products categories

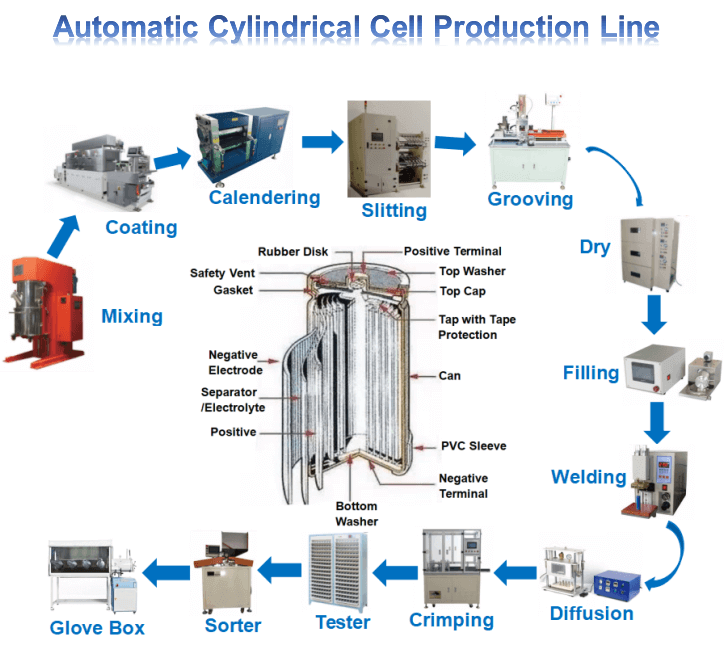

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

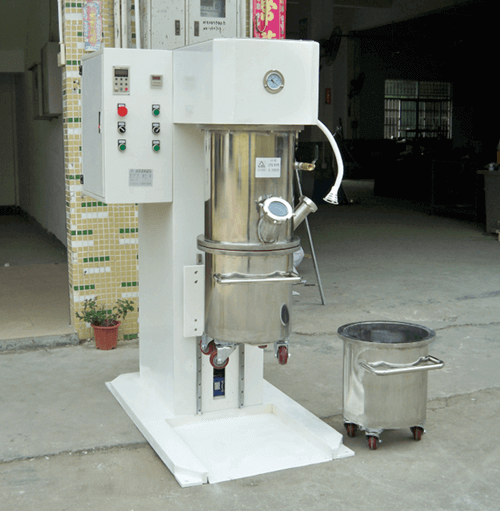

30L Planetary Vacuum Mixing Machine for Cathode and Anode Material Mixing

Model Number:

TMAX-PVM-30LCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5L Magnetic De-ironing Filtration Machine for Battery Slurry Before CoatingNext:

300W Laser Welding Machine for Cylindrical Cell Cap Welding

30L Planetary Vacuum Mixing Machine for Cathode and Anode Material Mixing for Battery Slurry Mixing

Ⅰ、Introduction

1. This TMAX-PVM-30L Planetary vacuum mixer machine is a set of vacuum mixing, dispersion equipment, suitable for

lithium electricity experiment process is anode paste mixing process, solder

paste, silica gel, chemical industry, etc

2. This lab planetary mixer Mixing motor adopts transmission frequency adjustment, can choose different rotational speed according to different process, different viscosity.

3. The vacuum planetary mixer is excellent for preparing LiCoO3, LiFePO4, Phosphors and ceramic slurry without gas bubble.

Ⅱ、Features

1. Adopt the industry leading soft sealing process, which can maintain the state of - 0.098mpa for more than 24 hours;

2. Adopt double precision guide pillar support, cylinder to push can body open and close, humanized design, precise and efficient;

3. The barrel body is made of 304 stainless steel with high quality. After finishing by large horizontal lathe, it is polished by precision automatic polishing machine to ensure high precision;

4. Double dispersing paddle design, make the material up and down and all around billow, make the slurry mix quickly and evenly;

5. The mixing motor adopts gearbox frequency conversion adjustment, and can select different speed and torque according to different process and viscosity;

Welcome new and old customers to contact us for slurry mixer.

Ⅲ、Specifications

Rated power |

5KW,380V; |

Agitation speed |

Dispersion speed: 0-1400RPM, Mixing speed: 0-70RPM Speed regulation by frequency converter |

Effective volume |

30L |

Barrel opening and closing mode |

The gearbox drives the barrel up |

Inner dimension of barrel |

Φ350mm×400mm |

Whole machine size |

1.6×1.1×7.5(m, H×L×W) |

Timing function |

It has timing function, and can set time 0-99 (H) at will. It can stop running automatically and keep vacuum state |

Weight of whole machine |

About 450kg |

Discharge port |

The discharge port is at the bottom of the barrel |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588