products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

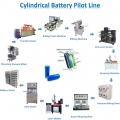

18650 26650 21700 32650 32700etc Cylindrical Cell Pilot Assembly Line for Cylindrical Cell Manufacturing

Model Number:

TMAX-CB-pilotType:

Semi-automaticCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPlace of Origin:

1 yearShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Auto Roll to Roll Tab Welding MachineNext:

Dia210*W330mm Roll to Roll Calander Hot Press Machine

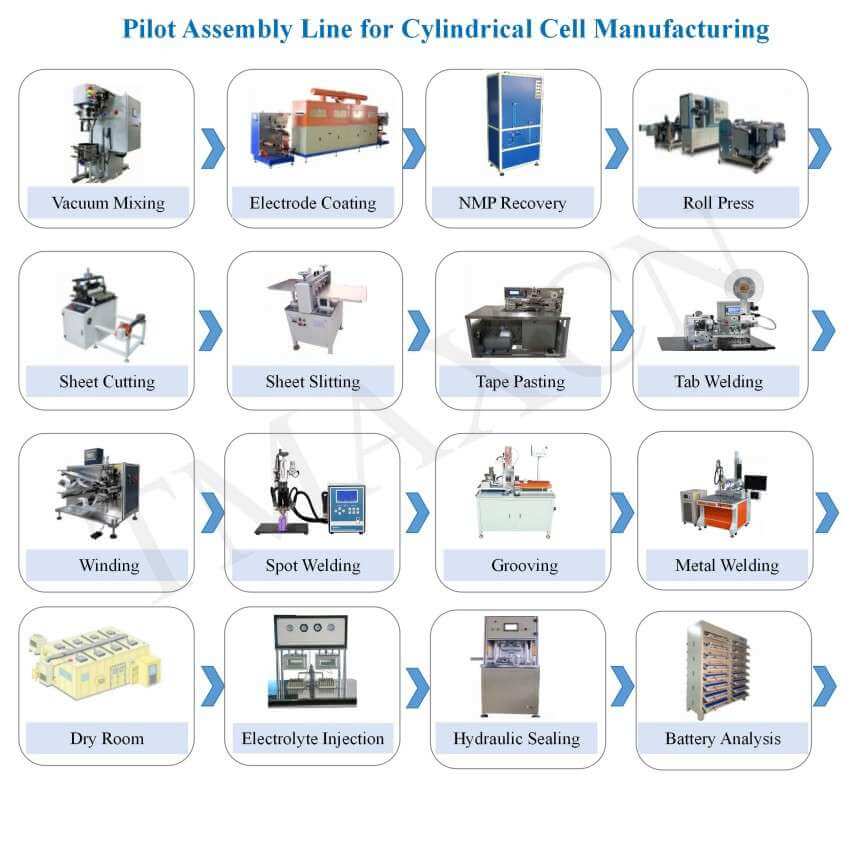

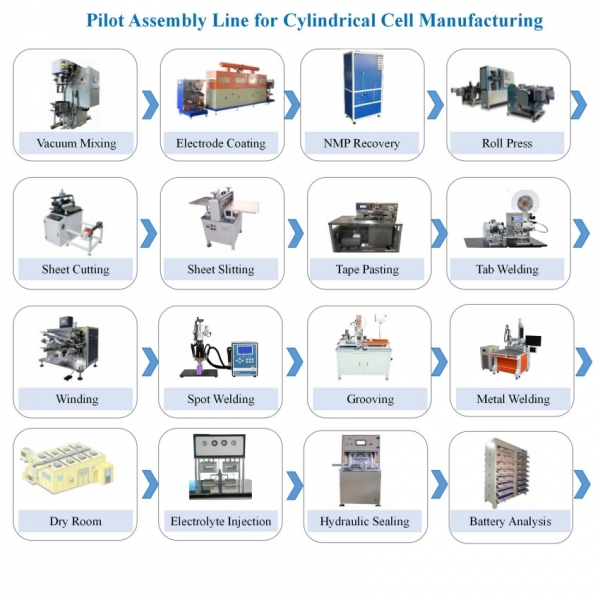

Ⅰ、Cylindrical Cell Pilot Line Equipment

1. Electrode preparation

Used to prepare the positive and negative electrodes, including machines for mixing, coating, pressing and drying the electrode materials and sheets.

