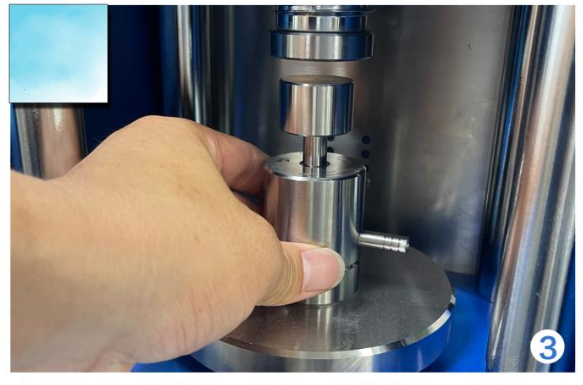

After the powder is added, insert the pressure rod and gently turn the pressure, make sure that the pressure rod is stable, and put it into the center of the tablet press.

Put in the tablet press

Ensure that the die is correctly placed on the tablet press, rotate the lead screw, and close the protective door by gently touching the die press rod with the wire bar head.

Set pressure

According to the experimental requirements and mold specifications, set the starting pressure, pressure holding time, etc., please be careful not to overpressure.

Starting pressure

After setting, click start pressure button, start pressure, in case of emergency, you can press the emergency stop switch.

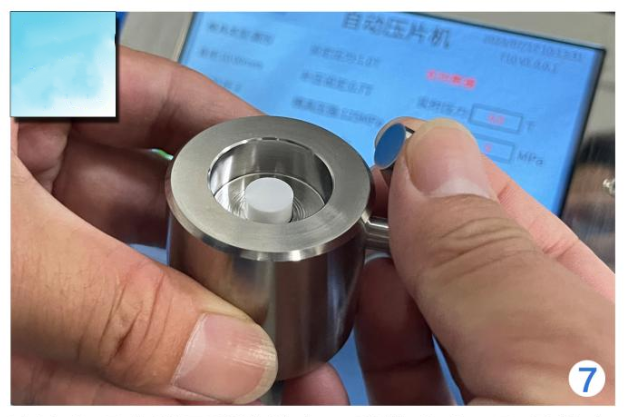

Demoulding

After pressure relief, take out the mold, invert the base, put on the film release sleeve, put back into the tablet press, start the release mold.

Take out sample

Please pay attention to the demoulding state of the mold, the demoulding success, immediately stop the pressure, take out the mold, take out the sample.

Mold maintenance

Every time the mold is used, be sure to wipe the surface with alcohol and remove dirt residue, keep dry.

5.Maintenance and Precautions:

1. After each test, clean up the residue on the surface of the machine in time, especially the scattered powder, water traces, oil stains etc. near the oil cylinder, screen and circuit, and pay more attention to the dirt of conductive or corrosive materials, and clean and maintain it in time

2. Check whether the machine bolts are firm from time to time. If problems are found, tighten them as soon as possible.

3. When the machine not in use for a long time, it is recommended to cut off the power supply and attach a thin film to the surface of the touch screen.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588