products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

15T Laboratory Small Manual Hydraulic Press Machine for Material Pressing

Model Number:

TMAX-SYPCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

300℃ 30T Manual Hot Press with Double Heating PlateNext:

300c Cylindrical Lab Electric Heating Press Machine for Scientific Research

15T Laboratory Manual Hydraulic Press Machine for Material Pressing

Our Laboratory Hydraulic Pressing Machine has the advantages of small volume, high pressure and high precision of pressure control. It is applied to chemical industry, such as: scientific research, pharmaceutical, teaching, testing, catalysis and so on. In addition, this product can also be used with Fourier infrared spectrometer. Fluorescence spectrometer supporting sample preparation, can replace similar imported products.

It can also be used with Ca-Fe analyzer, infrared spectroscopy (IR) analyzer and X-ray fluorescence (XRF) analyzer to analyze the pressed samples.

Features

1.Small size, light weight,No oil linkage, easy to carry.

2.Digital display pressure gauge 0.1MPa,Pressure control is more accurate.

3.The oil pool is easy to replace oil on the main surface of the host, and the hydraulic oil filter is added to the oil path.

4.Special plunger, special custom sealed structure, good sealing effect, no oil leakage

5.The upper plate adopts six angle screws in electroplating sunk head. It is beautiful and saves space.

6.One main plate structure, oil pool, main board, oil cylinder, on one body, no seal connection.

7.Lengthening spring, the rebound effect is good, not easy to deform, can realize the oil cylinder 30mm return no deformation.

8.The Aluminum Alloy handwheel, beautiful, practical, durable, not easy to damage.

Specifications

Model |

TMAX-SYP-3T |

TMAX-SYP-5T |

TMAX-SYP-12T |

TMAXSYP-15TB |

TMAX-SYP-15TA |

|

Pressure range |

0-3T (0-28.8MPa) |

0-5T (0-31.4MPa) |

0-12T(0-30MPa) |

0-15T(0-30MPa) |

||

Piston diameter |

φ35mm |

φ45mm |

φ70mm |

φ80mm |

||

Analog pressure gauge |

Analog pressure gauge is included in the standard package, dual scale display: Mpa and Ton |

|||||

Digital pressure gauge (optional) |

Digital display 0.00-40.00mpa, accuracy 0.01Mpa (only with "s" type) |

|||||

Maximum piston stroke |

30mm |

|||||

Pressurization mode |

Manual pressurization / manual slow pressurization |

|||||

Pressure stability |

≤1MPa/10min |

|||||

Overall structure |

Patented technology of integrated structure, no sealing connection of equipment, reducing oil leakage point |

|||||

Diameter of worktable |

φ80mm |

φ90mm |

||||

Number of columns |

2 columns |

2columns |

4 columns |

|||

Working space (W×H) |

96×130mm |

96×130mm) |

140×150mm |

80×130mm |

||

Machine dimensions (L×W×H) |

225×155×380mm |

225×155×380mm |

245×175×390mm |

245×175×390mm |

||

Machine weight |

28kg |

28kg |

38kg |

40kg |

||

|

||||||

Model |

TMAX-SYP-24T |

TMAX-SYP-30T |

TMAX-SYP-40T |

TMAX-SYP-60T |

||

Pressure range |

0-24T(0-34MPa) |

0-30T(0-31.5MPa) |

0-40T(0-30MPa) |

0-60T(0-34MPa) |

||

Piston diameter |

φ95mm |

φ110mm |

φ130mm |

φ150mm |

||

Analog pressure gauge |

Analog pressure gauge is included in the standard package, dual scale display: Mpa and Ton |

|||||

Digital pressure gauge (optional) |

Digital display 0.00-40.00mpa, accuracy 0.01Mpa (only with "s" type) |

|||||

Maximum piston stroke |

30mm |

40mm |

50mm |

50mm |

||

Pressurization mode |

Manual pressurization / manual slow pressurization |

|||||

Pressure stability |

≤1MPa/10min |

|||||

Overall structure |

Patented technology of integrated structure, no sealing connection of equipment, reducing oil leakage point |

|||||

Diameter of worktable |

φ105mm |

φ120mm |

φ140 |

φ160mm |

||

Number of columns |

4 columns |

|||||

Working space (W×H) |

80×150mm |

92×160mm |

115×185mm |

185×250mm |

||

Machine dimensions (L×W×H) |

245×175×415mm |

275×195×420mm |

295×215×500mm |

405×240×565mm |

||

Machine weight |

42kg |

56kg |

75kg |

120kg |

||

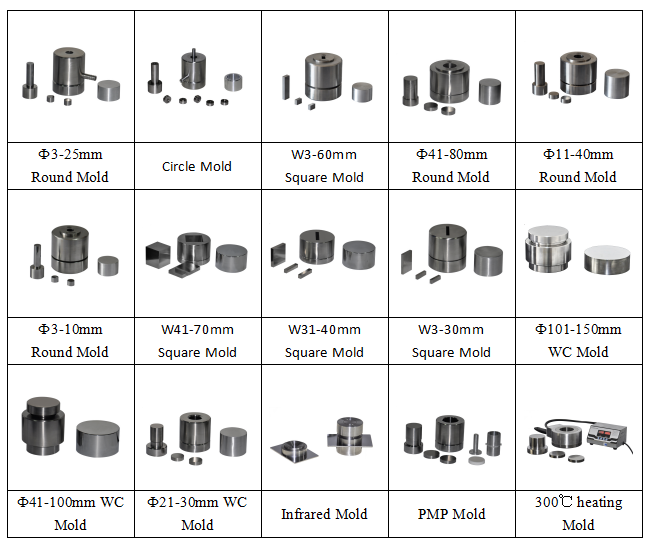

Hydraulic Press Mold

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588