2. Battery assembly

Used to assemble the positive and negative electrodes with the separator to form a battery cell, including machines for winding, welding, grooving and sealing the battery cases.

3. Electrolyte filling

Used to vaccum the battery case and fill electrolyte.

4. Formation and testing

Used to charge and discharge the battery cell to activate and stabilize cells and evaluate the performance of final batteries.

Ⅱ、Cylindrical Cell Components

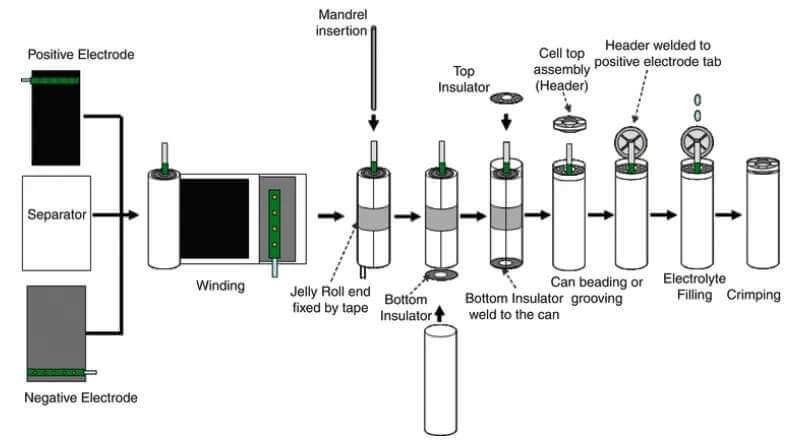

Ⅲ、Flow Chart for how Cylindrical Cells are Assembled

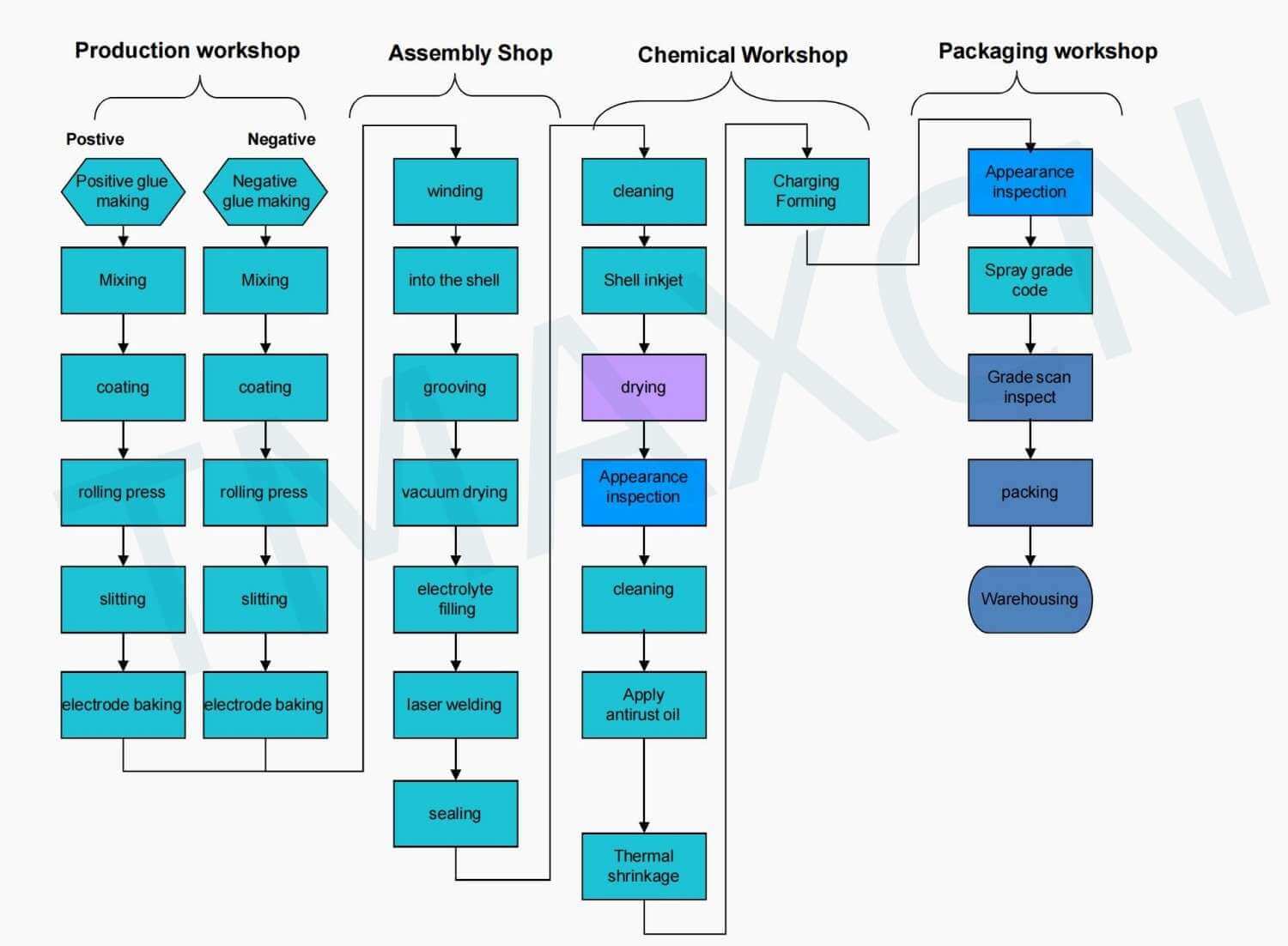

Ⅳ、Production workshop

Ⅴ、TMAX Cylindrical Cell Pilot Line Equipment and Process

No. |

Process |

Equipment Name |

1 |

Raw material baking |

Vacuum Drying Oven with Tri-Level Shelf Heating Modules |

2 |

Vacuum Mixing |

Large Planetary Vacuum Mixer with Vacuum Pump and Water Chiller |

3 |

Slurry viscosity Test |

Digital Touch Screen Viscometer |

4 |

Vacuum Mixing |

Turnover Bucket |

5 |

Magnetic De-Ironing Filtration |

Magnetic De-ironing Filtration System for Battery Electrode Slurry |

