products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

2KW Portable Hand Held UV LED Light UV Curing Machine

Model Number:

TMAX-UV-1Input Power:

2KWDimension(L*W*H):

475L * 165W * 250H (mm)Net Weight:

15kgCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Portable UV Curing Machine Light UV Glue Curing MachineNext:

Desktop Ultraviolet (UV) Ozone Cleaner with Substrate Heater for Cleaning All Types of Substrates

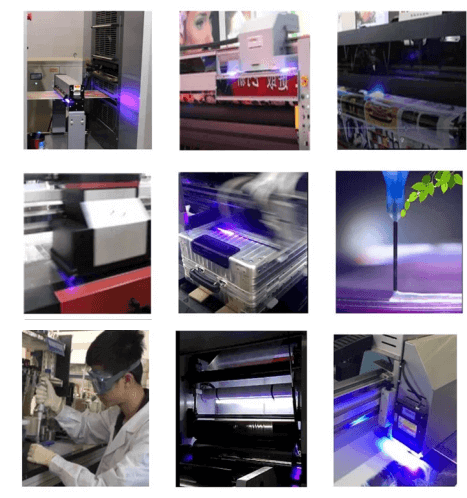

2KW Portable Hand Held UV LED Light UV Curing Machine

Introduction

It can be used in the following fields

1. Floor paint curing, model making. Scientific experiment of crafts forming

2. Production of special-shaped UV curing model and molding of crafts.

3. It is suitable for home furnishing, floor surface polishing and site construction

4. Suitable for UV glue, laboratory and temporary construction and simple maintenance

Features

1. This machine is beautiful in appearance, small in size, light in weight, space saving, wide in application and convenient in safe operation.

2. The UV Curing Machine can be moved to work, with strong randomness, flexibility and low efficiency.

3. The imported light source reflector refracts UV light to enhance the drying and curing effect.

4. Advanced heat dissipation system to ensure that the work is not affected and extend the life of the lamp.

Specifications

Irradiation distance |

80--200m |

power density |

80--120W/cm |

Spectral peak |

365nm |

Lamp tube |

2KW |

Cooling mode |

air cooled exhaust |

Brightness range value |

1000-9500mj / C ㎡ |

Power Supply |

220V 50Hz

|

Lamp wattage |

2KW |

Lamp tube length |

300 mm |

Lamp luminous area |

250mm |

Lamp Lifetime |

800H |

Weight |

15kg |

Size |

475L * 165W * 250H (mm) |

Package size |

700L * 495W * 350H (mm) |

Notice

1. When installing or replacing the lamp, the operator should avoid leaving oil stains on the lamp tube. Therefore, it is recommended to wear cotton gloves. The lamp body of the UV lamp is made of high-purity quartz. In order to improve the penetration rate of the UV light, please avoid any substances that may contaminate the surface of the lamp body attaching to the lamp body. It is recommended to wipe the lamp body with alcohol or a special cleaner for the UV lamp when the installation is completed Keep the surface clean;

2. UV lamp is usually installed on the equipment for use. Usually, the way to position the lamp head is to use a spring clamp device. Please ensure the good elasticity of its spring plate. Considering the expansion of the lamp head under long-term working conditions, it is recommended to keep a proper space during installation, rather than too tight, to avoid the explosion of the expansion after the lamp head is heated. UV light fixing machine also has Many precautions.

3. During the operation of the UV equipment, the heat of the lamp tube may cause the reflector to expand, shorten or bend, so the lamp tube cannot be installed too tightly, so that the change of the reflector will affect the lamp tube, resulting in the rupture of the lamp tube.

4. If there is no lead terminal at both ends of the lamp, installation should be more careful and ensure that the connector is free of corrosion.

5. If the machine is connected to the lamp with metal clip device, the connection part shall be tight and clean.

Application

Flatbed printing, Screen printing,Inject printing, Label printing, Silk screen, UV Coating&Varnish, Electronics bonding, UV Adhesive, Industrical Application ect.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588