products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

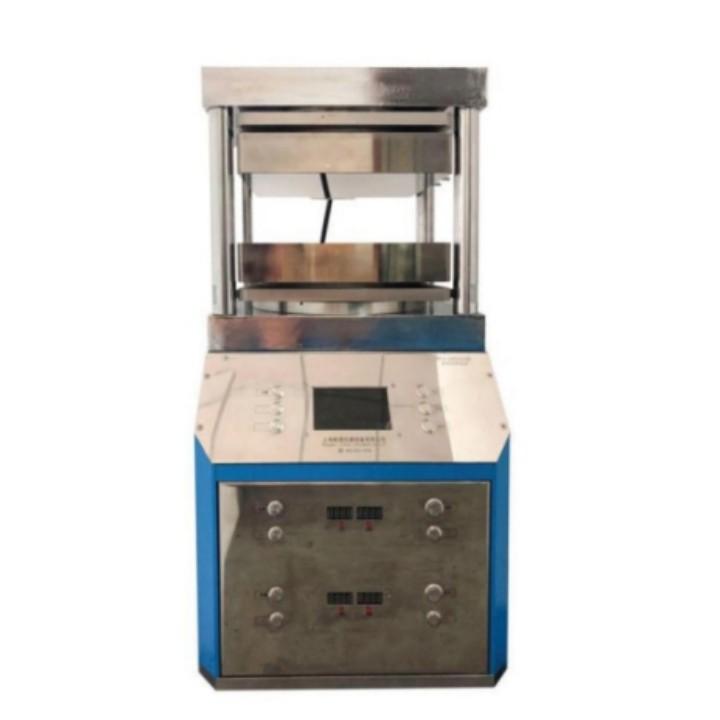

25T 30T 50T High Temperature Automatic Heat Press Optional Water Cooling Machine

Model Number:

TMAX-RYJ-600ZGCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab 180C 4KW Laminating Machine of PID Control Temperature Equipped with Gas Circuit Outage ProtectionNext:

High Vacuum Thermal Evaporation Coater With Three Kinds Of Evaporation Head Heat Evaporation Carbon Rod Molybdenum Boat Tungsten Wire Bar

25T 30T 50T High Temperature Automatic Heat Press Optional Water Cooling Machine

The new "RYJ-600ZG" series of automatic heat presses are based on the original RYJ-600Z model. The mold heating system is upgraded and improved. The maximum temperature can reach 500 degrees. The equipment is cooled by a stainless steel water-cooled heat insulation board to prevent the mold temperature from being too high. The sealing parts of the main machine cause damage and aging. This machine meets the needs of some users for high temperature testing. It is an ideal supporting equipment for engineering and technical personnel such as universities, research institutes, etc. to perform spectroscopy detection and analysis. It has been widely used in catalysis, rubber, plastics, films, polymers, metallurgical powders, Research and development of new power sources and new materials.

Main Parameter

Product name |

RYJ-600ZG1 |

RYJ-600ZG2 |

RYJ-600ZG3 |

RYJ-600ZG4 |

Pressure range |

1-25.0T |

1-30.0T |

1-50.0T |

|

Precision of pressure adjust |

0.1t |

0.1t |

0.1t |

|

Compression process |

fully automatic, program pressure/slow pressure - program pressure holding - program pressure replenishing - timing pressure relief |

|||

The holding time |

0-999.59(Min/Second) 999 minutes and 59 seconds |

|||

Type of thermostat |

PLC program temperature controller |

|||

Temperature control range |

RT-600.0℃,0.1 accuracy |

|||

Heating temperature of die |

RT-500.0℃ |

|||

Cooling method of die |

Water cooling (water cooler is optional) |

|||

Equipment Insulation Mode |

Imported insulation plate+Stainless steel water-cooled heat shield |

|||

Equipment structure |

Integrated structure, automatic program pressure control, temperature control |

|||

Die type |

Up and down 2 heating plates, polishing surface |

|||

Die size |

180*180mm |

200*200mm |

300*300mm |

400*400mm |

Overall size |

280*420*620mm |

280*420*620mm |

400*500*750mm |

500*600*780mm |

Power supply |

220/3000W |

220/3000W |

220/4000W |

220/8000W |

Equipment weight |

About 160kg |

About170kg |

About360kg |

About460kg |

Note |

A hot press, water cooling machine optional! Heating die can be customized according to user demand!!! |

|||

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588