6 |

Electrode Coating |

3 Rollers Battery Electrode Intermittent Coating Machine |

7 |

Waste Gas Treatment |

Solvent Processing System Waste Gas Treatment Equipment |

8 |

Roll press |

Roll to Roll Pressure Controlled |

9 |

Electrode Sheet Cross Cutting |

Lithium Battery Electrode Sheet Cutter Machine for Battery Big Electrode |

10 |

Electrode Sheet Slitting |

Battery Electrode Roll Slitting Machine |

11 |

Sticking glue of lithium ion battery electrode |

Lithium ion Battery Electrode Piece Sticking Machine |

12 |

Tab Welding |

Al Tab Ni Tag Ultrasonic Welding Machine |

13 |

Electrode Winding |

Automatic Precision Winding Machine |

14 |

Put the cell into the battery shell, and weld the negative electrode lug and the negative electrode shell with a spot welder |

Precision High Frequency Inverter DC double Pulse Spot Welding Machine |

15 |

Short circuit tesing |

Short Circuit Tester |

16 |

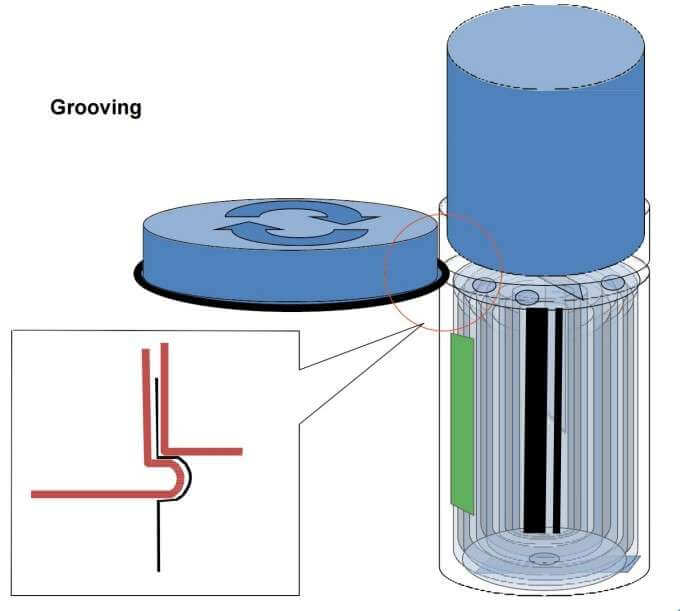

The battery shell is formed by rolling groove, which is convenient for sealing. |

