products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

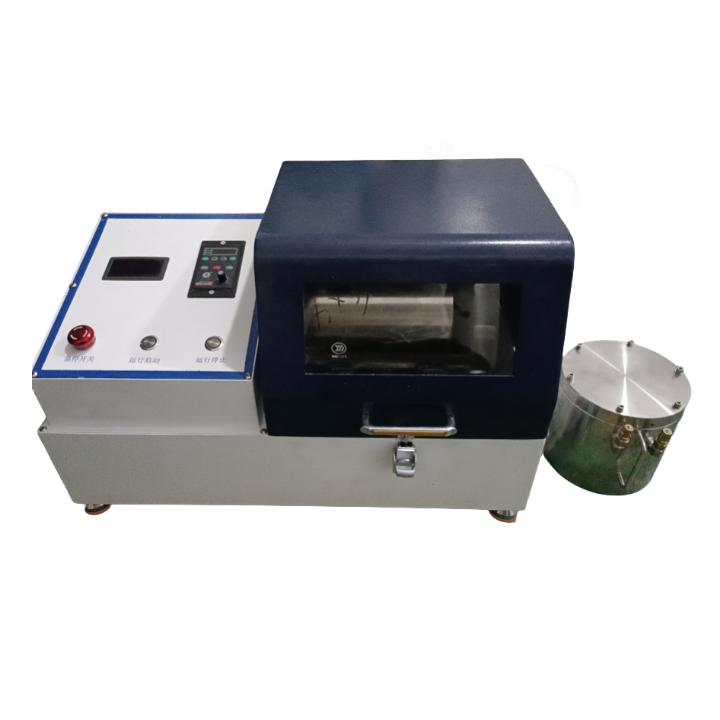

1L Vibrating Ball Mill Grinder Used for Fine Crushing

Model Number:

TMAX-JT-ZM-1LInput Power:

0.15KWDimension(L*W*H):

750*470*564mmNet Weight:

80KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab 125W Adjustable Amplitude Small Benchtop Automatic Vibrating Screen EquipmentNext:

1-100L Optional Vibrating Ball Mill Machine

1L Vibrating Ball Mill Grinder Used for Fine Crushing

The vibrating ball mill is driven by the motor through the winding coupling to produce vibration of the shaft equipped with eccentric block, which is transmitted to the stand. The stand is equipped with a ball mill cylinder, so the powder follows the vibration. Both sides and the bottom of the stand are equipped with springs connected to the machine base. Observed from the end surface of the ball mill cylinder, the trajectory of any powder body is a flat and curved. The height of the powder jumping is equal to 2 times the amplitude, the movement is mainly vibration, but due to inertia there is also a small amount of rotation.

Applications

Vibrating ball mill is the crushing equipment used in mineral processing and powder metallurgy, which is widely used in ceramics, non-metallic minerals, pigments, electronics, chemical industry, metallurgy, building materials, new materials, food and pharmaceuticals. It is used for fine crushing, the efficiency is 2 times higher than the general ball mill, has the advantages of simple structure, low cost and so on.

Parameters

Model |

JT-ZM-1L |

Reference external size (mm) |

600X320X420 |

Weight (KG) |

35KG |

Vibration motor power |

150W |

Amplitude (mm) |

5-8 |

Frequency (r/min) |

3000(Variable frequency adjustable) |

Ball milling jar volume |

50ML-1000ML |

Feeding particle size (mm) |

<5 |

Discharge particle size(mesh) |

200-2000(Related to material properties) |

Material of ball milling jar |

Stainless steel, agate, zirconia, tungsten carbide |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588