Floor-stand Automatic Grooving Machine for Batch Processing of Cylindrical battery Castings |

17 |

Cylindrical Cell Cap Laser Welding |

Laser Welding Machine |

18 |

Filling the electrolyte into the battery |

Automatic Precision Electrolyte Injection Station for Cylindrical Cell Batteries |

19 |

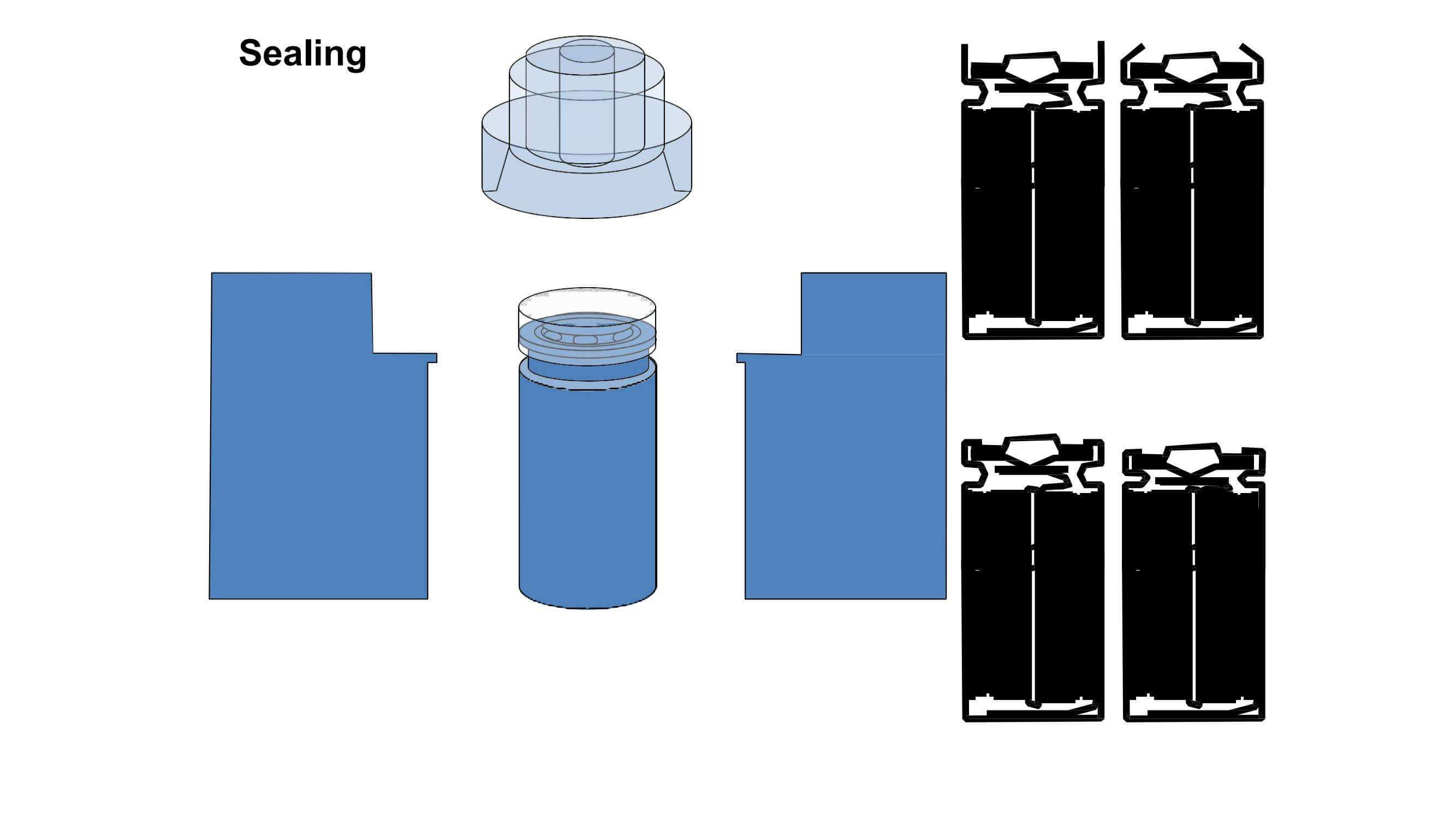

Sealing the cylindrical cell cases |

Automatic Cylindrical Cell Crimping Machine |

20 |

Cell Formation and capacity testing |

512 Channel Lithium Ion Battery Tester Equipment |

21 |

Print numbers to cylindrical cells |

Continuous Small Character Ink Jet Printer |

22 |

Remove the moisture from the battery production process to ensure the quality of the battery |

Dehumidification and Drying System |

23 |

Vacuum pumping |

Monoblock Rotary-vane Vacuum Pump |

24 |

Provide compressed gas for each battery production machine |

Helical Compressor |

Ⅵ、 Machine process description

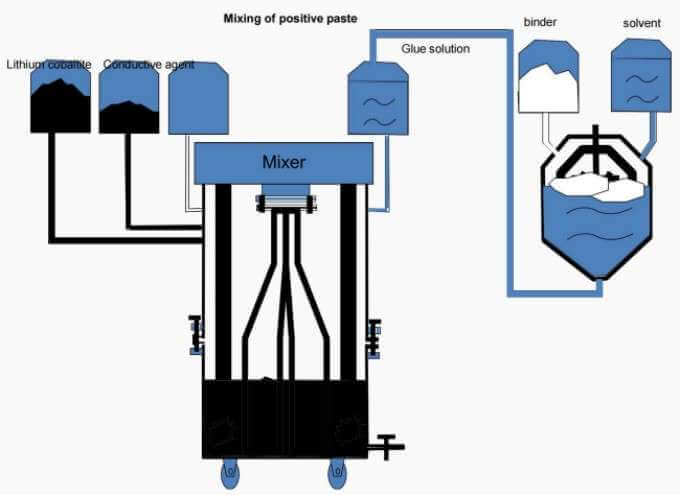

Accurate mixing:

During mixing, a homogeneous coating paste (slurry) is produced that is applied to the electrode foils during the subsequent coating process.

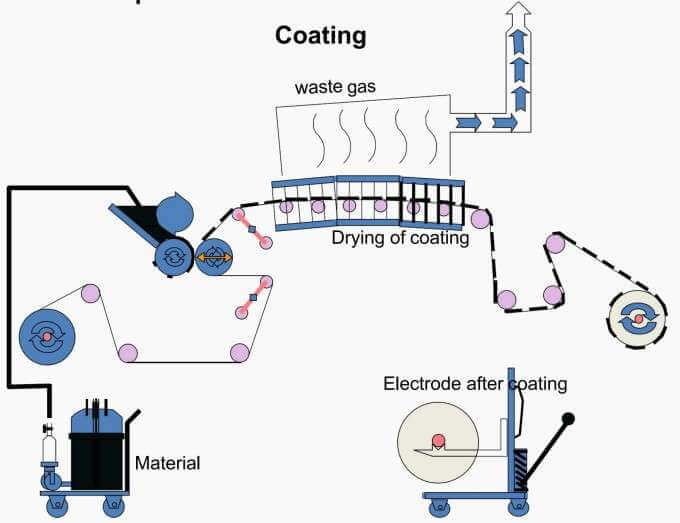

Film coating:

Coating machine with various heating designed to produce films with consistent thickness.

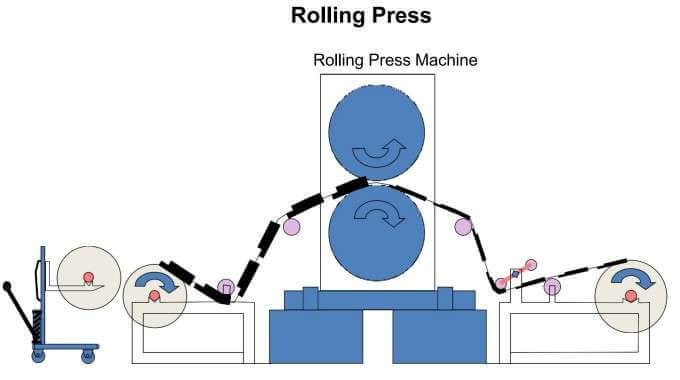

Calender:

Roll the dried electrode to reduce the thickness and increase the density.

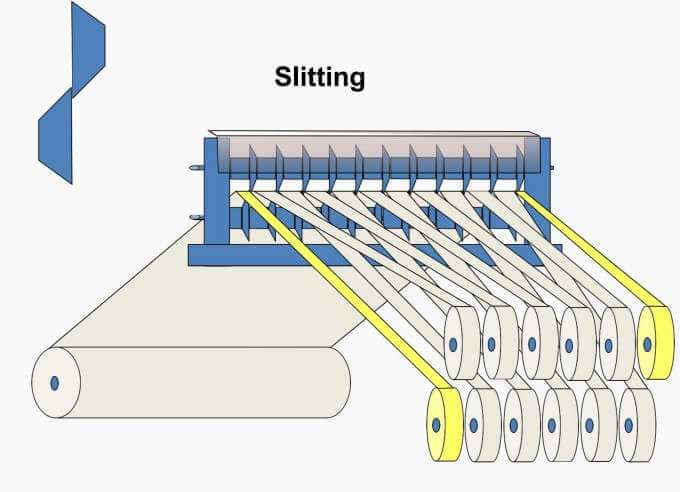

Slitting:

Slit the positive and negative plates according to the width requirements.

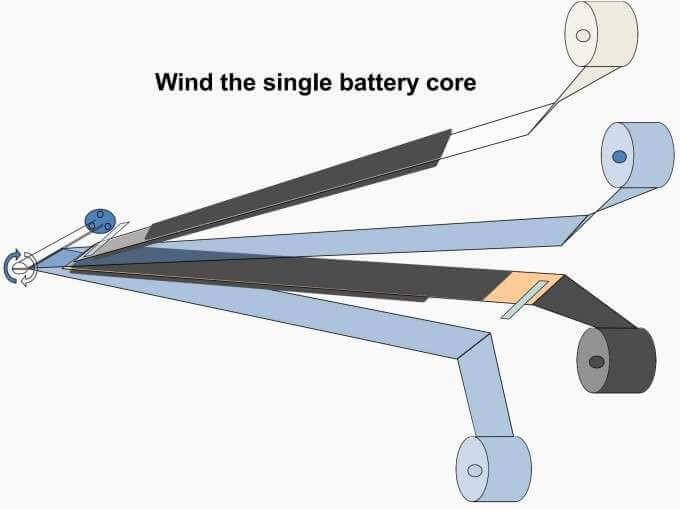

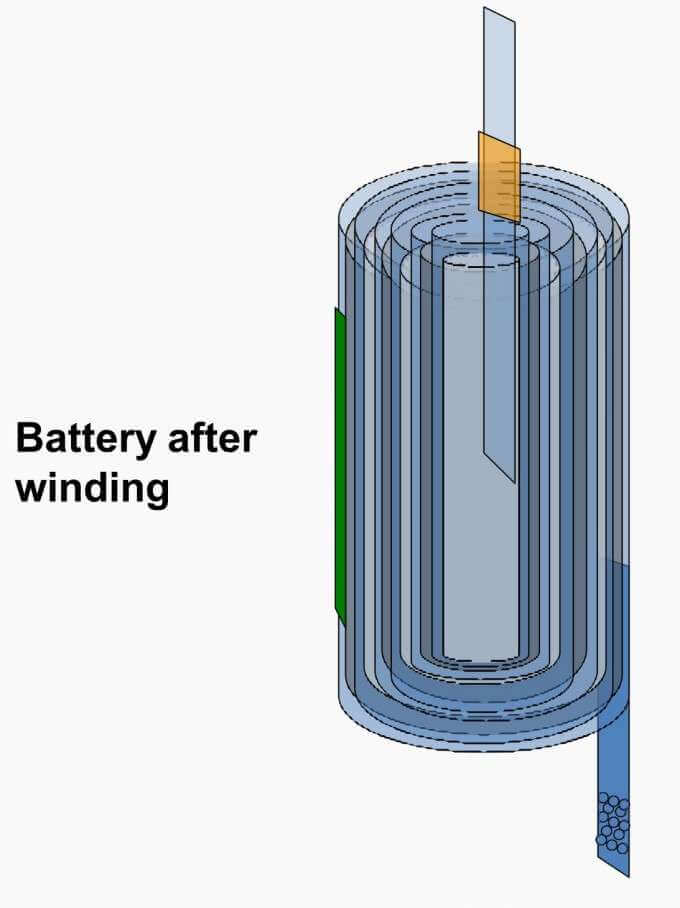

Winding:

Place the electrode piece and separator on the winder for winding, and the stacking order is as follows: (separator+ positive + separator +negative ).

Welding:

Put the cell into the battery shell, and weld the negative electrode tab and the negative electrode shell with a spot welder.

Grooving:

The battery shell is formed by rolling groove,which is convenient for sealing.

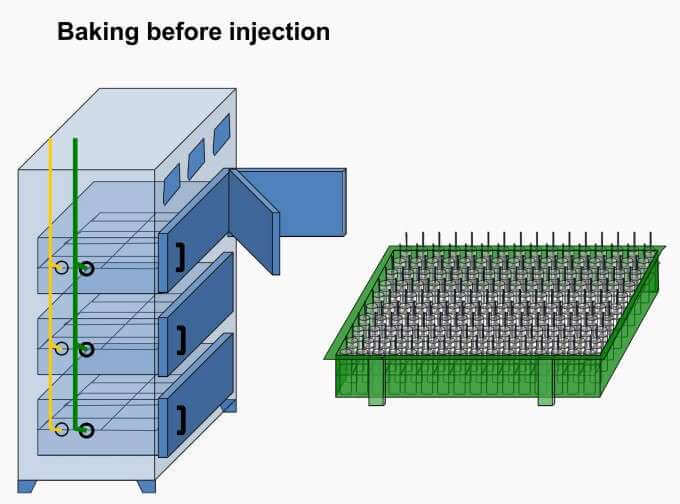

Baking before injection:

Sealing:

Ⅶ、Procurement process

TMAX follows a comprehensive procurement process to ensure a seamless experience for our customers.

Initial Consultation: We have an in-depth discussion with the customer to understand their battery production requirements, machine specifications, and budget constraints.

Proposal Preparation: Based on the consultation, we create a detailed proposal that outlines our recommended battery-making machines, pricing, delivery timelines, and additional services or support.

Proposal Presentation: We present the proposal, highlighting the features and benefits of our machines, addressing customer questions, and explaining how our solution meets their needs.

Negotiation and Agreement: We engage in negotiations to address concerns and modify the proposal if needed, aiming to reach a mutual agreement on pricing, terms, and conditions.

Purchase Order: The customer issues a purchase order (PO) that formalizes the agreement, specifying quantities, prices, delivery dates, and contractual obligations.

Order Fulfillment: We manufacture or source the battery-making machines according to agreed specifications, conducting quality control checks to ensure high performance and reliability.

Shipment and Delivery: We handle packaging, transportation, and customs clearance, providing tracking information and updates on the shipment's status.

Installation and Training: Our technicians offer installation services and comprehensive training on machine operation, maintenance, and troubleshooting.

Post-Sales Support: We provide ongoing customer support, including assistance with spare parts, maintenance, upgrades, and expansions, to ensure customer satisfaction.

By following this streamlined procurement process, we deliver high-quality battery-making machines tailored to our customers' requirements while providing excellent support throughout their lifecycle.

Ⅷ、Manufacturing Cycle and Planning

No. |

Project |

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

||||||

1 |

◎ Confirmation of idea/plan/specification |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

◎ Customized design for key parts |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

◎ Mechanical part design |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

◎ Control part design |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

◎ Procurement of processed parts/outsourced parts |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

◎ Mechanical assembly |

|

|

|

|

|

|

|

|

|

|

|

|

7 |

◎ Electrical debugging |

|

|

|

|

|

|

|

|

|

|

|

|

8 |

◎ Single test |

|

|

|

|

|

|

|

|

|

|

|

|

9 |

◎ Linkage trial operation and on-site customer placement |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

◎ Trial run/final acceptance |

|

|

|

|

|

|

|

|

|

|

|

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588